A nano-metal-assisted directional electroplating and electrolysis circuit forming and repairing method

A nano-metal and repair method technology, which is applied in printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve problems such as complex process, and achieve the effect of promoting diffusion, promoting diffusion and transport, and maintaining ion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

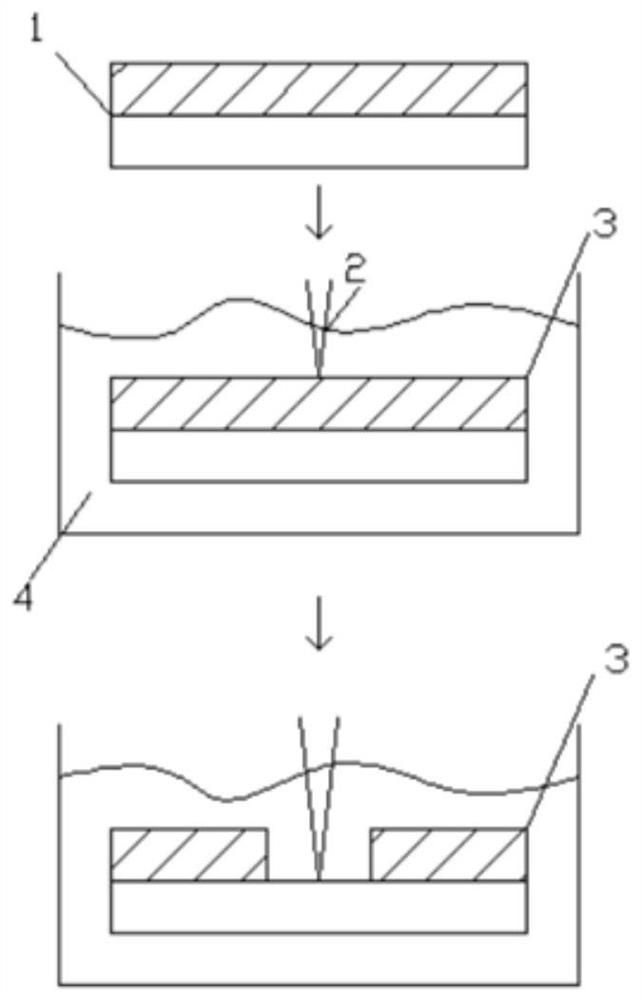

[0066] see figure 1 , for the 10×10mm copper circuit board 1 to be formed, the following steps are used for forming:

[0067] 1) Determine the area 3 to be formed on the copper circuit board according to the process requirements.

[0068] 2) Use the direct contact method of the energized wire to energize the copper circuit board 1, so that the copper circuit board 1 is positively charged as a whole.

[0069] 3) Place the energized copper circuit board 1 in the copper sulfate solution 4 with a mass fraction of 10%, so that the copper sulfate solution 4 completely immerses the copper circuit board 1 .

[0070] 4) Use a highly conductive metal probe 2 with a diameter of 50 μm to move to a distance of 100 μm directly above the area to be repaired on the circuit board 1, and apply negative electricity to the metal probe 2 to make the gap between the circuit board 1 and the probe 2 A potential difference of 3V is generated, and a local current is formed in the area of the circui...

