Comprehensive control method of grouting and drainage for high-level abscission water damage in coal mines

A comprehensive treatment and grouting technology, applied in drainage, mining equipment, earthwork drilling, etc., can solve the problems of deformation and damage of diversion holes, unstable structure of hole body, and easy damage, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be briefly described below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other implementations obtained by those of ordinary skill in the art without creative work For example, all belong to the protection scope of the present invention.

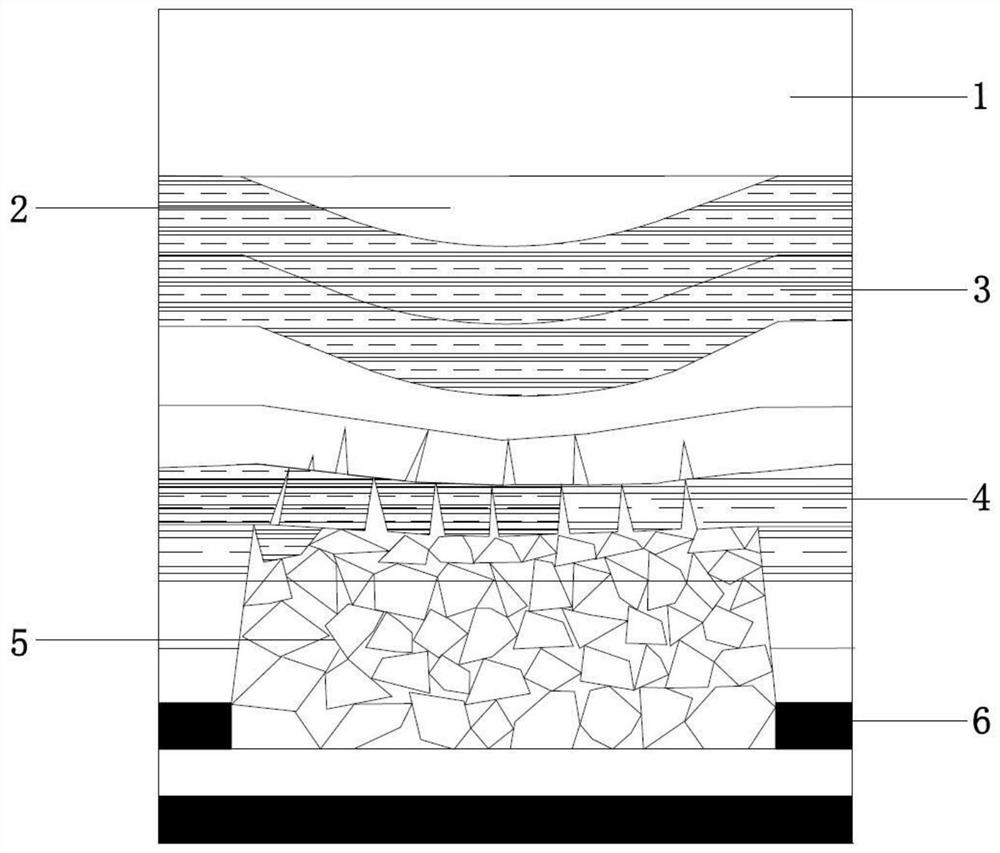

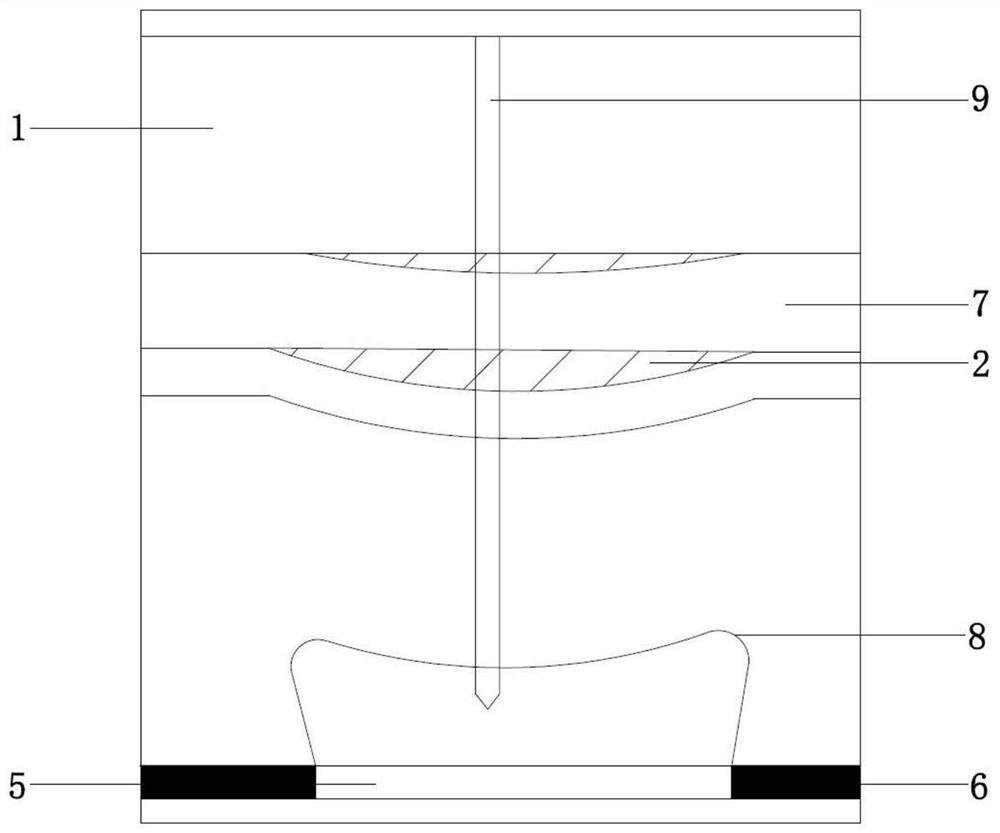

[0040] The following takes the Cuimu coal mine in Yonglong-Binchang mining area of Shaanxi as an example, combined with the attached Figure 2-4 The grouting-drainage comprehensive treatment method for high-level abscission water damage in a coal mine provided by the present invention is further described.

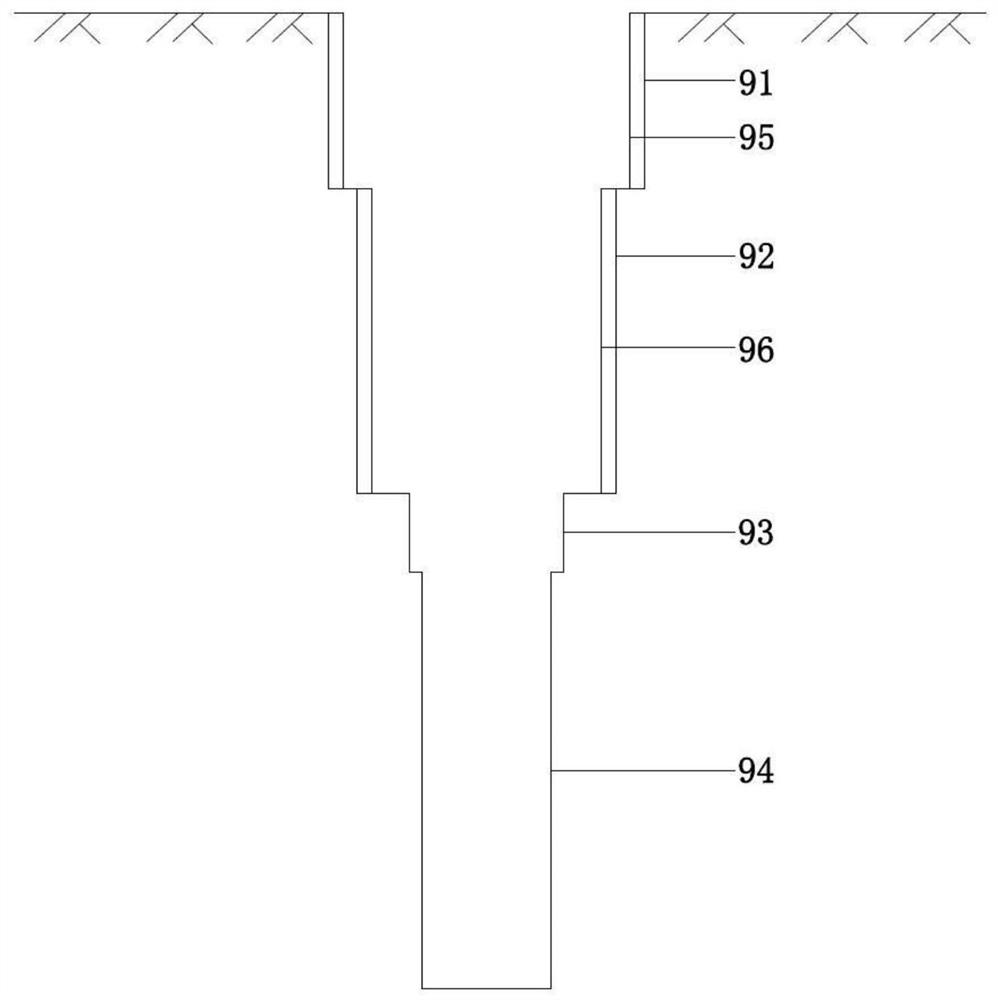

[0041] like figure 2 The shown grouting-drainage hole includes four drilling sections with decreasing diameters: the first drilling section 91 is a loose layer cementing section, including ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com