A kind of non-adhesive bonding composite filter material manufacturing device and using method thereof

A composite filter material and manufacturing device technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., to achieve the effects of tight combination, increased air permeability, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

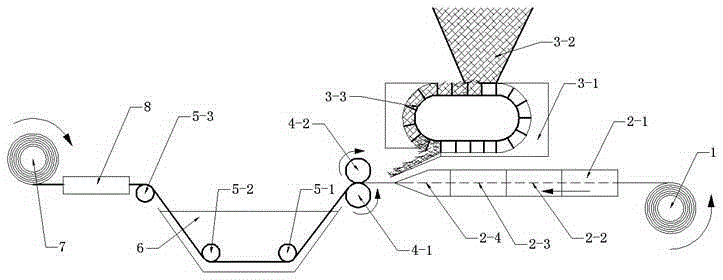

Image

Examples

Embodiment 1

[0022] Example 1: The heat-resistant fiber filter material a uses basalt fiber filter material, the short fiber b is made of polypropylene (PP), and the fiber length is 20mm. There is a temperature gradient in the fourth-level heating components, and the first-level heating components 2-1 will The surface temperature of the filter material a is increased to 50~75°C, the second stage heating part 2-2 raises the surface temperature of the heat-resistant filter material a to 100~125°C, and the third-stage heating part 2-3 heats the surface temperature of the heat-resistant filter material a The temperature is increased to 150-175°C, and the fourth-stage heating assembly 2-4 increases the surface temperature of the heat-resistant filter material a to 175-200°C. The falling speed of short fiber b is 75mg / (m 2 s). The temperature of the cooling water pool is maintained at 50~60°C, and the temperature of the oven is 100°C.

[0023] The heat-resistant fiber filter material a passes ...

Embodiment 2

[0024]Example 2: Take the filter material obtained in Example 1 and the ordinary glued filter material to make a filter of the same specification, and perform an application effect test according to the GB / T6165-2008 national standard. Both filters achieve high filtering effect, and the filtering efficiency is ≥99.9%. However, in the process of continuously holding dust on the filter material, when the resistance of the filter material reaches 2 times of the initial resistance (that is, the test termination condition is reached), the service time of the filter made by using the filter element obtained in Example 1 is increased by 20%.

Embodiment 3

[0025] Example 3: Heat-resistant fiber filter material a is made of basalt fiber filter material, short fiber b is made of polyester fiber (PET), and the fiber length is 20 mm. There is a temperature gradient in the four-level heating part. The first-level heating part 2-1 raises the surface temperature of the heat-resistant filter material a to 80~100 °C, and the second-level heating part 2-2 raises the surface temperature of the heat-resistant filter material a to 160 °C. ~180°C, the third heating element 2-3 raises the surface temperature of the heat-resistant filter material a to 220-200°C, and the fourth heating element 2-4 raises the surface temperature of the heat-resistant filter material a to 260-280°C. The falling speed of short fiber b is 75mg / (m 2 s). The temperature of the cooling pool is maintained at 50~60°C, and the temperature of the oven is 100°C.

[0026] The heat-resistant fiber filter material a passes through the heating unit 2 to heat the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com