High-speed sealed bearing testing machine

A technology for sealing bearings and testing machines, which is used in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problem that the bearing cannot be tested with axial and radial loads, and the operation of high-speed bearings cannot be well simulated. Working conditions, affecting the detection efficiency, the service life of the bearing to be tested, etc., to achieve the effect of convenient comparison, convenient implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

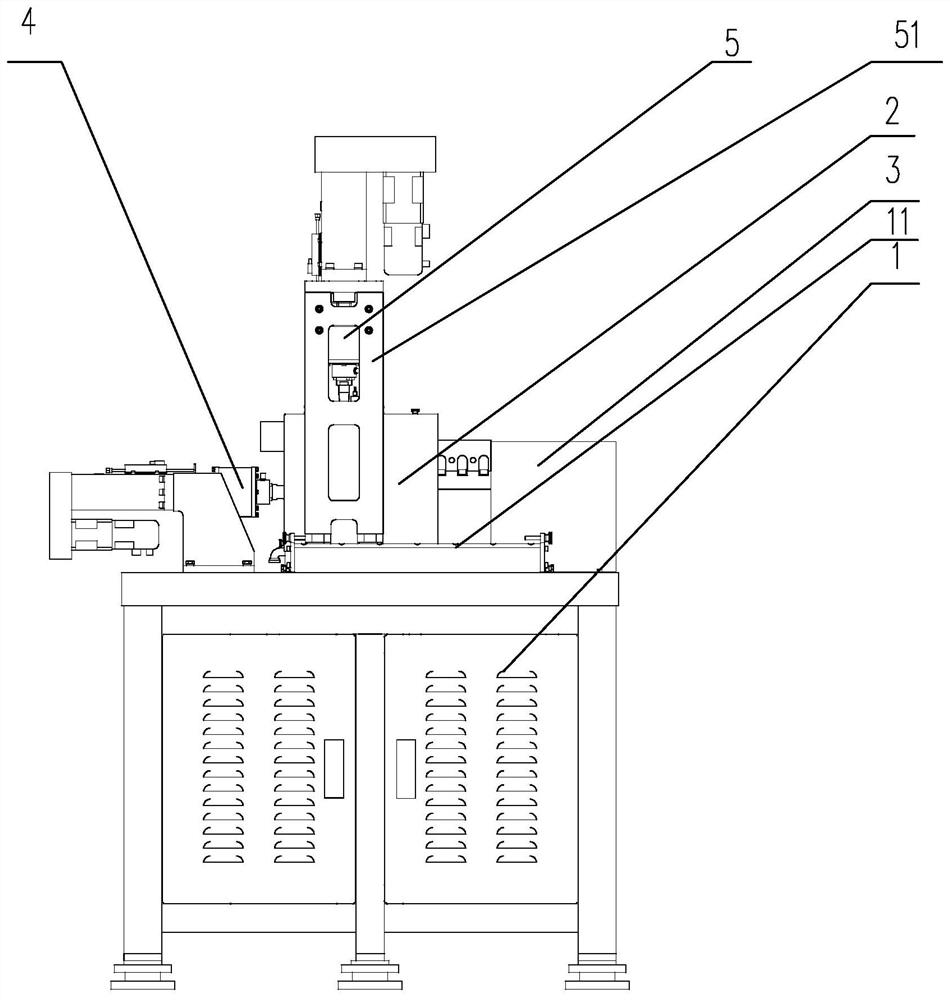

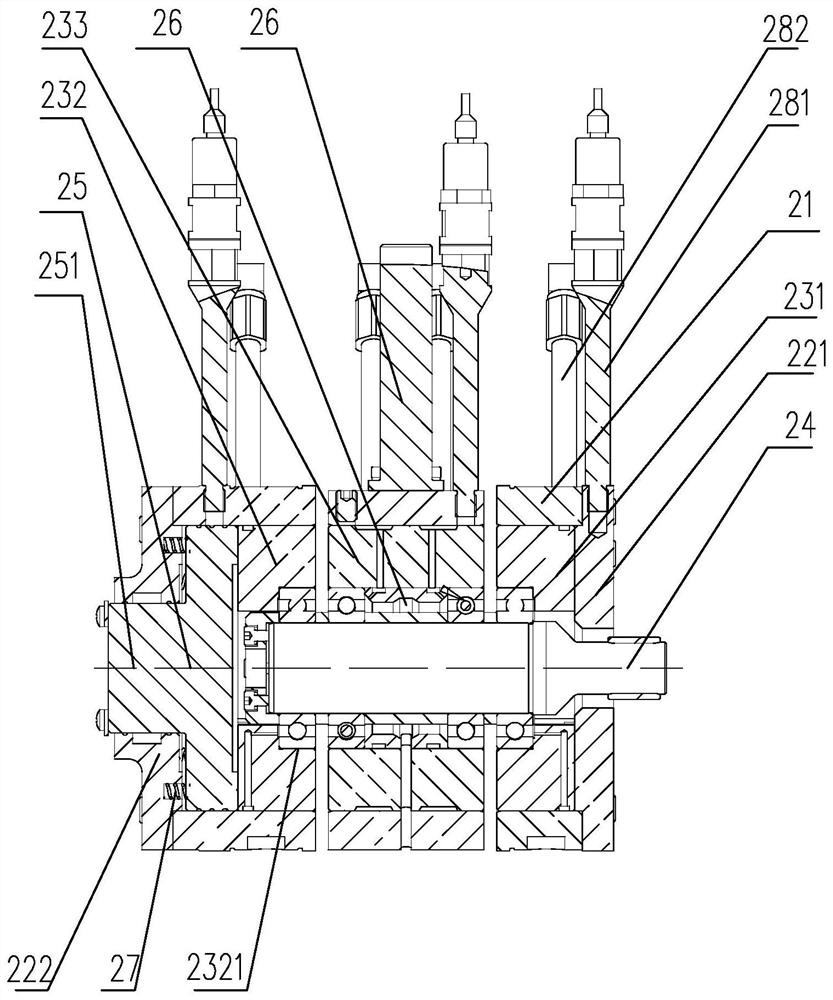

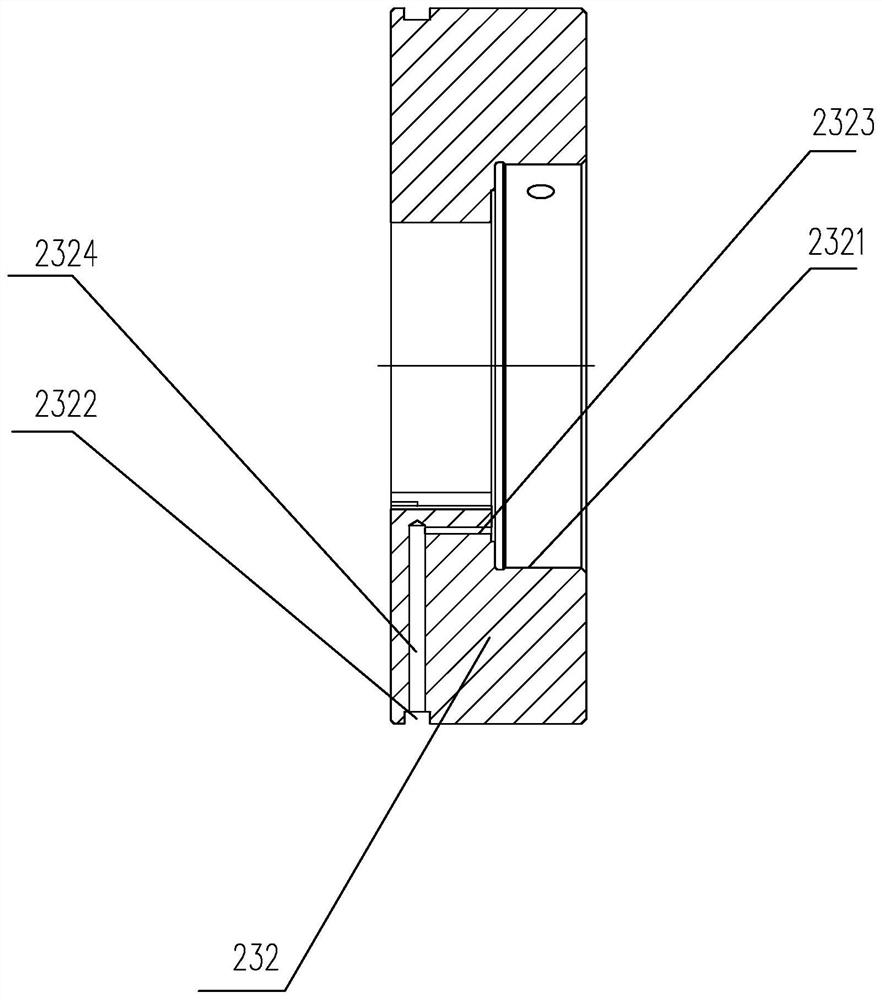

[0031] Examples of high-speed sealed bearing testing machine of the present invention Figure 1 to Figure 7Shown: includes a bracket 1, the bracket 1 is provided with a test bench 2, one side of the test bench 2 is provided with a rotating drive member 3, and the other side is provided with an axial loading device 4, and the test bench 2 is provided with A radial loading device 5 is also slidably provided, and the test stand 2 includes a test stand 21, a mandrel 24, an axial top plate 25, a first end cover 221 and a second end cover 222, and the test stand 21 is fixed to the support 1 connection, the first end cap 221 and the second end cap 222 are respectively arranged at the two ends of the test base 21 to form the closure of the two ends of the test base 21, and the mandrel 24 is rotatably arranged on the test base 21 and passes through the first end cover 221 It is provided that one end of the mandrel 24 passing through the first end cover 221 is in transmission connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com