Novel secondary structure pre-embedded electrical piping fixing clamp and installation method thereof

A secondary structure and fixed card technology, which is applied in the field of architectural decoration engineering, can solve problems such as the inability to accurately ensure the thickness of the protective layer, and achieve the effect of avoiding shaking and ensuring that the pipe is stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

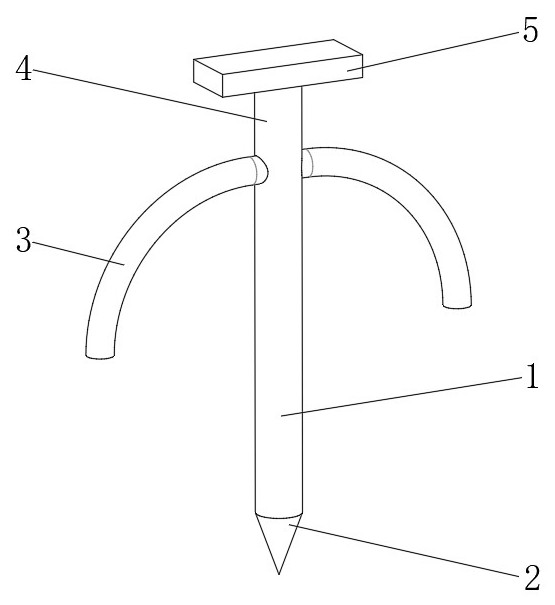

[0051] A new type of secondary structure pre-embedded electrical piping fixing clip, such as figure 1 As shown, it includes a staple 1, the bottom of the staple 1 is integrally provided with a nail head 2, the top outer wall of the staple 1 is integrally provided with a connecting column 4, the top outer wall of the connecting column 4 is integrally provided with a hammer receiving part 5, and the staple 1 is provided with a fixing structure for fixing electrical pipes. The fixing structure includes two clip fixing parts 3, and the two clip fixing parts 3 are integrally arranged on the outer walls of both sides of the clip 1. The two clip fixing parts 3 are symmetrical arcs. Shaped structure, the distance from the top of the clip fixing part 3 to the top outer wall of the hammered part 5 is 1.5cm or 3cm.

[0052] When this embodiment is in use, by providing structures such as the staple 1 and the clip fixing part 3, when installing a double-tube type electrical pipe, the stapl...

Embodiment 2

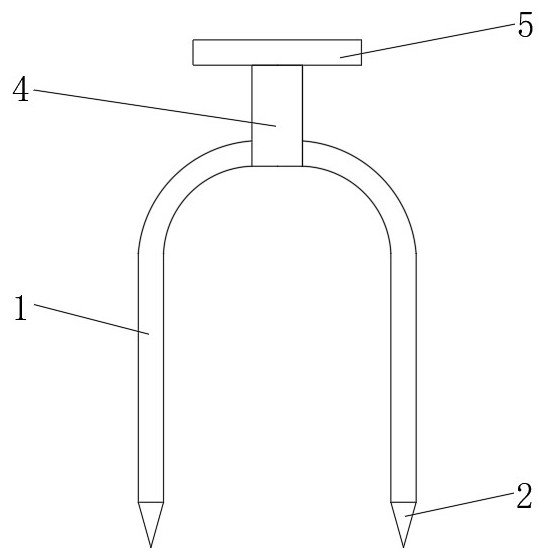

[0054] A new type of secondary structure pre-embedded electrical piping fixing clip, such as figure 2 As shown, in order to facilitate the installation of single-tube electrical piping; this embodiment makes the following improvements on the basis of embodiment 1: replace the staple 1 with an inverted U-shaped structure, and the connecting column 4 is integrally arranged on the top of the staple 1 In the middle part, there are two nail heads 2, which are integrally arranged at both ends of the bottom of the staple 1; the length of the connecting column 4 plus the thickness of the hammered part 5 is 1.5 cm or 3 cm.

[0055] When this embodiment is in use, by setting the staple 1 with an inverted U-shaped structure, when installing a single-pipe type electrical pipe, the staple 1 can be used to be stuck on both sides of the electrical pipe, and the hammered part 5 can be knocked to make the staple 1 By embedding the nail head 2 into the wall, the staple 1 is used to limit and f...

Embodiment 3

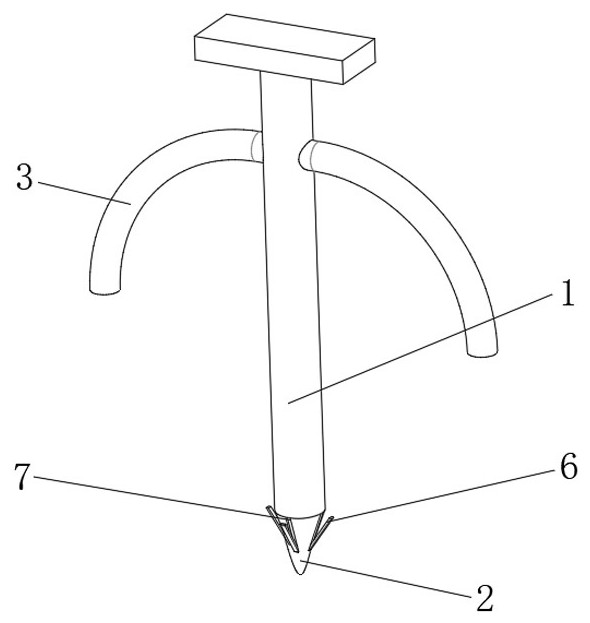

[0057] A new type of secondary structure pre-embedded electrical piping fixing clip, such as image 3 As shown, in order to improve the firmness of the installation; this embodiment makes the following improvements on the basis of Embodiment 1: the side wall of the nail head 2 is provided with accommodating grooves 7 evenly distributed around the circumference, and the inner wall of the bottom of the accommodating groove 7 is welded with spring teeth 6, and The top ends of the teeth 6 extend outwards along the vertical upward direction.

[0058] When this embodiment is in use, by setting the elastic tooth 6 and the receiving groove 7, during the process of hitting the hammer part 5, the elastic tooth 6 is received inside the accommodation groove 7 due to resistance, and after being installed and fixed, one end of the elastic tooth 6 is deformed. Under the action of force, it can achieve close contact and fixation with the wall. When the staple 1 tends to loosen, the elastic te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com