Special processing equipment for wedge-shaped sealing surface of wedge top type ball valve body

A technology for processing equipment and sealing surfaces, which is applied in the field of special processing equipment for sealing surfaces, can solve problems such as prone to errors and difficult to ensure accuracy, and achieve high grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

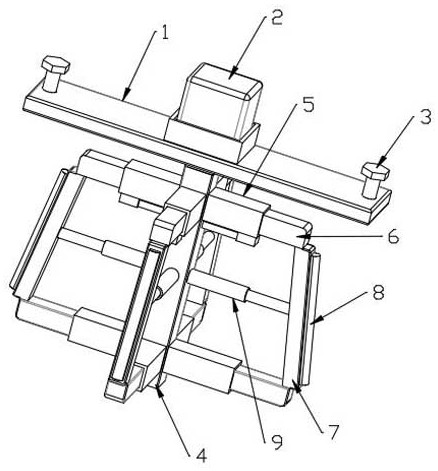

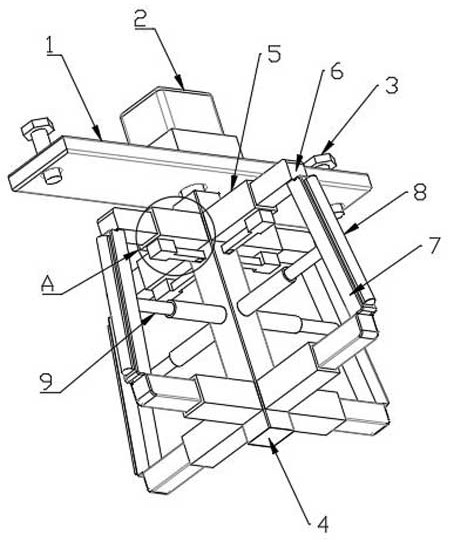

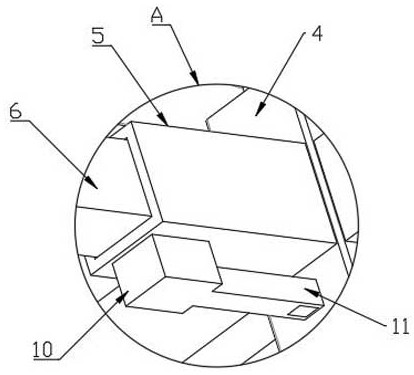

[0028] refer to Figure 1-6 , a special processing equipment for the wedge-shaped sealing surface of the wedge-top ball valve body, the processing equipment includes:

[0029] The fixing component is used to connect with the flange of the ball valve body to fix the processing equipment on the ball valve body;

[0030] The grinding assembly includes a rotating rod 4 and a plurality of grinding rollers 8. The rotating rod 4 is arranged in the middle of the fixed assembly. Angle, when the grinding roller 8 is in contact with the sealing surface and rotates around the axis of the rotating rod 4, the sealing surface can be polished;

[0031] The driving part 2 is arranged on the fixed assembly, and is used to provide the driving force required for the rotating rod 4 to rotate around its own axis.

[0032] In the embodiment of applying the above technical solution, the preset included angle between the grinding roller 8 and the rotating rod 4 corresponds to the included angle betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com