Adjustable stent with buckle structure

An adjustable, body-based technology, which is applied to human body tubular structure devices, stents, medical science, etc., can solve the problems of easy formation of thrombus, vessel wall damage, thrombus formation, etc., to avoid stuck or locked, save materials, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

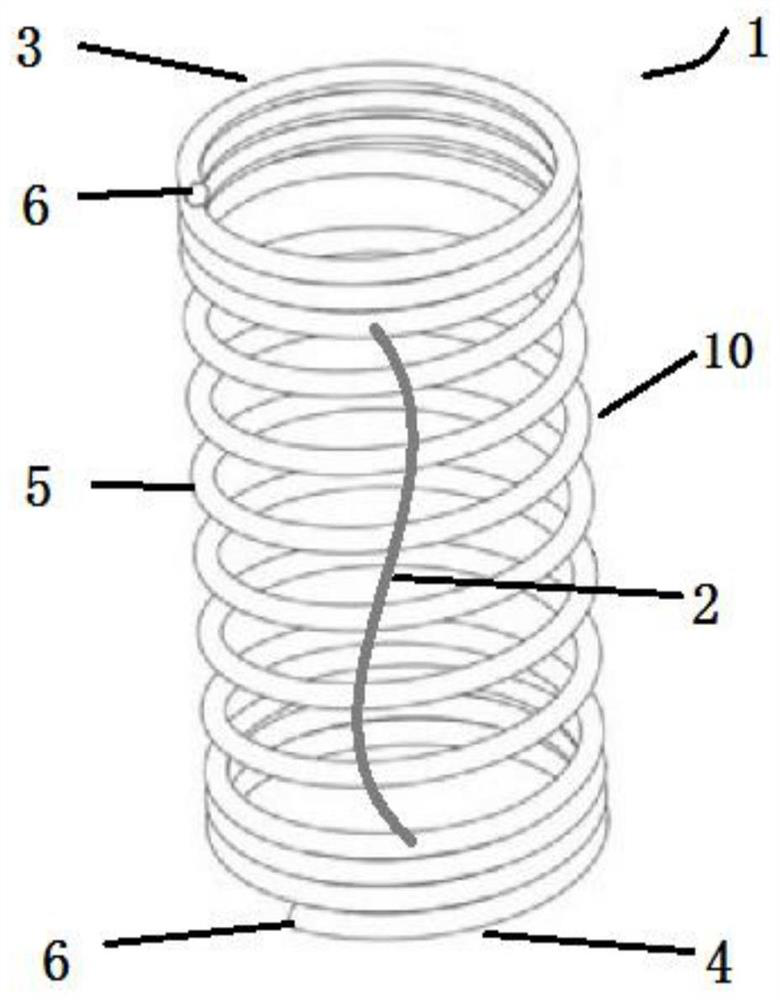

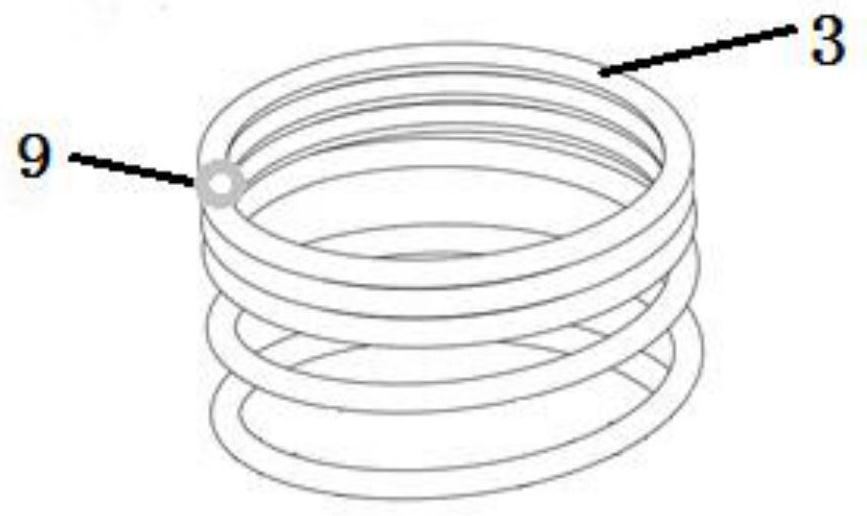

[0025] Such as Figure 1-3 As shown, an adjustable bracket with a buckle structure includes a bracket body 10 with a cavity, and elastic buffer ribs 2 arranged on the bracket body 10. The bracket body 10 is made of a single metal wire or a plurality of Composite metal wire is helically wound, such as elastic metal wire wound around a mold and shaped, it can also be 3D printed from elastic polymer materials, and has two configurations of axial compression and expansion. The buffer ribs 2 are elongated and S-shaped, and are fixed on the outer surface or inner surface of the bracket body 10 by spot welding or bonding. When the bracket is compressed or expanded axially, the buffer ribs 2 are correspondingly Compression or expansion, the buffer ribs 2 are two and symmetrically arranged along the central axis of the bracket, one end of each buffer rib 2 is attached to the first end 3 of the bracket body, and the other end is attached to the second end 4 of the bracket body .

[00...

Embodiment 2

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, each buffer rib 2 is formed into an integrated structure by connecting two elastic material wires end-to-end.

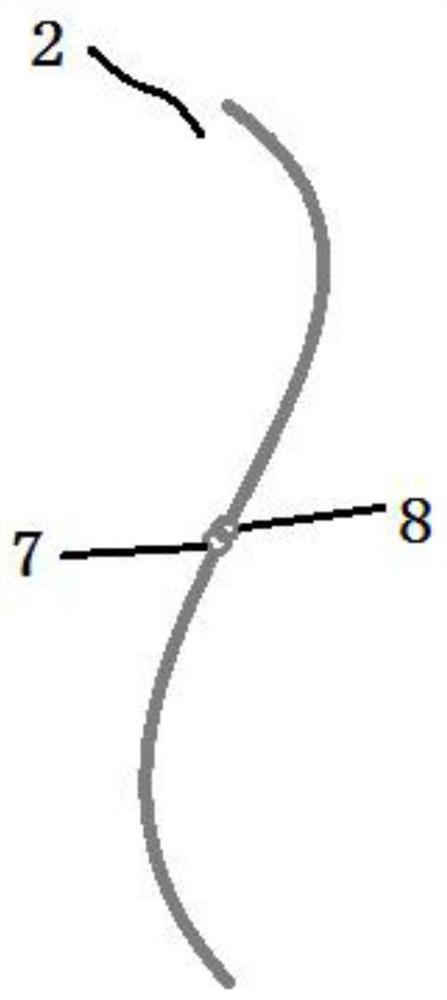

[0035] The end-to-end connection is a buckle connection, wherein one end has a closed buckle structure 7, and the end connected to it has an open buckle structure 8. When connecting, the open buckle structure 8 is inserted into the closed buckle structure 7 along the opening. , and press the opening to become smaller to avoid falling off from the opening. The end-to-end connection can also be welded, glued or socketed.

[0036] The end-to-end connection is the middle part of the elongated S-shaped buffer rib 2, that is, each connected section is a C-shaped structure.

[0037]The combined buffer ribs connected by ring fasteners can meet the sufficient radial support force of the bracket, and can also provide buffer for its expansion and con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap