High-temperature-resistant adhesive tape

A technology of high temperature resistance and adhesive tape, which is applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. It can solve the problems of easy breakage of the tape base material, easy accumulation of heat in the tape, and decrease in adhesive viscosity. Achieve the effect of not easy to wear, not easy to reduce viscosity, not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

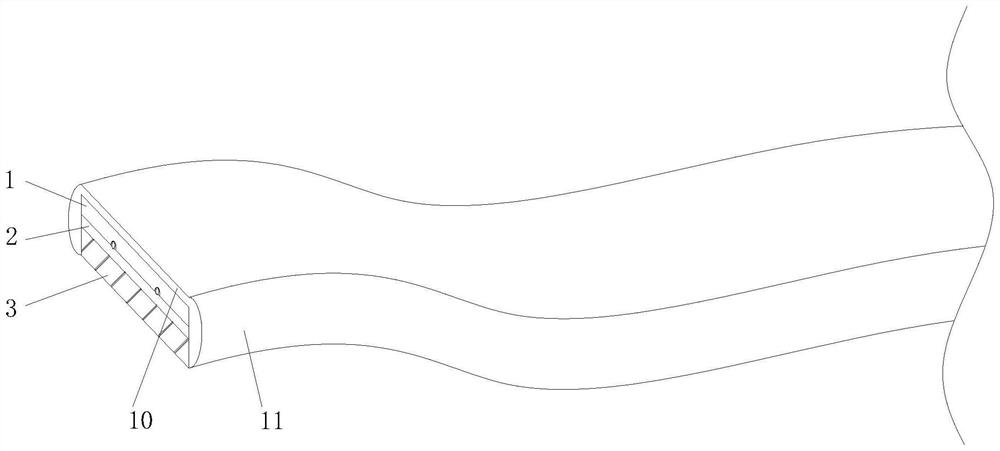

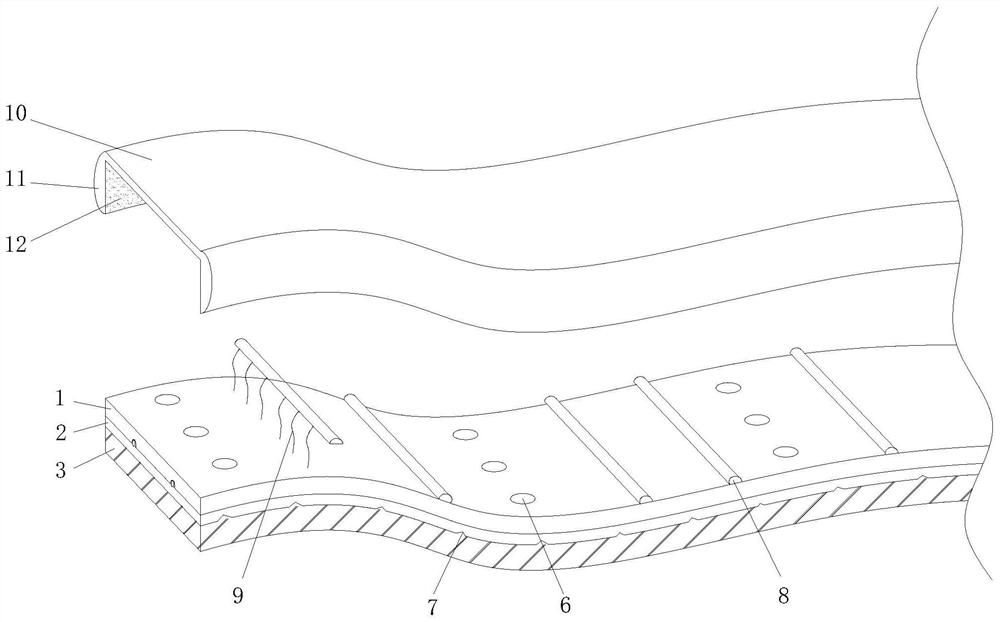

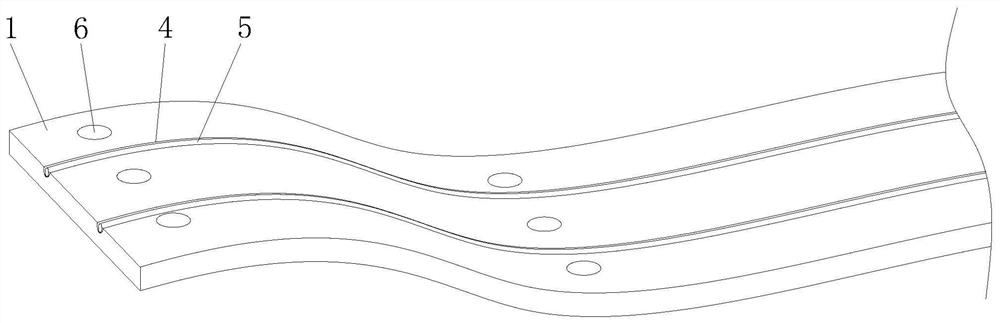

[0026] according to figure 1 , 2 , 3, the present embodiment proposes a high-temperature-resistant adhesive tape, including an anti-oxidation layer 1, an aluminum foil film layer 2 and a high-temperature-resistant soft rubber layer 3, and the aluminum foil film layer 2 is bonded to the high-temperature-resistant soft rubber layer 3 Above, the anti-oxidation layer 1 is arranged on the top of the aluminum foil film layer 2, the bottom of the anti-oxidation layer 1 is provided with an embedded groove 4, and the inside of the embedded groove 4 is provided with a heat-resistant fiber 5, the anti-oxidation Layer 1 is provided with cooling holes 6, and multiple groups of cooling holes 6 are provided, the bottom of the aluminum foil film layer 2 is provided with filling grooves 7, and the top of the high temperature resistant soft rubber layer 3 is filled into the filling grooves 7; The oxide layer 1 and the aluminum foil film layer 2 are used as the base material. The aluminum foil ...

Embodiment 2

