An Optimal Blanking Method for Chip Testing Automated Production Line

An automated production line and chip testing technology, applied in automated testing systems, electronic circuit testing, electrical measurement, etc., can solve the problems of machine space occupation, increased machine size, and insufficient compactness of the machine, so as to improve timeliness and The effect of design cost reduction, high practical significance and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Examples of the present invention are as follows.

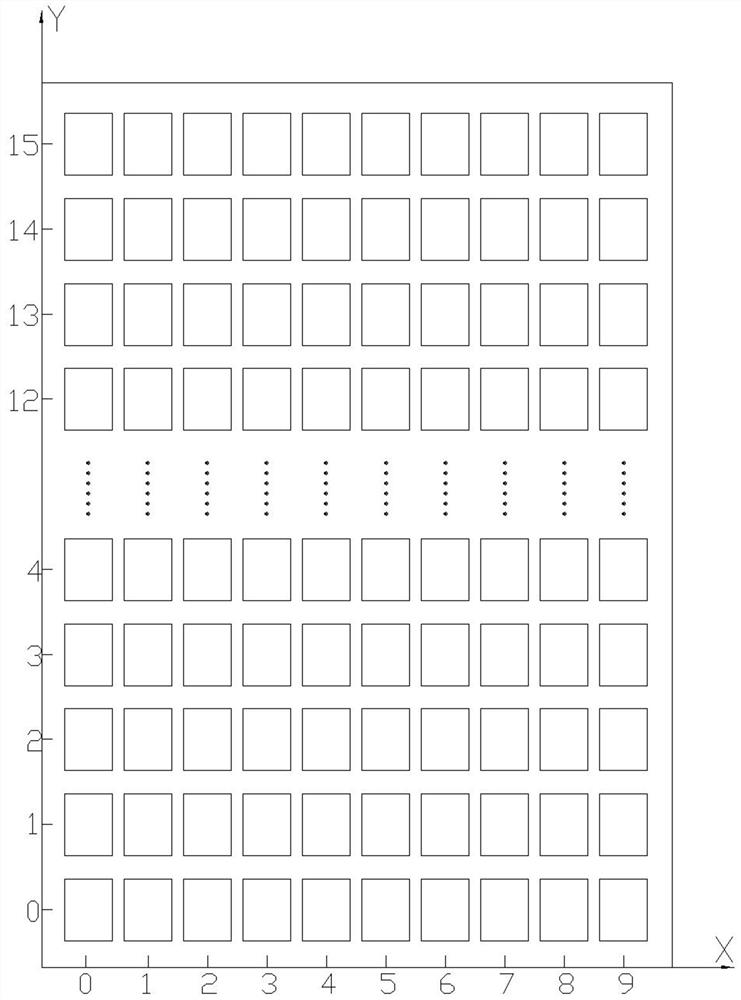

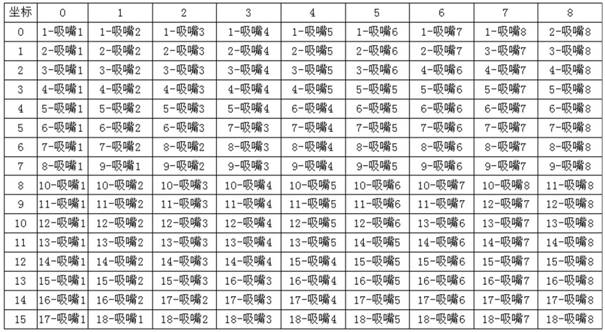

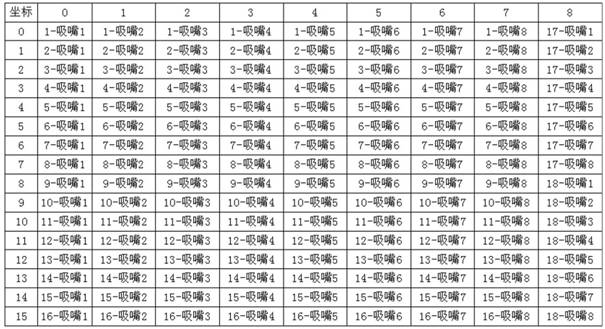

[0019] like figure 1 As shown, in the method of the present invention, the blanking equipment of the automatic chip testing production line is set as a tray, and the tray is provided with vertical and horizontally distributed chip positioning grooves, and a coordinate system is established with the vertically and horizontally distributed trays of the chip positioning grooves, and the horizontal direction of the tray is set as The X-axis is set as the Y-axis in the longitudinal direction of the tray, and the chip positioning grooves set on the tray are set to have m rows×n columns, where m and n are both natural numbers greater than 1, and m>n, and each chip positioning groove is set Set as a coordinate point, set the chip positioning slot of the first row and the first column as the origin of the coordinate system, the coordinate value is (X, Y)=(0,0), and the coordinates of the chip positioning slot of the first row a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com