Hydrogen refueling station-based hydrogen purification device

A purification device and hydrogen refueling station technology, applied in hydrogen/synthesis gas production, hydrogen separation, inorganic chemistry, etc., can solve the problems of low efficiency of cooling and impurity removal, difficult replacement and cleaning of filter devices, etc., to increase the cooling contact area, improve Heat transfer efficiency and the effect of expanding the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

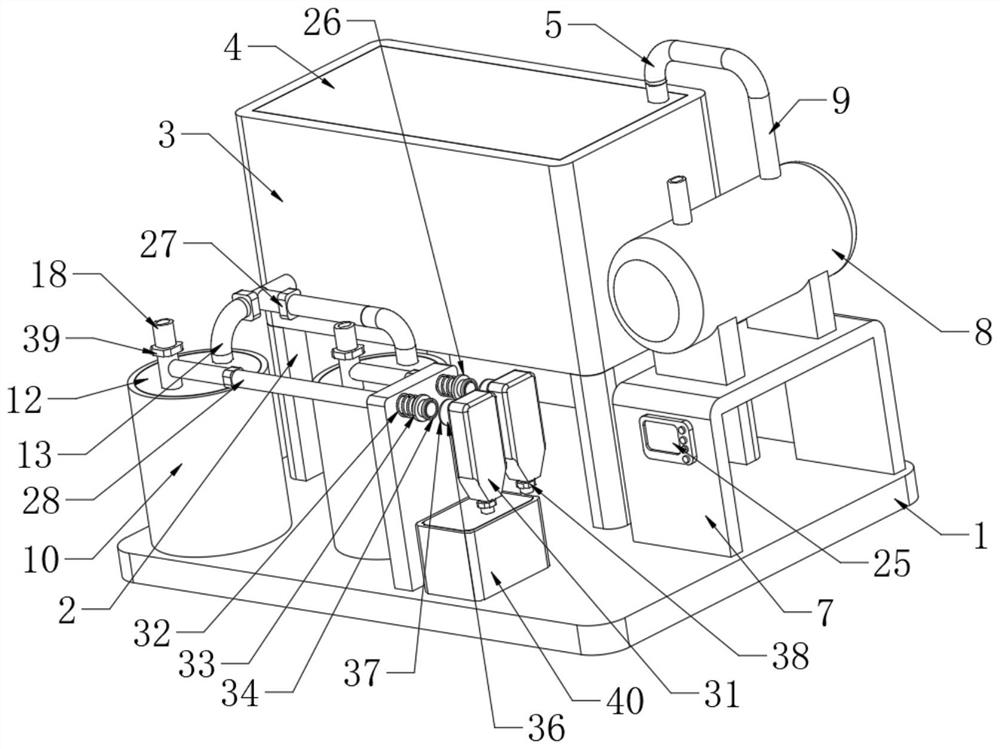

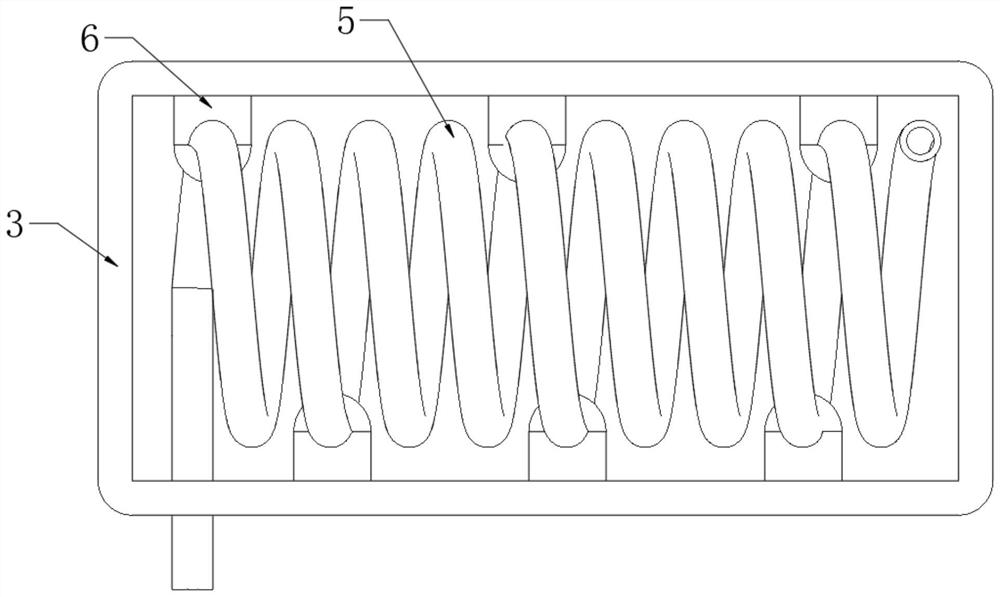

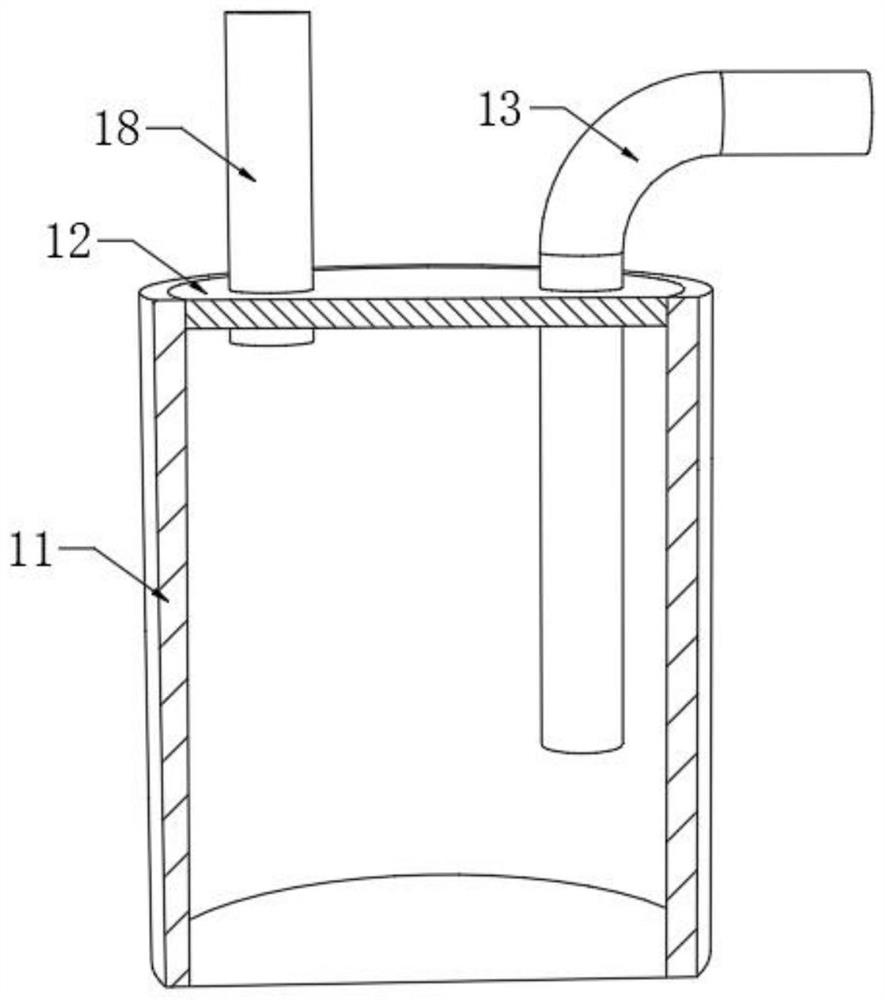

[0028] In the specific implementation process, please refer to figure 1 , figure 2 and Figure 8 As shown, a hydrogen purification device based on a hydrogen refueling station includes a base plate 1, a support column 2 and a cooling box 3, and four support columns 2 are fixedly connected to one side of the upper surface of the base plate 1 at equal distances, and the four support columns The top of the column 2 is fixedly connected with a cooling box 3, the top of the inner wall of the cooling box 3 is fixedly connected with a box cover 4, the cooling box 3 is provided with a spiral condenser tube 5, and both sides of the inner wall of the cooling box 3 are fixedly connected with A fixed base 6, and the outer surface of the spiral condenser tube 5 is fixedly installed with a plurality of fixed bases 6 respectively, a U-shaped frame 7 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com