Centering non-deformation hole grinding pitch circle clamp

A fixture and pitch circle technology, used in grinding machines, manufacturing tools, grinding workpiece supports, etc., can solve the problems of inability to popularize in a large area, difficult to replace the positioning spherical surface, and reduced centering accuracy, and achieve simple structure, long service life, The effect of simplifying loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

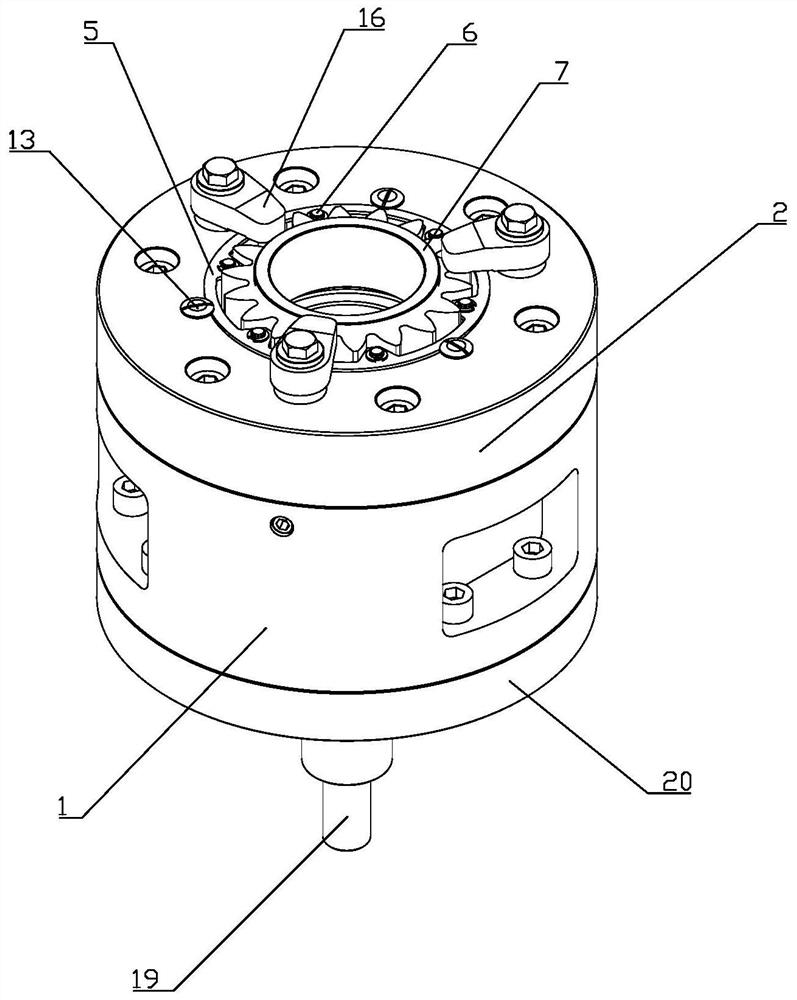

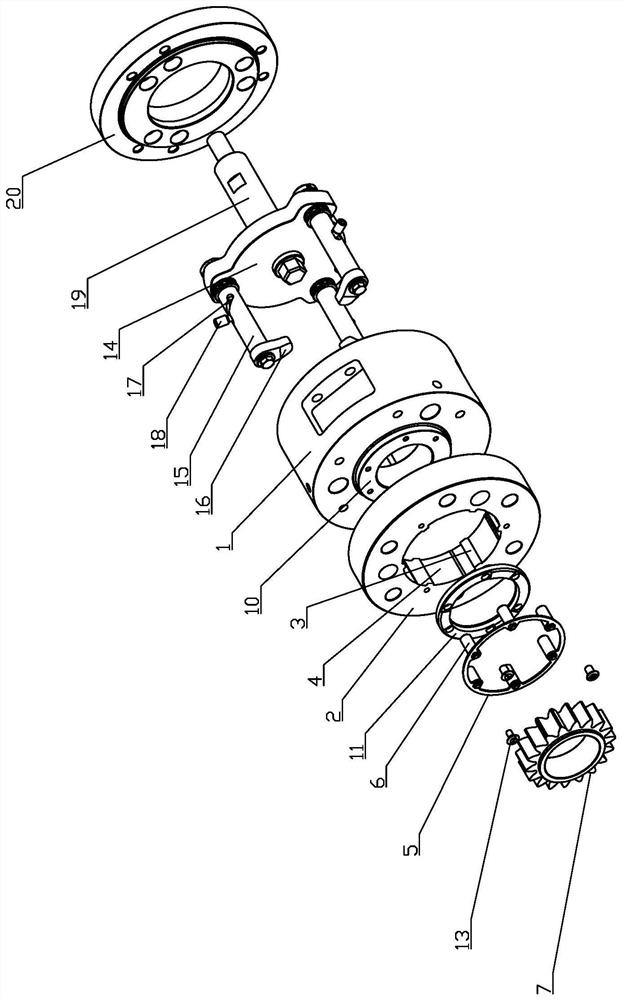

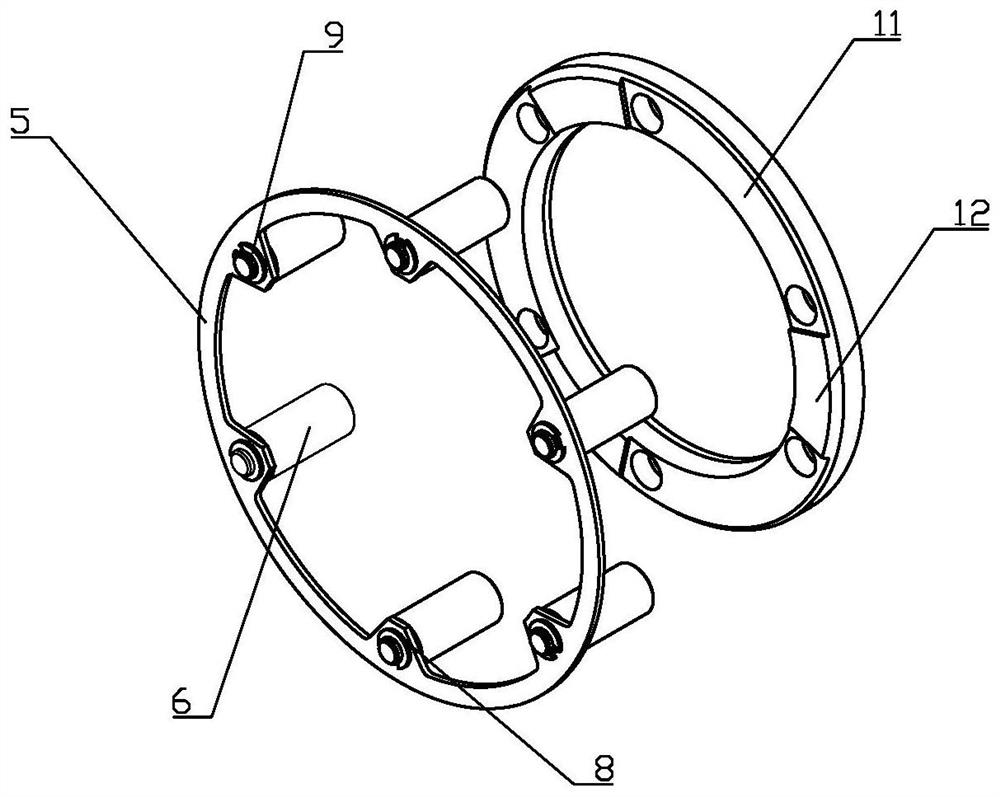

[0032] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-4 :

[0033] A centering and non-deformable grinding hole pitch circle fixture, comprising a clamp body 1, an inner cam 2 is centered on the clamp body 1, and several centering notches 3 and The positioning curved surface 4, the positioning curved surface 4 is distributed in an Archimedean spiral, the clamp body 1 is provided with a clamp centering table 10, and the clamp centering table 10 cooperates with the centering notch 3 to center the inner cam 2. A centering assembly is provided for rotation inside the inner cam 2, and the centering assembly includes an annular toothed cage 5 and a number of positioning rods 6 loosely connected to the toothed cage 5, and the positioning rods 6 are connected to the toothed cage 5. The positioning curved surface 4 contacts and connects the positioning workpiece 7 . In this embodiment, the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com