water tank for vehicle

A technology for water tanks and vehicles, which is applied in the cooling of engines, machines/engines, mechanical equipment, etc., can solve problems such as failure to meet the needs of trial users, cracking of the inner wall of the box, limited heat dissipation effect, etc., to ensure smooth waterways. , The effect of increasing the cooling contact area and shortening the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

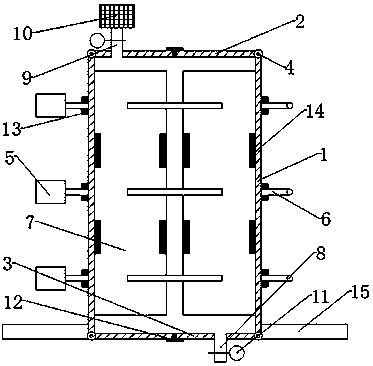

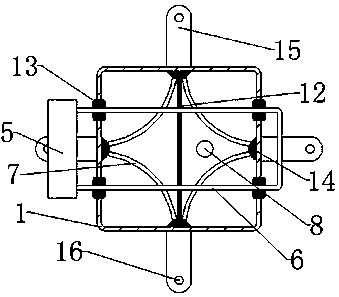

[0015] figure 1 Show the specific embodiment of a kind of vehicle water tank of the present invention: this vehicle water tank, water tank body 1 is the rectangular parallelepiped sleeve of 50 * 50 * 80CM, wall thickness 1 centimeter, and water tank body 1 bottom 4 sides are provided with long 30CM base 15, Each of the four bases 15 is provided with a screw hole 16 with a diameter of 10 cm. The water tank body 1 is connected with the upper cover plate 2 and the lower cover plate 3 through the sealing hinge 4, and the upper cover plate 2 and the lower cover plate 3 are divided into left and right parts, which are connected by a detachable sealing strip 12 when combined, and the lower cover plate 3 A drainpipe 8 with a diameter of 8CM is provided on the top, and a valve 11 is provided on the 8th drainpipe. The upper cover plate 2 is provided with a water injection pipe 9 with a diameter of 8CM. A filter 10 is arranged above the water injection pipe 9. The water injection pipe 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com