Cooling system for fumaric acid

A cooling system, fumaric acid technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of affecting cooling efficiency, cooling system can not be continuous, small contact area, etc. problems, to achieve the effect of improving cooling efficiency, increasing cooling contact area, and strong continuous cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

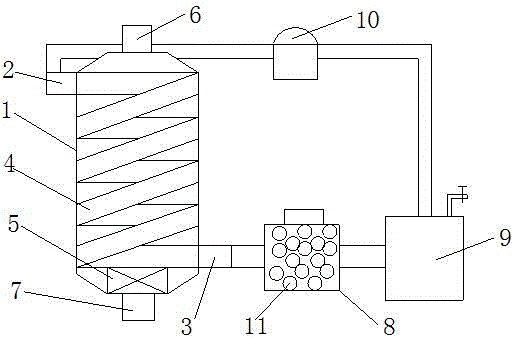

[0010] Such as figure 1 A kind of cooling system that is used for fumaric acid is shown, comprises reactor 1, and described reactor 1 top is provided with water inlet 2, and lower part is provided with water outlet 3, and between water inlet 2 and water outlet 3 is provided with pipeline 4 Directly connected, the pipeline 4 is fixed in the reactor 1 by the bracket 5, the top of the reactor 1 is provided with a material inlet 6, and the bottom is provided with a material outlet 7; the water outlet 3 is connected to the cooling box 8, and the cooling box 8 is connected to the storage tank The water tank 9 and the water storage tank 9 are connected to the water inlet 2 through the water pump 10 , the pipeline 4 is in a spiral shape in the reactor 1 , and the cooling box 8 is filled with ice packs 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com