Embodiment 2

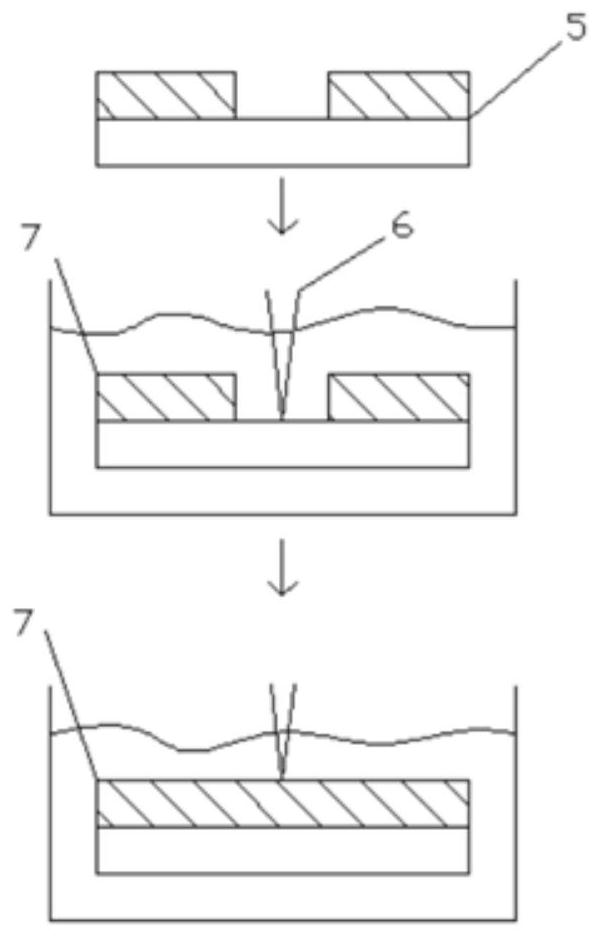

[0072] see figure 2 , for the rewiring layer copper circuit board 5 of 9x9mm to be repaired, the following steps are used to repair:

[0073] 1) Determine the position of the defect on the copper circuit board 5 by automatic optical detection technology, and determine the repair area 7 .

[0074] 2) Use the direct contact method of the energized wire to energize the copper circuit board 5, so that the copper circuit board 5 is negatively charged as a whole.

[0075] 3) Place the energized copper circuit board 5 in a copper chloride solution with a mass fraction of 7%, so that the solution completely immerses the copper circuit board 5 .

[0076] 4) Use a highly conductive metal probe 6 with a diameter of 30 μm to move to a distance of 100 μm directly above the area to be repaired on the circuit board 5, and apply positive electricity to the metal probe 6 to make the contact between the circuit board 5 and the probe 6 A potential difference of 5V is generated between them, a...

Embodiment 3

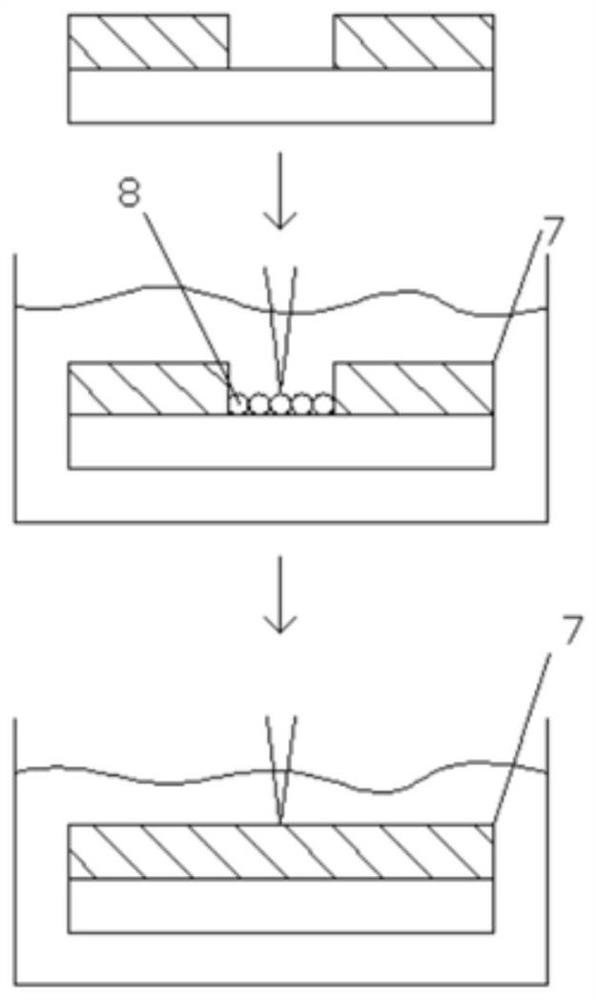

[0078] Embodiment 3 is substantially the same as Embodiment 2, except that Embodiment 3 also includes the following steps between steps 1) and 2):

[0079] Copper nanoparticles 8 coated with polyvinylpyrrolidone with a particle diameter of 50nm were added to ethylene glycol to form a copper paste with a solid content of 80% and sent to the defect position of the copper circuit board 7 through the drip nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com