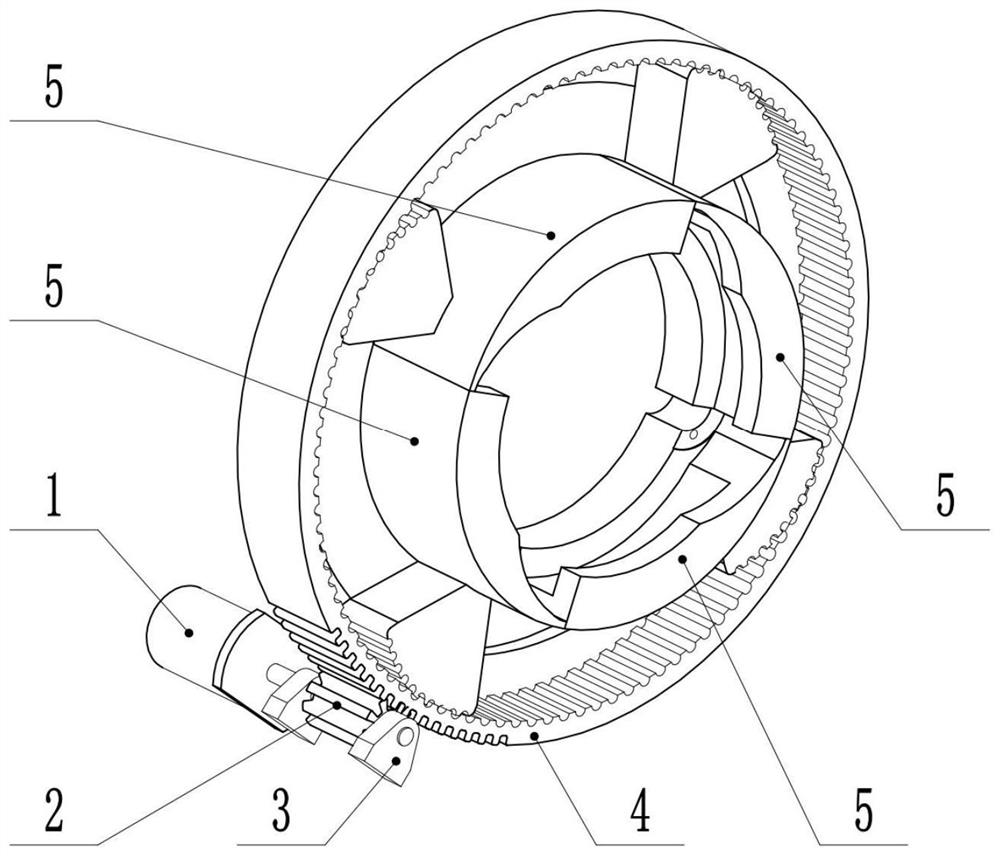

A four-piece combined shutter clamp device

A clamp and shutter technology, used in pressure vessels, gas/liquid distribution and storage, fixed-capacity gas storage tanks, etc., can solve the problems of poor support stability, unfavorable safety production, large floor space, etc., and achieve less space occupation. , Simple control, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

