A planetary gear reducer whose output shaft can reciprocate in a straight line

A linear reciprocating, wheel reducer technology, applied in the direction of components with teeth, belts/chains/gears, transmission parts, etc., can solve the problems of adding intermediate conversion devices, increasing cost investment, etc., to shorten the transmission chain, structure The effect of compactness and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the technical solutions of the present invention, the present invention will be further described below through examples.

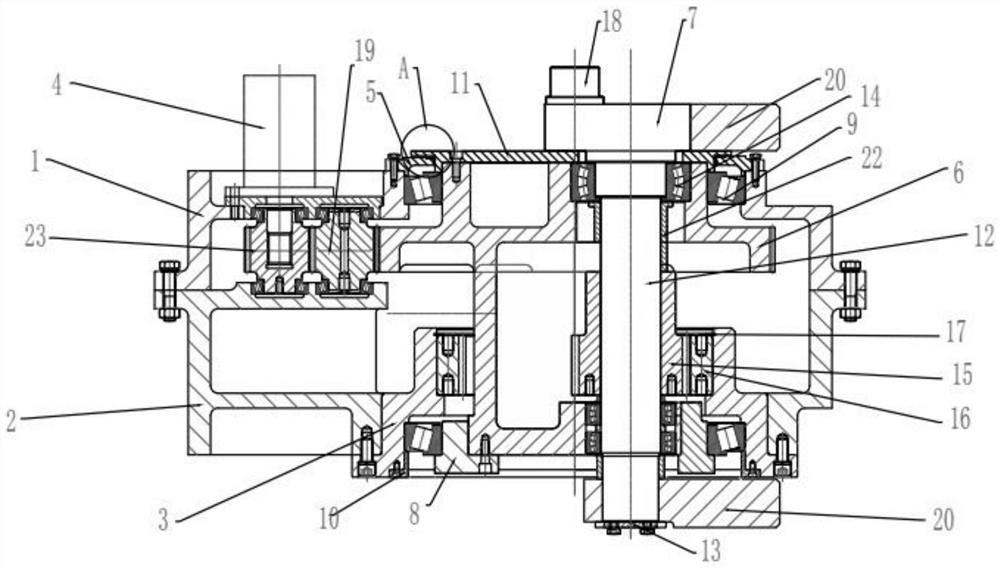

[0021] like figure 1 A planetary gear reducer with an output shaft that can travel in a straight line reciprocating includes an upper casing 1, a lower casing 2 and a base 3, and the upper casing 1, the lower casing 2 and the base 3 are sequentially and fixedly connected to each other. At the same time, an input shaft 4 is installed on the upper casing 1, a gear 23 is arranged on the input shaft 4, and the gear 23 is meshed with a gear drum 6, and the gear 23 and the gear drum 6 A speed change gear 19 is arranged therebetween to adjust the running speed of the output shaft 18. The third end cover 8 is fixedly installed on the lower end of the gear drum 6 by bolts. Between the gear drum 6 and the upper casing 1 and A tapered roller bearing 9 is arranged between the No. 3 end cover 8 and the machine base 3, and a No. 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com