[0037] according to figure 1 , 2 , 3, the present embodiment proposes a high-temperature-resistant adhesive tape, including an anti-oxidation layer 1, an aluminum foil film layer 2 and a high-temperature-resistant soft rubber layer 3, and the aluminum foil film layer 2 is bonded to the high-temperature-resistant soft rubber layer 3 Above, the anti-oxidation layer 1 is arranged on the top of the aluminum foil film layer 2, the bottom of the anti-oxidation layer 1 is provided with an embedded groove 4, and the inside of the embedded groove 4 is provided with a heat-resistant fiber 5, the anti-oxidation Layer 1 is provided with heat dissipation holes 6, and multiple groups of heat dissipation holes 6 are provided. The bottom of the aluminum foil film layer 2 is provided with a filling groove 7, and the top of the high temperature resistant soft rubber layer 3 is filled into the filling groove 7; The oxide layer 1 and the aluminum foil film layer 2 are used as the base material. ...

Embodiment 3

[0048] according to figure 1 , 2 , 3, the present embodiment proposes a high-temperature-resistant adhesive tape, including an anti-oxidation layer 1, an aluminum foil film layer 2 and a high-temperature-resistant soft rubber layer 3, and the aluminum foil film layer 2 is bonded to the high-temperature-resistant soft rubber layer 3 Above, the anti-oxidation layer 1 is arranged on the top of the aluminum foil film layer 2, the bottom of the anti-oxidation layer 1 is provided with an embedded groove 4, and the inside of the embedded groove 4 is provided with a heat-resistant fiber 5, the anti-oxidation Layer 1 is provided with cooling holes 6, and multiple groups of cooling holes 6 are provided, the bottom of the aluminum foil film layer 2 is provided with filling grooves 7, and the top of the high temperature resistant soft rubber layer 3 is filled into the filling grooves 7; The oxide layer 1 and the aluminum foil film layer 2 are used as the base material. The aluminum foil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap