3D automatic laser cutting device

A laser cutting and automatic technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive, and cannot realize the synchronous cleaning of cutting residues at the same time, and achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

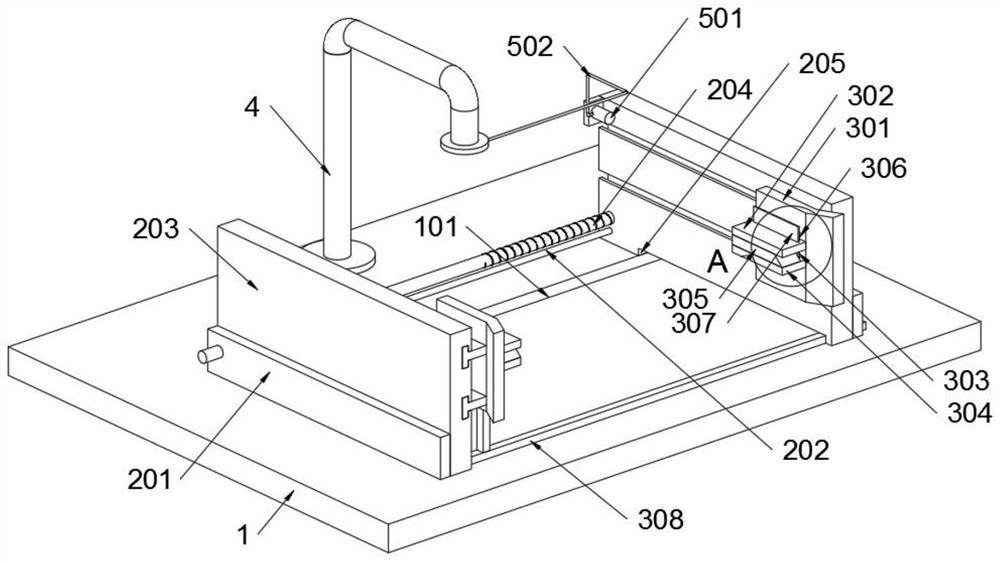

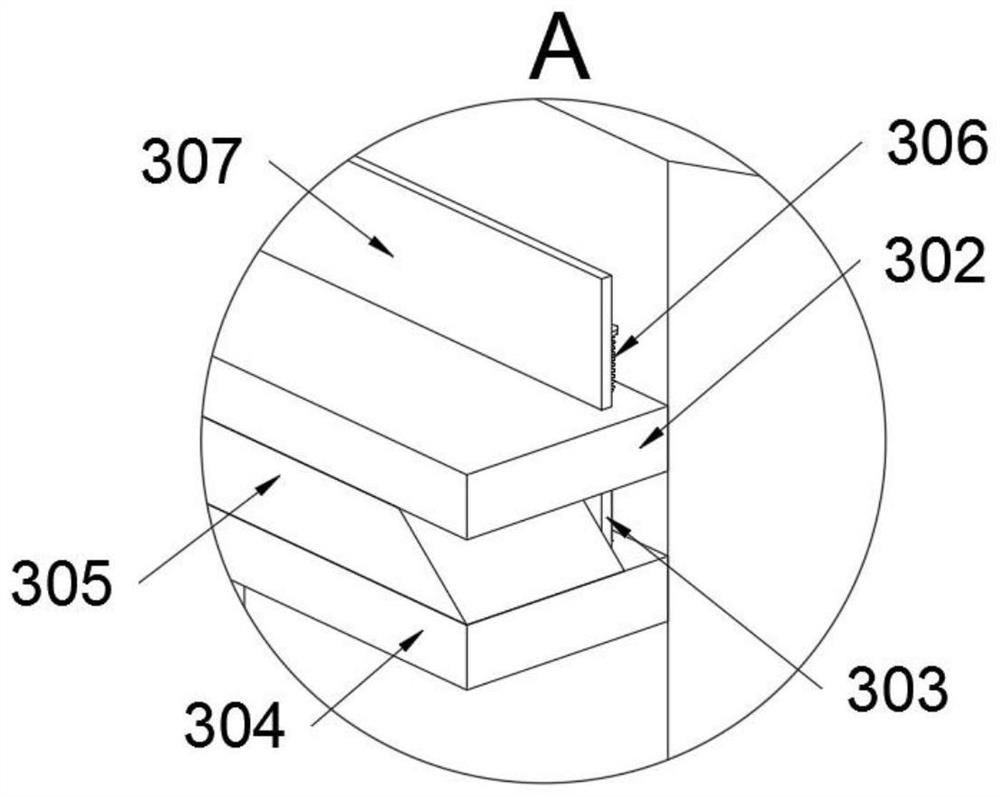

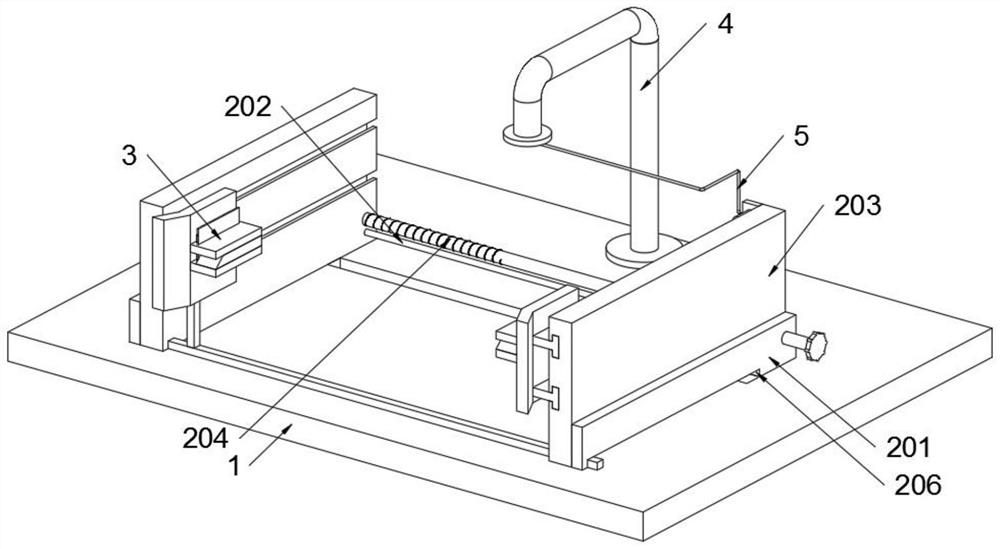

[0061] as attached figure 1 to attach Figure 8 Shown:

[0062] The present invention provides a 3D automatic laser cutting device, comprising a base 1;

[0063] The base 1 is a rectangular block structure;

[0064] Base 1 includes:

[0065] A slag discharge hole 101, the slag discharge hole 101 is opened on the base 1, and the slag discharge hole 101 is a rectangular hole structure;

[0066] An adjustment structure 2, the adjustment structure 2 is installed on the base 1;

[0067] There are two clamping structures 3 in total, and the two clamping structures 3 are installed on the adjusting structure 2 .

[0068] Reference as figure 1 , the regulation structure 2 includes:

[0069] The seat body A201, the seat body A201 is welded on the base 1, and a sliding rod A202 is welded on the seat body A201;

[0070] There are two boards 203, and there are two boards 203, and the two boards 203 are slidably connected to the sliding rod A202;

[0071] Adjusting rod 204, the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com