Part detection mechanism based on machine vision and use method thereof

A technology of machine vision and detection mechanism, which is applied in the field of parts detection and can solve problems such as occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

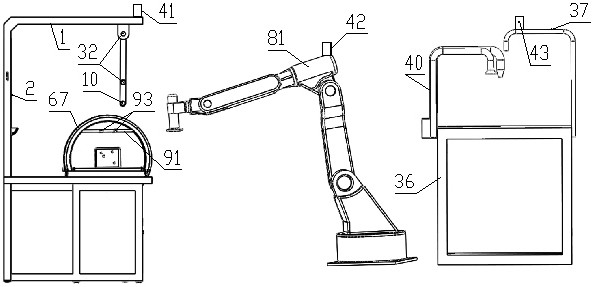

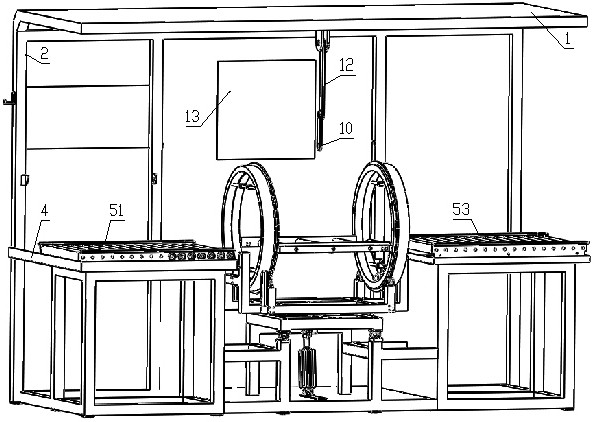

[0117] like Figure 1 to Figure 18 As shown, the part detection mechanism based on machine vision of the present invention includes a frame 2, with the overall moving direction of the detected part 31 as the downstream direction, and the frame 2 is sequentially provided with an input transmission mechanism 51, a clamping Shooting mechanism 52 and output transmission mechanism 53; The transmission surface of input transmission mechanism 51 is flush with the transmission surface of output transmission mechanism 53; The frame 2 is also provided with an electric control device 20, and the electric control device 20 is connected with a display screen 13 and an audio system. Optical alarm 19, with an image recognition module in the electric control device 20;

[0118] The clamping and shooting mechanism 52 includes a camera mechanical arm 12 hinged at the top of the frame 2 and a clamping device installed at the middle and lower part of the frame 2; the camera mechanical arm 12 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com