A kind of aluminum alloy window frame grouting reinforcement structure and construction method thereof

A technology of grouting reinforcement and aluminum alloy, which is applied in the direction of frame fixing, etc., can solve the problems of poor structural strength, poor connection strength, and poor compactness of the window frame, and achieve the effect of increasing the bonding area, improving the flatness, and improving the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

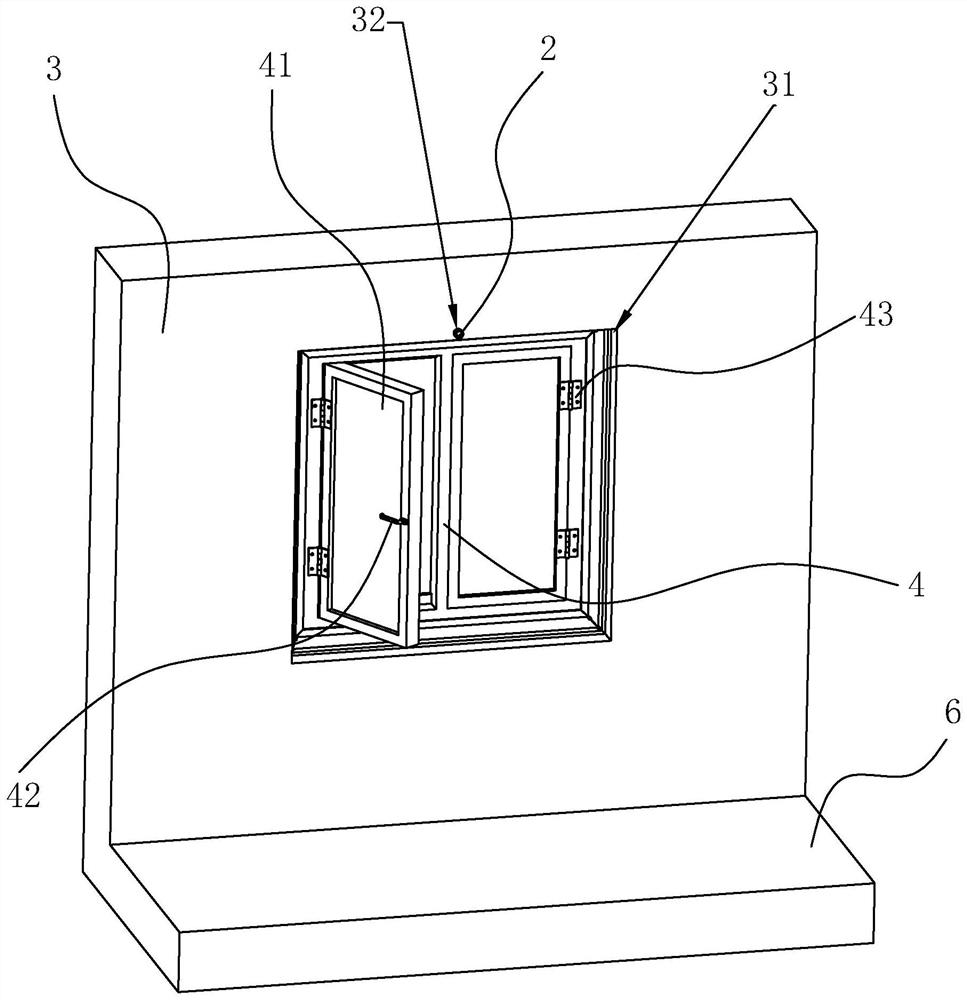

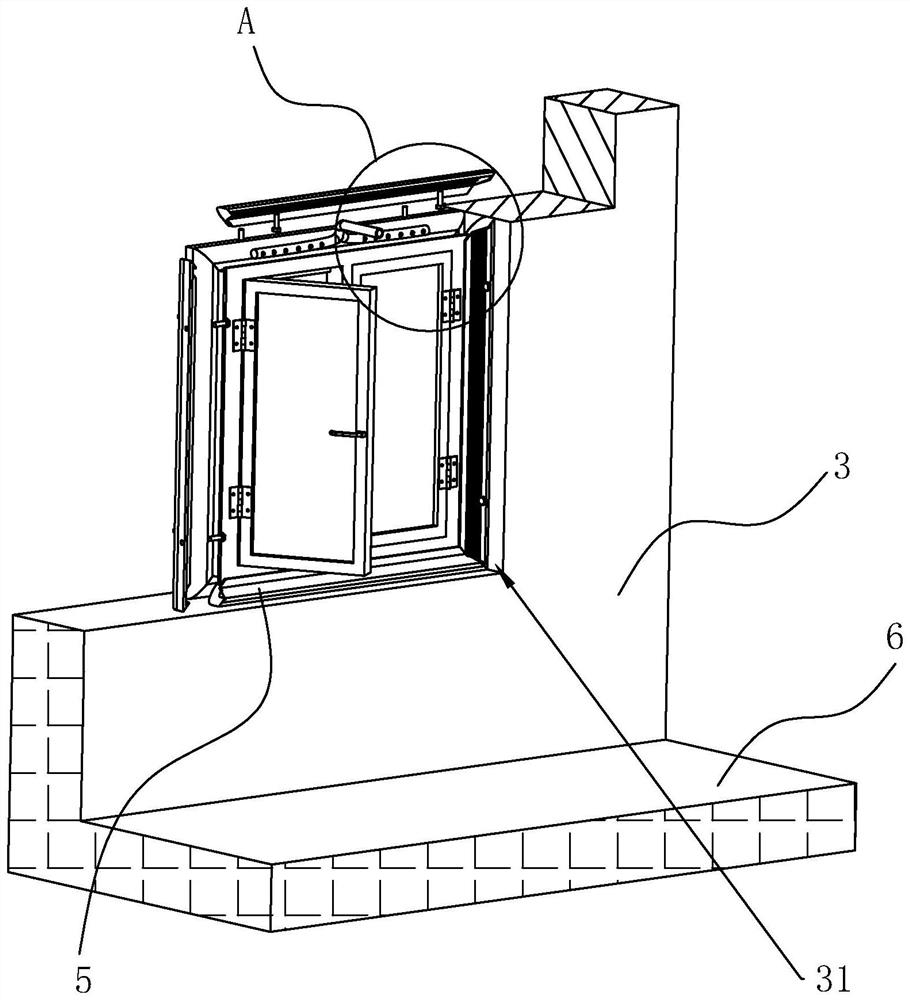

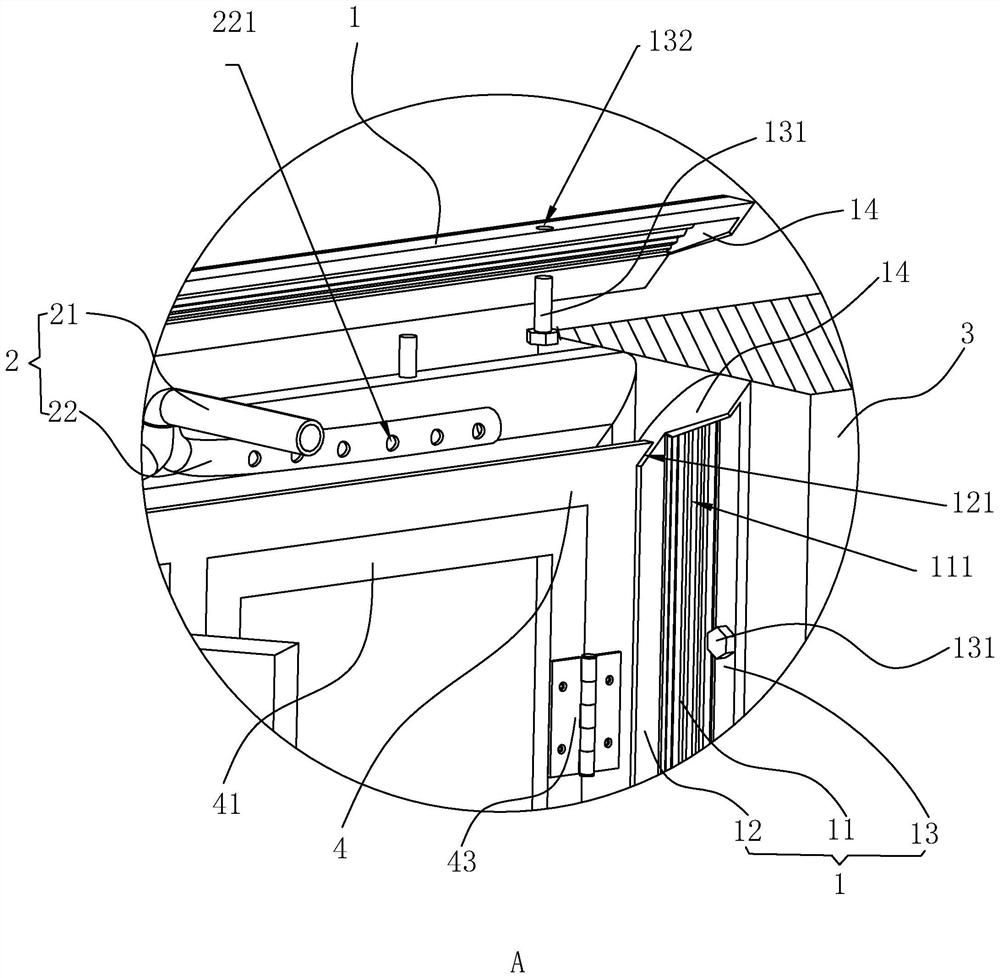

[0038] refer to figure 1 , the ground 6 is set horizontally, the ground 6 is built with a vertical wall 3, the vertical wall surface of the wall 3 is concavely provided with a square installation opening 31, and the window frame 4 is installed inside the installation opening 31, The outline of the window frame 4 is matched with the shape of the installation opening 31. The screws 131 on the vertical borders on both sides of the window frame 4 are connected with two sets of hinges 43 distributed up and down. Hingedly installed, the window 41 is equipped with a handle 42 on one side of the vertical frame away from its hinge axis. The wall 3 at the uppermost horizontal frame position of the window frame 4 is concavely provided with a grouting port 32, and the grouting port 32 is located in the middle of the width direction of the window frame 4. The grouting port 32 includes a horizontal section and a vertical end, and the horizontal section It is the inlet part of the grouting ...

Embodiment 2

[0044] A construction method of aluminum alloy window frame grouting reinforcement structure, the specific construction scheme is:

[0045] a. the window frame 4 is prefabricated according to the size of the installation opening 31; The inner wall above the level is connected; the main pipe 21 of the grouting pipe 2 runs through the grouting port 32, and one end of the main pipe 21 extends out of the entrance of the grouting port 32;

[0046] b. Insert the aluminum alloy window frame 4 into the installation port 31 by means of manpower or hoisting equipment, so that two sets of auxiliary pipes 22 are laid on the horizontal upper end of the window frame 4; each set of guard plates 1 is installed, in order according to the horizontal lower end, The vertical position on both sides and the horizontal upper end are carried out sequentially, insert the notch 121 on each group of guard plates 1 into the vertical edge of the window frame 4, and make the second horizontal section 13 ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com