Modular adjustable hoisting equipment for high-rise steel structure and construction method

A hoisting equipment and steel structure technology, used in transportation and packaging, load hoisting components, cranes, etc., can solve the problems of falling, poor hoisting work safety, easy tilting of objects, etc., to prevent electric leakage from hurting people and work. Stable and safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

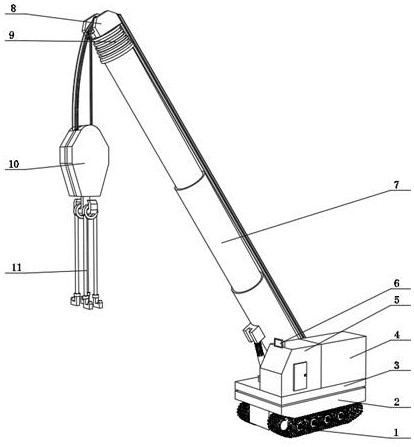

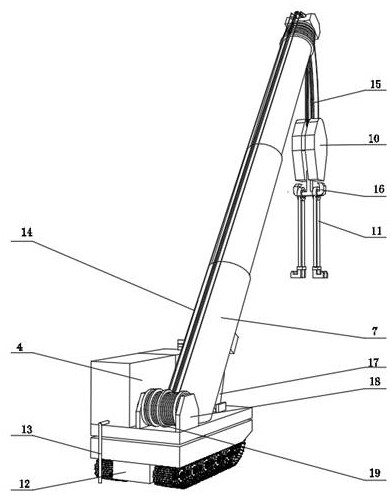

[0038] A high-rise steel structure modular adjustable hoisting equipment, such as Figure 1-6 As shown, it includes a support seat 2, the bottom outer wall of the support seat 2 is provided with two crawler belts 1, the top outer wall of the support seat 2 is fixed with a movable seat 3 through a bearing, and the top outer wall of the movable seat 3 is provided with a cab 5, driving The top outer wall of the warehouse 5 is fixed with an illuminating lamp 6 by bolts, the top of the movable seat 3 is provided with a power warehouse 4 on the side outer wall near the driving cabin 5, and the side outer wall of the power warehouse 4 is provided with a ground wire 13, and the top of the movable seat 3 One side of the outer wall is provided with an adjustment mechanism, and the outer wall of the side of the movable seat 3 close to the adjustment mechanism is provided with a winding mechanism; the power bin 4 is used to provide power support for the hoisting work, the lighting lamp 6 i...

Embodiment 2

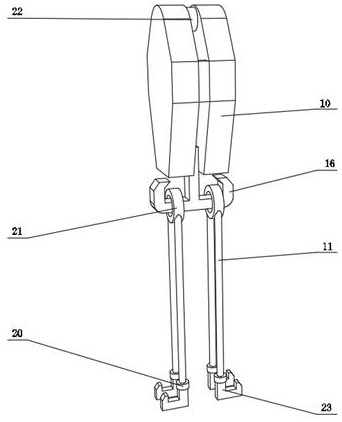

[0044] A high-rise steel structure modular adjustable hoisting equipment, such as figure 2 , 4 As shown in and 5, in order to prevent the steel wire rope 15 from breaking during hoisting, the phenomenon of falling objects from high altitude occurs; The second 32 is located in the middle of the two rewinding bins one 31, the rewinding bin two 32 has a steel wire rope, and each rewinding bin 32 is rewound with a connecting rope 14, and the rotating rod 27 is separated by the partition board two 28. Two slide rail one 25 and slide rail two 26, slide rail two 26 are positioned at the middle of two slide rail one 25, and each connecting rope 14 all contacts with slide rail one 25, and the other end of each connecting rope 14 is all connected with Movable frame 10 is connected; Be connected with movable frame 10 by connecting rope 14, when preventing steel wire rope 15 from breaking, the phenomenon of falling objects from high altitude occurs, improve the safety of its work, conne...

Embodiment 3

[0047] A construction method of modular adjustable hoisting equipment for a high-rise steel structure, comprising the following steps:

[0048] S1: First of all, carry out a test hoist before hoisting work, check the force of all machines and tools, confirm that everything is normal, and proceed to formal hoisting;

[0049] S2: Subsequently, the hydraulic pump 12 is connected to the hydraulic rod 7 to form a pipeline, so that the hydraulic pump 12 drives the hydraulic rod 7 to expand and contract through the forward and reverse rotation of the gear, and is connected to the hydraulic rod 7 through the cylinder 17, so that the height and The angle can be adjusted;

[0050] S3: At the same time, the object is fixed on the object through the hook 23, and the object is hoisted at multiple points;

[0051] S4: Immediately afterwards, start the motor 30, so that the motor 30 drives the reel to rotate, thereby rewinding the wire rope 15, so that the movable frame 10 moves up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com