Asphalt mixture stirring device capable of automatically feeding fibers

A technology of asphalt mixture and mixing device, which is applied in roads, road repairs, roads, etc., can solve the problems of increasing the variability of fiber asphalt mixture, easy adhesion of fibers to the mixing head, uneven fiber mixing, etc., and achieve improvement performance, ensuring continuity and uniformity, and improving the effect of distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

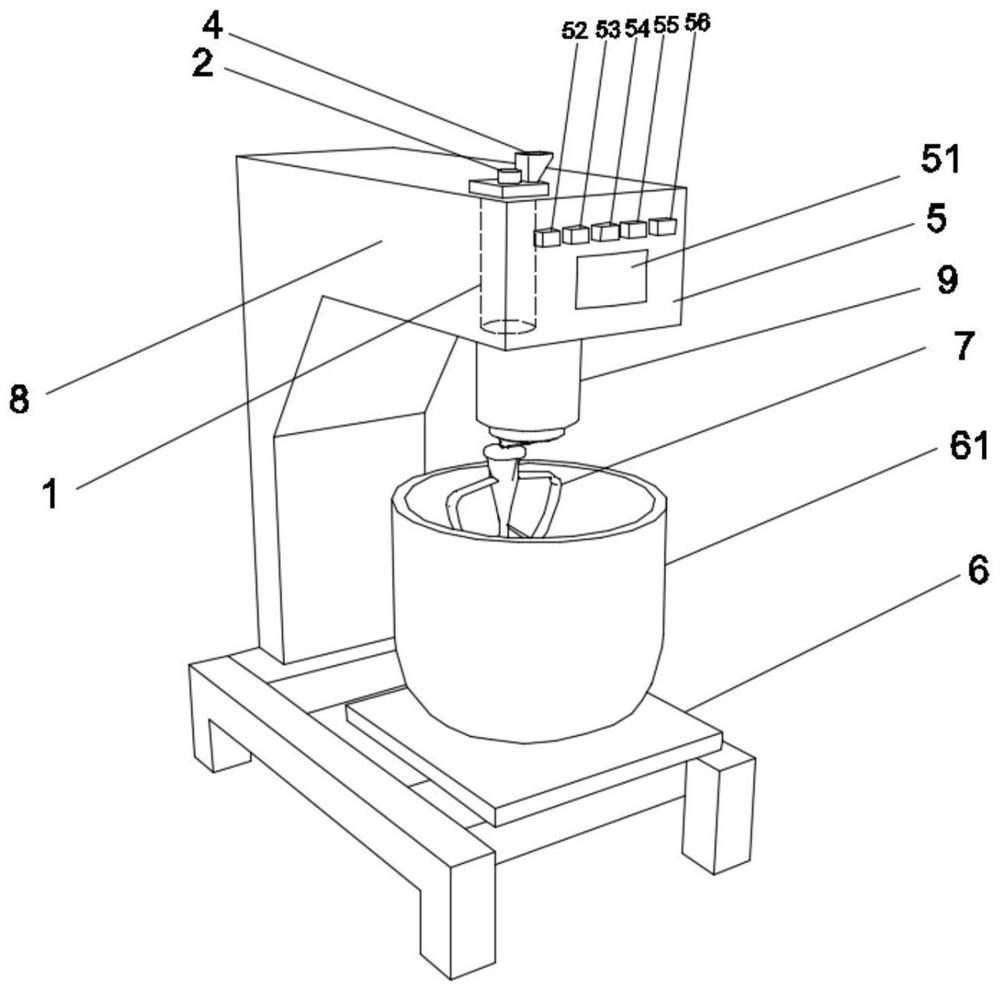

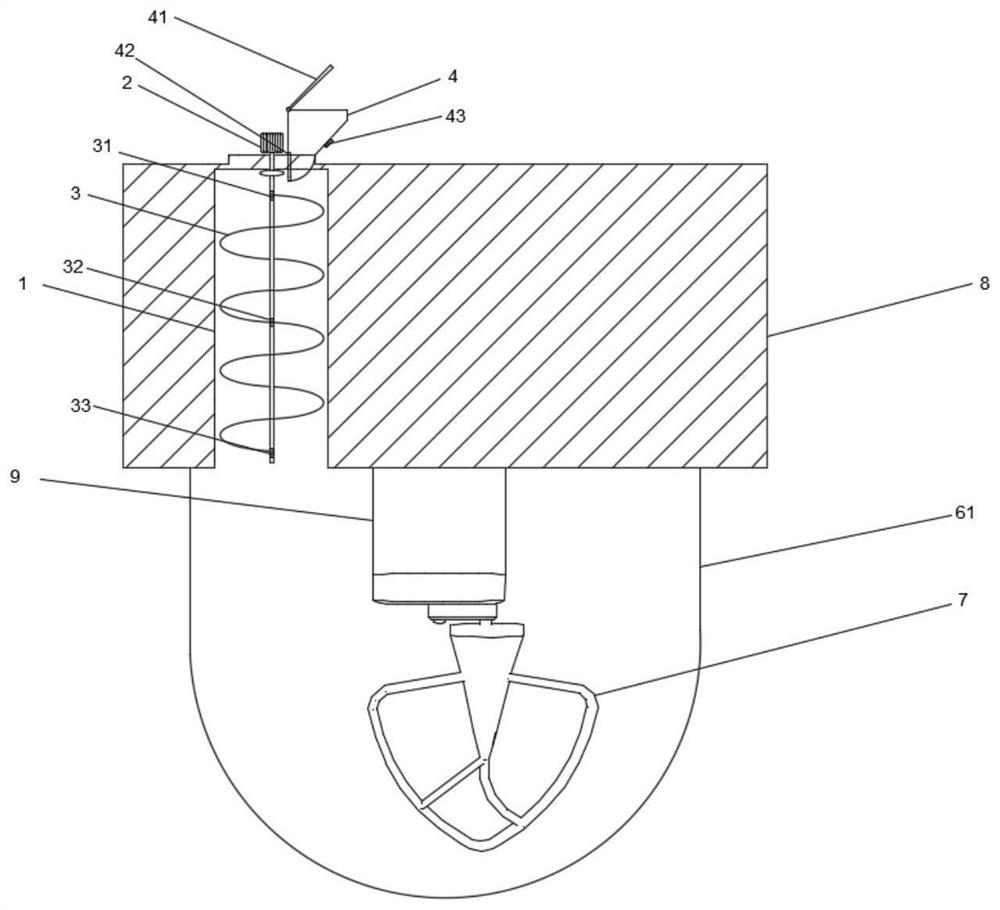

[0021] Such as figure 1 , 2 As shown, the asphalt mixing device for automatic fiber input of the present invention includes a liftable platform 6 with a support arm 8, a heating and mixing pot 61 placed on the liftable platform 6, an upper end and a support arm 8 upper end The mixing blade 7 connected to the gearbox 9; the fiber bin 4 and the fiber mixing chamber 1 are also arranged at the upper end of the support arm;

[0022] The upper opening of the fiber stirring chamber 1 is connected to the lower opening of the fiber silo 4, and the lower opening of the fiber stirring chamber 1 faces the upper opening of the heating and stirring pot 61;

[0023] A fiber stirring blade 3 is arranged in the fiber stirring chamber 1 , and the upper end of the fiber stirring blade 3 is connected with a fiber stirring motor 2 .

[0024] As an improvement, a closable top cover 41 is provided at the upper end of the fiber silo 4 , and a closable bottom cover 42 is provided at the lower end th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com