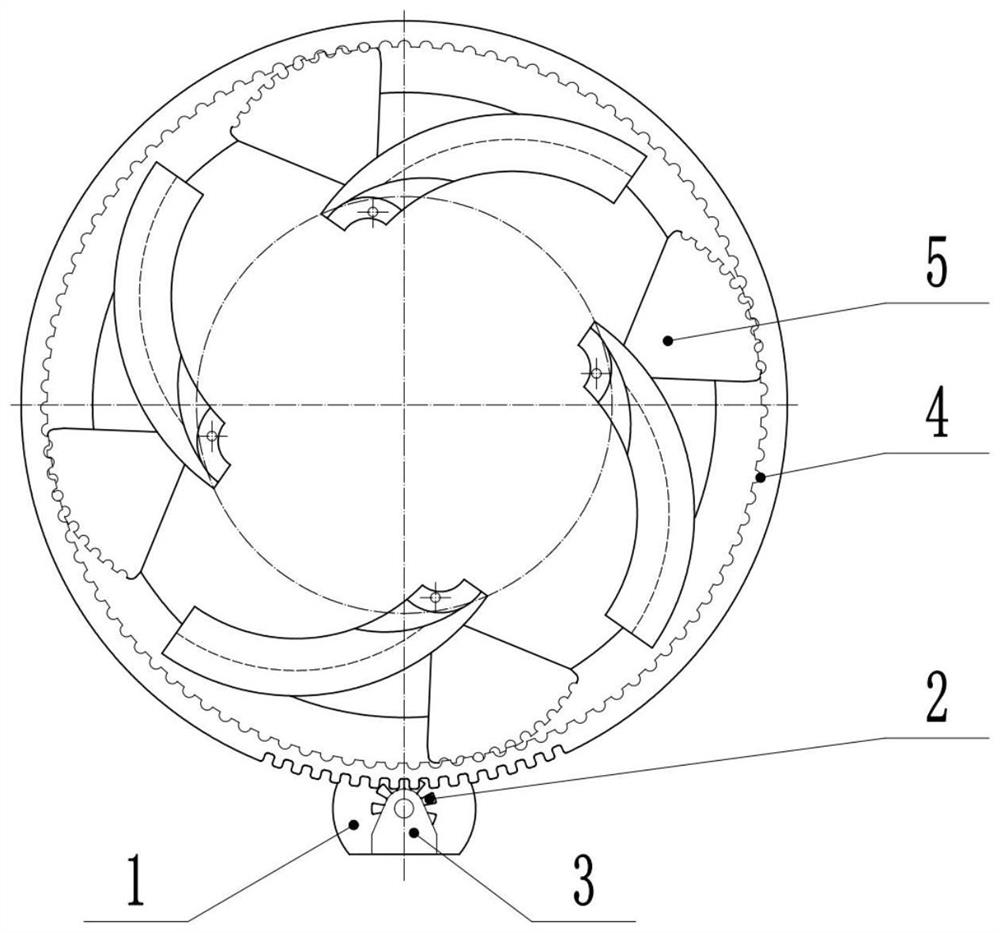

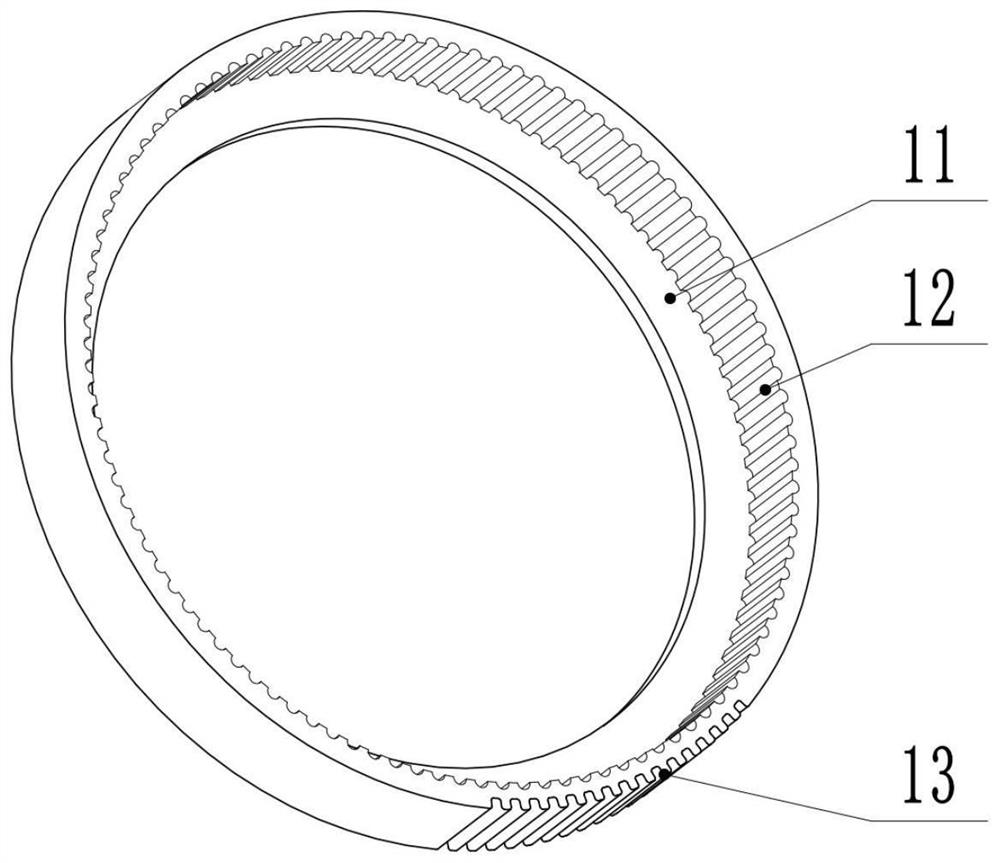

[0026] Refer to the attached figure 1 , attached figure 2 , attached Figure 4 , attached Figure 5 , attached Image 6 and attached Figure 7 :

[0027] Tank body locking process

[0028] First, align the end cap protruding edge (401) of the end cap assembly (40) with the can body mouth protruding edge (421) of the tank body device (42); then start the clamp drive motor (1) to rotate counterclockwise, and the clamp The drive gear (2) drives the clamp drive gear ring (4) to rotate clockwise, and the four shutter-type clamps (5) meshing with the clamp drive gear ring (4) surround the tank body device (42) respectively. The clamp positioning shaft (422) rotates clockwise, and the clamp groove (21) of the shutter clamp (5) connects the end cover protruding edge (401) of the end cover assembly (40) with the tank body of the tank body device (42). The protruding edge (421) of the mouth is engaged to complete the locking process of the tank.

[0029] Tank opening process

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com