Undercut removing mechanism of injection mold

An injection mold and upside down technology, applied in the field of tripping mechanism, can solve the problems of low strength, low cost, cumbersome mechanism, etc., and achieve the effects of high product quality, smooth demoulding, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

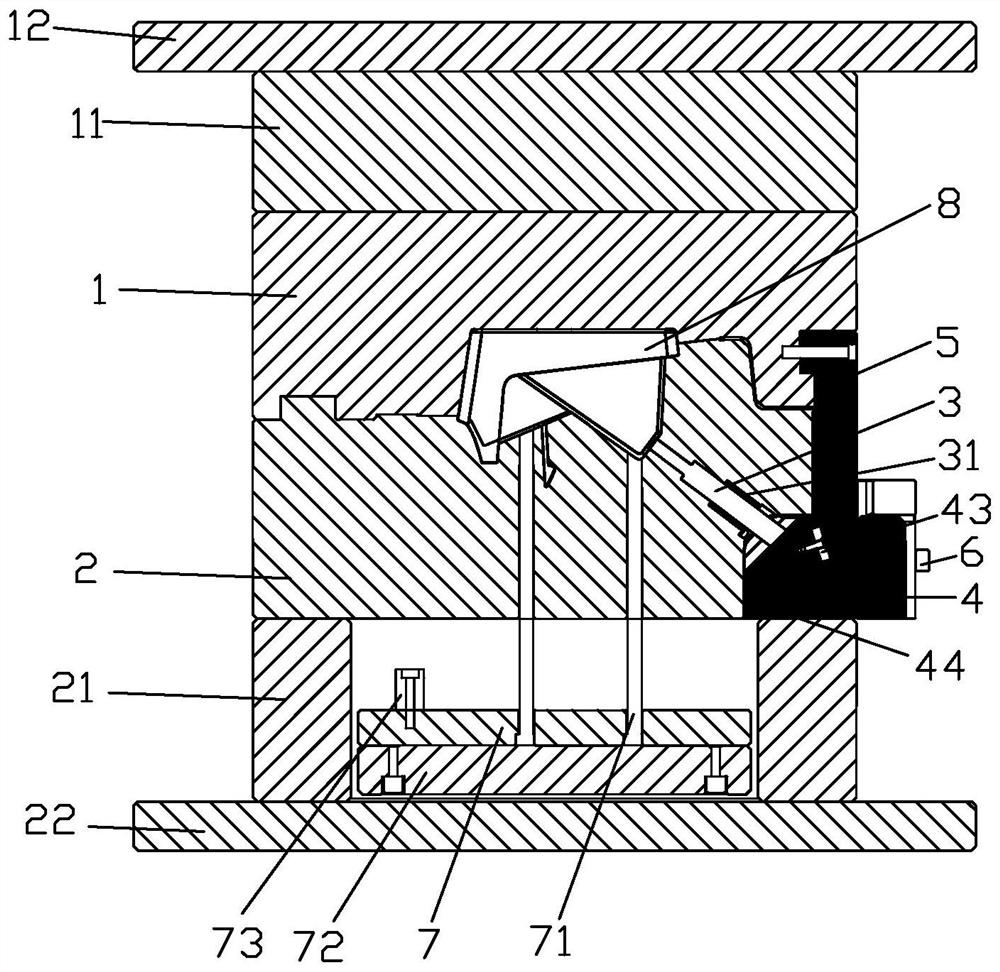

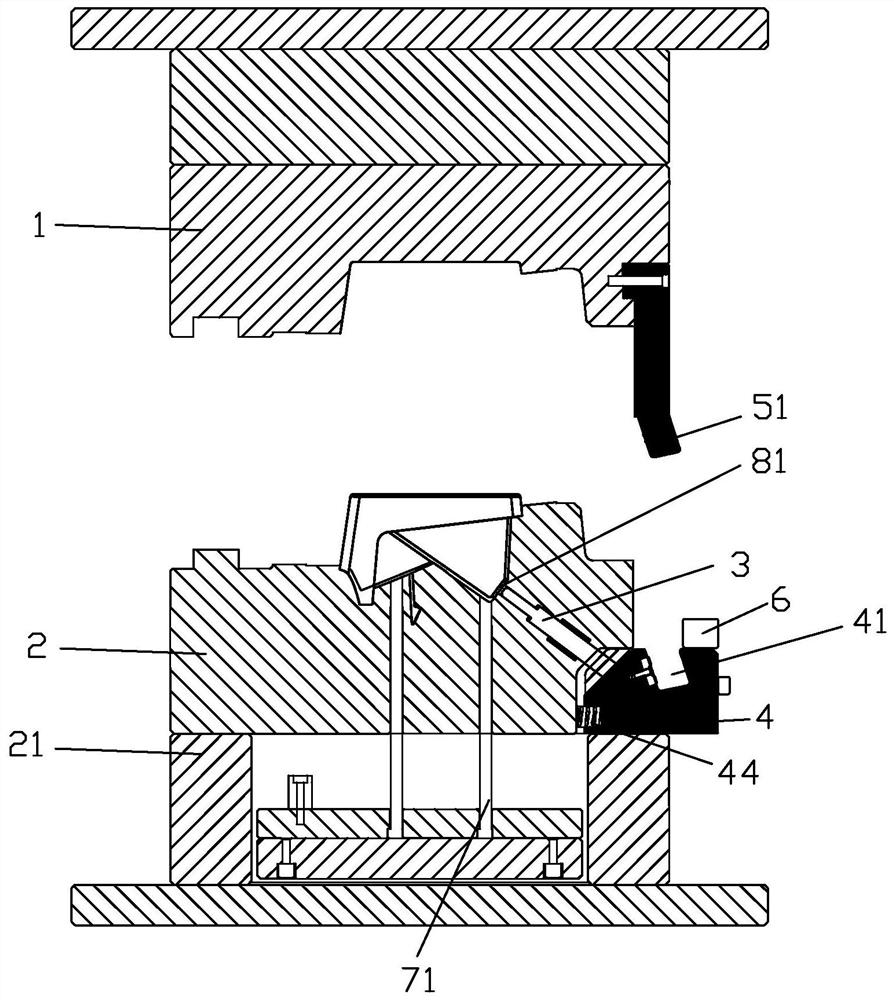

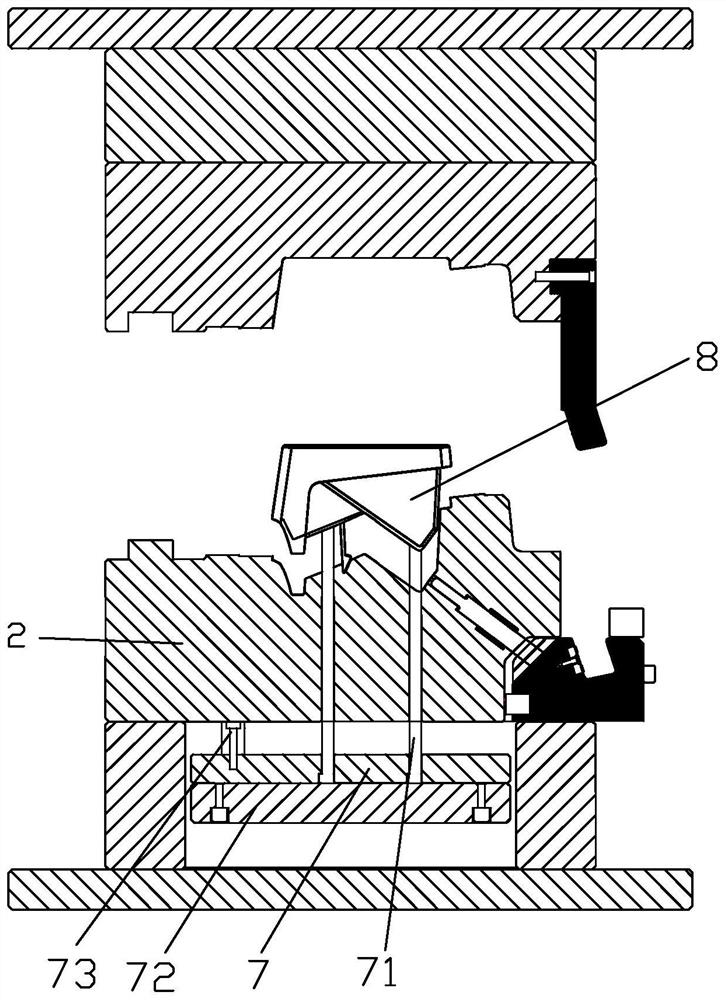

[0041] like figure 1 , figure 2 , image 3 As shown, a detachment mechanism of an injection mold includes:

[0042] The upper web 12 and the lower abdomen 22 are connected below the upper web 12, and the heat flow plate 11 is connected to the heat flow board 11, and the lower abdomen 22 is connected to the lower belt 21, and the surface 21 is connected to the core 2. The core 2 forms a space for injection molding between the core 2 and the cavity 1. The upper pin plate 7 and the lower top needle plate 72 are provided in the space between the core 2 and the lower abdomen 22, and the upper needle plate 7 extends upward, and the top rod 71 extends into the injection space, on the top of the top The protruding limit block 73 is protruding.

[0043]Also included, the chipper 3, the slider 4, the oblique wedge member 5, and the limit piece 6. The oblique wedge 5 integrally a long strip structure having a rectangular cross section, including a clutch wedge 51 at the upper extension 52 and...

Embodiment 2

[0050] like Figure 5 , Image 6 As shown, a detachment mechanism of an injection mold is substantially the same as that of Example 1, and the difference is that the wedge portion 51 includes a plurality of slug 511, and the block 511 is a rectangular structure, including one end block. And several middle plugs. A swallow ridge is provided on one side of the end block, and a dovetail ridge is provided on one side of the middle block, and a dovetail tank is provided on the other side. The socket 511 extends in the direction of the clad wedge portion 51, that is, the lash tank 41 depth direction, adjacent insert 511 is fitted with the slide 41 groove bottom by the tail ridge and the dovetail slot, and the slope 41 groove is provided with the socket 511. Slot 411, slot 411 is a dovetail tank. The diagonal wedge portion 51 length and the depth of the chute 41 are changed by the transfer of the diagonal wedge portion 51 and the chute 41. like Figure 5 As shown, there are two middle slots...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap