Suction fan

A suction fan and wind pressure technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as inconvenient operation and reduced work efficiency, and achieve the effect of shortening response time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following exemplary embodiments and descriptions are only used to explain the present invention, not as a limitation to the present invention, and, in the case of no conflict, the embodiments in the application and the features in the embodiments can be combined with each other .

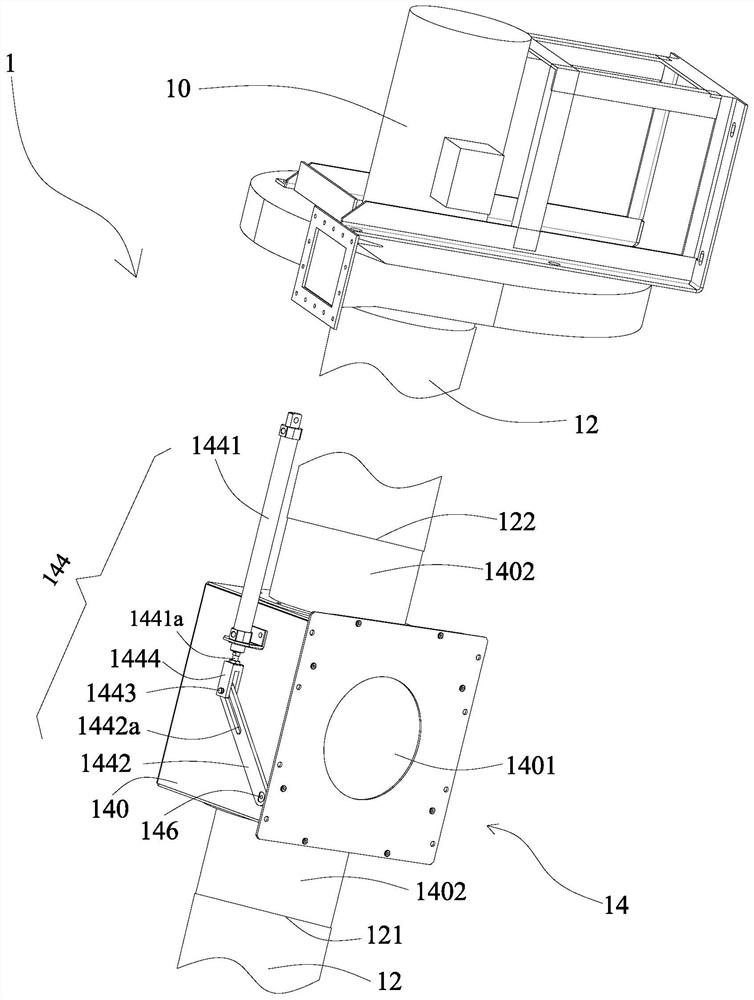

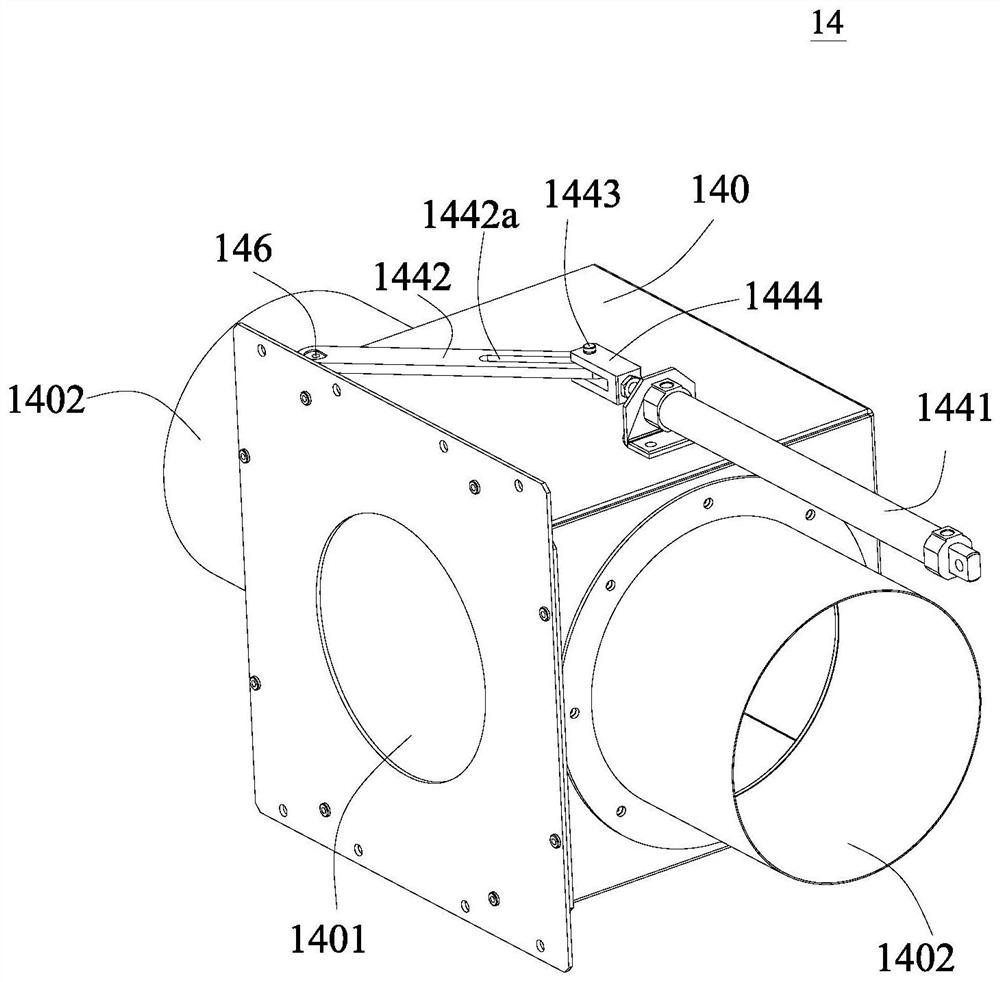

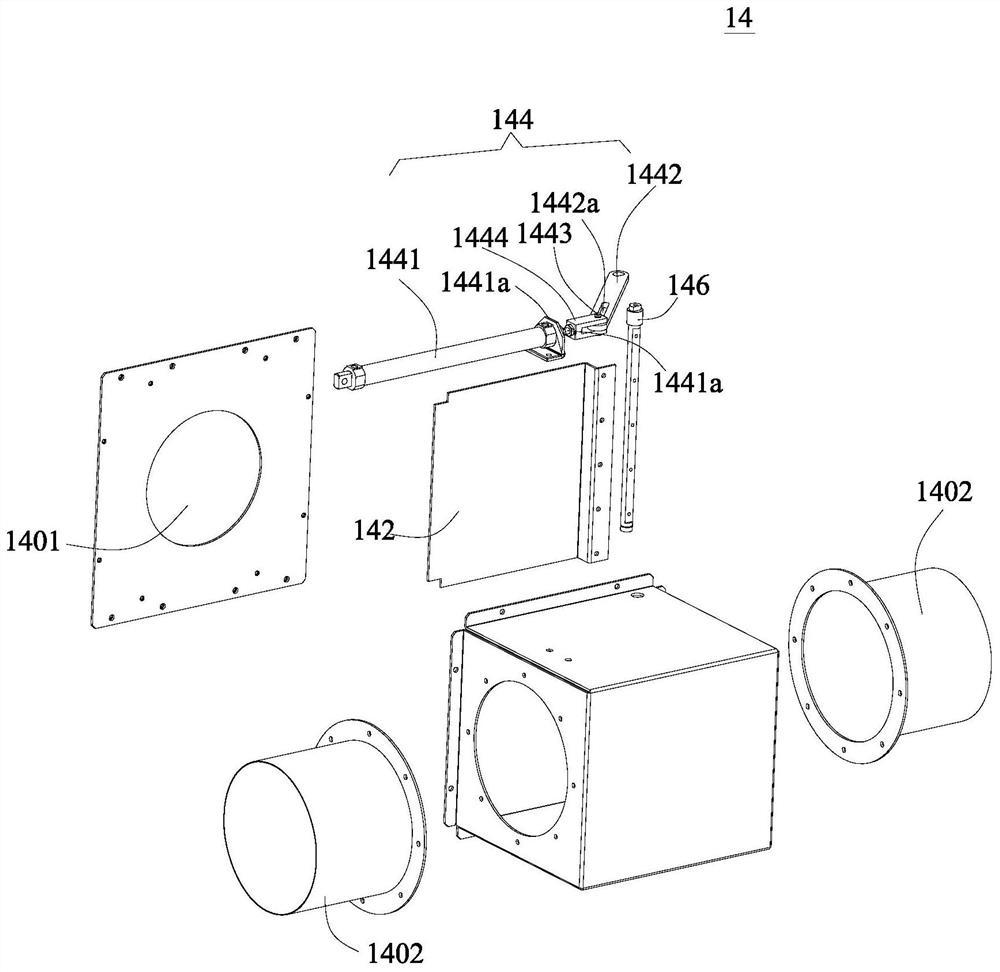

[0023] Such as Figure 1-Figure 7 As shown, an optional embodiment of the present invention provides a suction fan 1, including a suction assembly 10 and a suction duct 12 connected to the suction assembly 10, and the suction fan 1 also includes a suction pipe connected to the suction assembly 10. The air discharge assembly 14 in the pipeline 12, the air discharge assembly 14 includes two ends respectively connected to the upstream end 121 and the downstream end 122 of the suction pipe 12 and a wind pressure outlet 1401 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com