Water injection type escape system for high-rise building

A high-rise building and escape system technology, applied in the field of water-injection high-rise building escape system, can solve the problems of accidental fire damage, blockage, low efficiency, etc., and achieve the effect of avoiding secondary damage and high escape efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

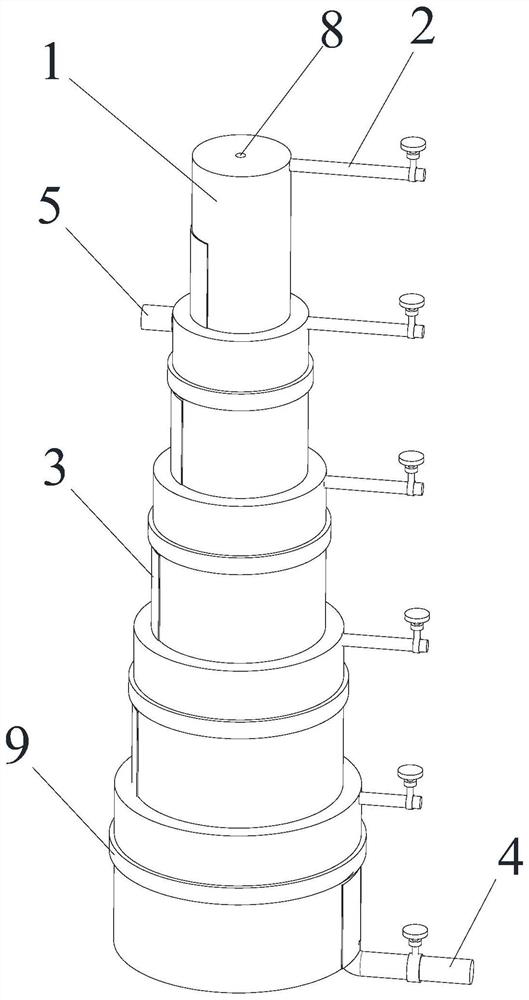

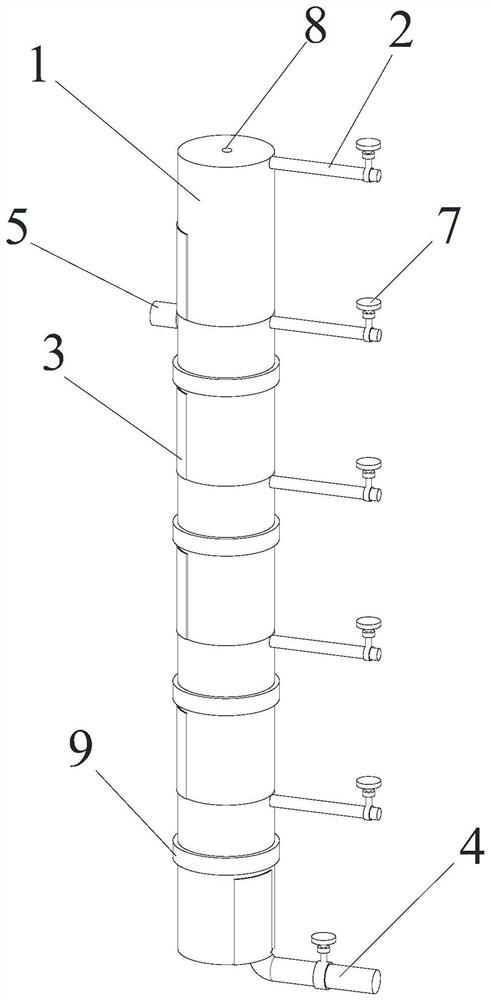

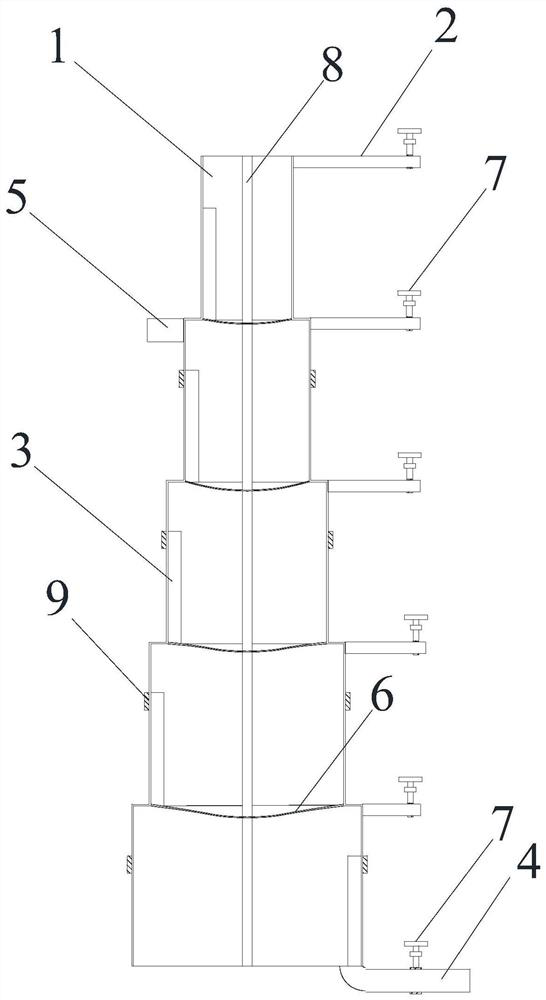

[0036]Every five floors is provided with a main chamber 1, the main chamber 1 is a multi-layer vertical cylinder whose diameter gradually expands, the radius of the main chamber 1 on the top floor is 25 cm, and the radius of the main chamber 1 on the second to fifth floors is 25 cm. Increased by 5cm, there is an anti-falling net 6 between the main chambers 1 on each floor, and a sliding rod 8 is vertically provided inside the main chamber 1. A water outlet pipe 4 is provided at the bottom, and a safety door 3 is provided on each main cavity 1 . The outer walls of the main cavity 1 on the second to fifth floors are provided with reinforcing rings 9 for increasing the bearing capacity of the main cavity 1 . The diameter of the outlet pipe 4 is 10 cm, and the outlet pipe 4 is connected to the communication pipe 5 of the next main chamber 1, and the communication pipe 5 is arranged on the top of the second main chamber 1.

Embodiment 2

[0038] Every five floors is provided with a main cavity body 1, and the main cavity body 1 is the same vertical cylinder of diameter, and the average radius of the main cavity body 1 of each floor is 25cm, and an anti-falling net 6 is arranged between the main cavity body 1 of every floor, The inside of the main chamber 1 is vertically provided with a sliding rod 8 , the water inlet pipes 2 of each floor are connected with the main water pipes of the households on each floor, the bottom of the main chamber 1 is provided with a water outlet pipe 4 , and each floor of the main chamber 1 is provided with a safety door 3 . The outer walls of the main cavity 1 on the second to fifth floors are provided with reinforcing rings 9 for increasing the bearing capacity of the main cavity 1 . The diameter of the outlet pipe 4 is 10 cm, and the outlet pipe 4 is connected to the communication pipe 5 of the next main chamber 1, and the communication pipe 5 is arranged on the top of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com