Method for controlling slag line erosion of submersed nozzle by using external electric field

An applied electric field and immersion technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting molten material containers, etc., can solve the problems of single casting conditions and limited improvement effect, and achieve strong universality, single casting time increase, The effect of simple process operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

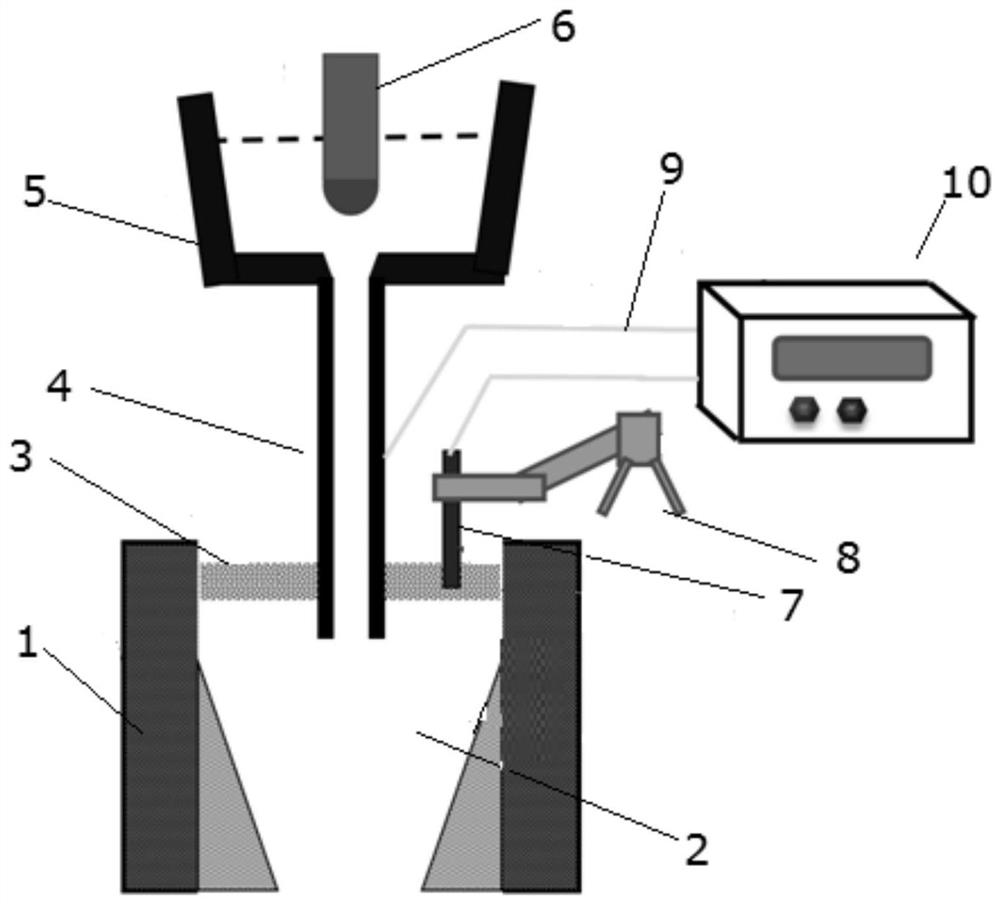

Embodiment 1

[0042] In this example, a double-strand ultra-low-carbon slab continuous casting is taken as the object. During the experiment, one nozzle is casted normally as a control group, and the other nozzle is casted by an external electric field control method as an experimental group. For the experimental group, prior to casting, the outside of the nozzle needs to be grooved in advance, and the high-temperature metal wires should be evenly wound inside the groove. The slotting position is 40 cm above the slag line of the submerged nozzle, the slot width is 1.5 cm, and the slot depth is 1.3 cm. The selected high-temperature metal wire is metal molybdenum with a high melting point, and the diameter of the wire is 1.5 mm. After that, the graphite rod used is slotted, and the high-temperature metal wire is evenly wound inside the slot. Wherein the diameter of the graphite rod is 5cm, and the length of the graphite rod is 1.4m. The slotting position is 3cm away from the top of the grap...

Embodiment 2

[0045] This embodiment still takes the continuous casting of a double-strand ultra-low carbon slab as described in Embodiment 1 as the object. During the experiment, the nozzles of the two streams are casted in a manner controlled by an external electric field as the experimental group. A comparative experiment was carried out with the contrast flow without electric field applied in Example 1. During the casting process, all the operation processes remained unchanged, except that the casting time in the original continuous casting process was increased from 6.5 hours to 8.5 hours.

[0046] During the casting process, compared with the normal casting nozzle and its nearby liquid surface, the liquid surface near the nozzle controlled by the electric field is still very stable without obvious fluctuations. After the casting is completed, the change of the slag line of the two nozzles is still not obvious. After the nozzle is cut open, it is found that the inside of the slag line o...

Embodiment 3

[0048] In this example, the continuous casting of low-carbon steel billets with one machine and eight streams in a steel factory is used as the experimental object. During the experiment, the second nozzle is used as the control group for normal casting, and the seventh nozzle at the other end is applied with an external electric field The control method was cast as the experimental group. For the experimental group, prior to casting, the outside of the nozzle needs to be grooved in advance, and the high-temperature metal wires should be evenly wound inside the groove. The slotting position is 35cm above the slag line of the submerged nozzle, the slot width is 1.5cm, and the slot depth is 1.5cm. The selected high-temperature metal wire is metal molybdenum with a high melting point, and the diameter of the wire is 1.0 mm. After that, the graphite rod used is slotted, and the high-temperature metal wire is evenly wound inside the slot. Wherein the diameter of the graphite rod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com