Highland barley yeast as well as preparation method and application thereof

A highland barley and Daqu technology, applied in the field of highland barley Daqu and its preparation, can solve the problems of low starch utilization rate, dense koji, low yield of wine, etc., and achieve the effects of promoting normal fermentation, increasing air permeability, and improving liquefaction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of highland barley Daqu for improving the yield of highland barley wine of the present invention comprises the following steps:

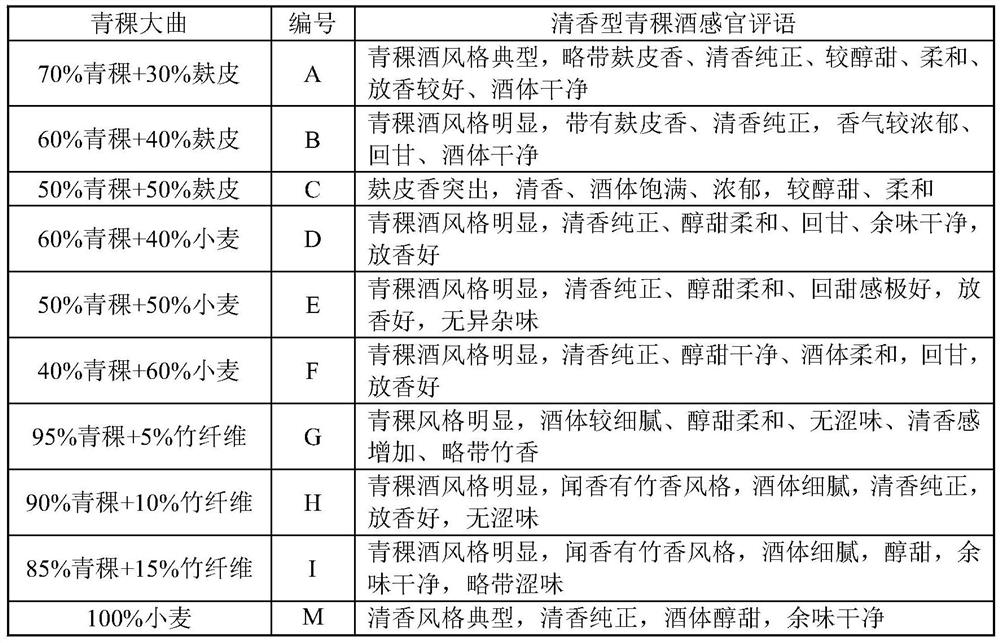

[0030] (1) Highland barley is the main raw material, with bran, wheat or bamboo fiber as auxiliary materials;

[0031] Among them, the highland barley grains are full, rich in starch 62-70%, containing 12-15% of protein and 1-5% of fat; the wheat grains are full, rich in starch 68-75%, containing 8-11% of protein and 1% of fat. ~5%; the bran is fresh and delicate, rich in starch 50-58%, containing 14-16% protein and 3-5% fat; bamboo fiber is the bamboo fiber after crushing fresh bamboo;

[0032] (2) Add 3 to 8% of water at 55 to 95°C to highland barley and wheat respectively to moisten the grain. After mixing evenly, moisten the grain for 2 to 4 hours and grind it with a roller mill. 30-60%; control the length of bamboo fiber at 1-5mm;

[0033] (3) The crushed highland barley is mixed with the crushed wheat or bran or...

Embodiment 1

[0044] The preparation of embodiment 1 highland barley Daqu

[0045] Raw materials: commercially available highland barley, full grain, starch content 65%, protein content 12.35%, fat content 2.10%; commercially available wheat, full grain, starch content 70.14%, protein content 10%, fat content 1.8%; commercially available Bran, fresh and delicate, with a starch content of 53.14%, a protein content of 13.60%, and a fat content of 2.88%. The selected bamboo fiber is bamboo fiber after crushing fresh bamboo, and the length is 1-5mm. Because wheat is the most commonly used raw material for Daqu, this application uses traditional wheat koji as a standard koji medicine and a control to verify the effectiveness of the fermentation process.

[0046] Fermentation process:

[0047] (1) Raw material crushing: add 6% water at 65° C. to the highland barley and wheat respectively, mix evenly, moisten the grain for 2.5 hours, and grind it with a roller mill.

[0048] (2) Ingredients: th...

Embodiment 2

[0055] Example 2 Enzyme Activity Analysis of Finished Highland Barley Daqu

[0056] (1) Enzyme activity indicators: fermentation power, saccharification power, liquefaction power, esterification power, acid protease activity;

[0057] Fermentation power is one of the important indicators to measure the ability of Daqu to produce wine. Saccharification power refers to the ability of starch in Daqu to be hydrolyzed into reducing sugar. Esterification power is an important indicator to reflect the ability of Daqu to produce ester. The activity of acid protease can reflect the hydrolysis of protein in Daqu. The ability to generate amino acids, amino acids can not only provide nitrogen sources for the growth of microorganisms, but also promote the production of various aroma substances in Daqu.

[0058] (2) Determination method: refer to the relevant steps in the light industry standard QB / T4257-2011 "Universal Daqu Analysis Method".

[0059] The liquefaction power is the number o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com