Gutter device of prefabricated steel structure roof system

A roofing system and steel structure technology, applied in the direction of roofing, roof covering, building structure, etc., can solve problems such as blockage, affecting rainwater diversion effect, weakening rainwater diversion effect, etc., and achieve the effect of improving the use effect and smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

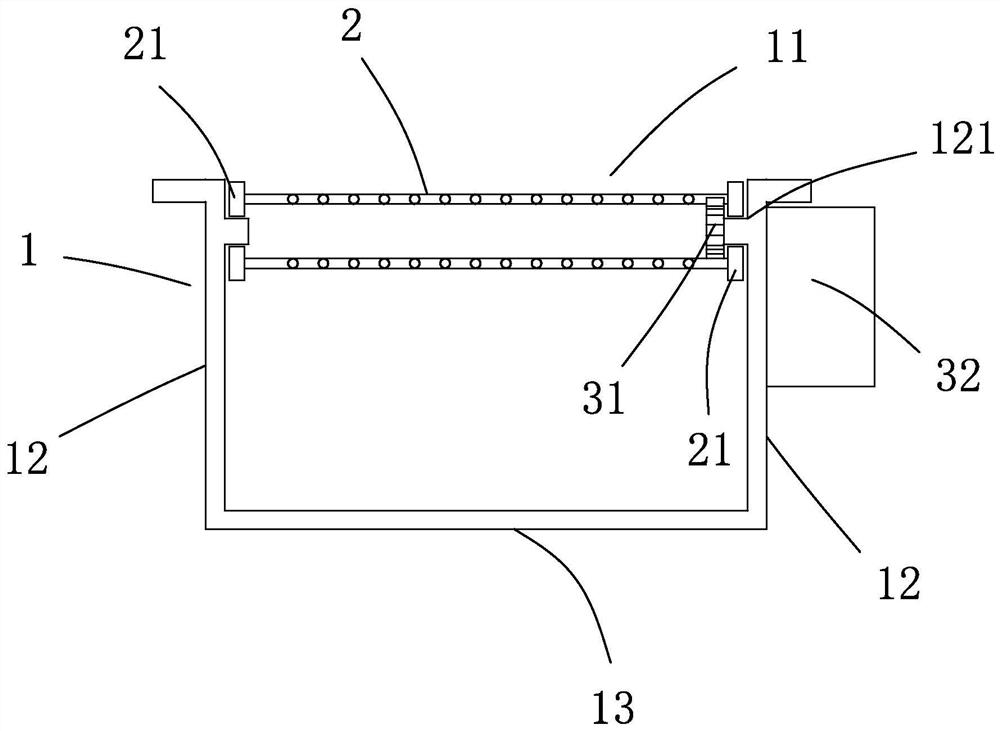

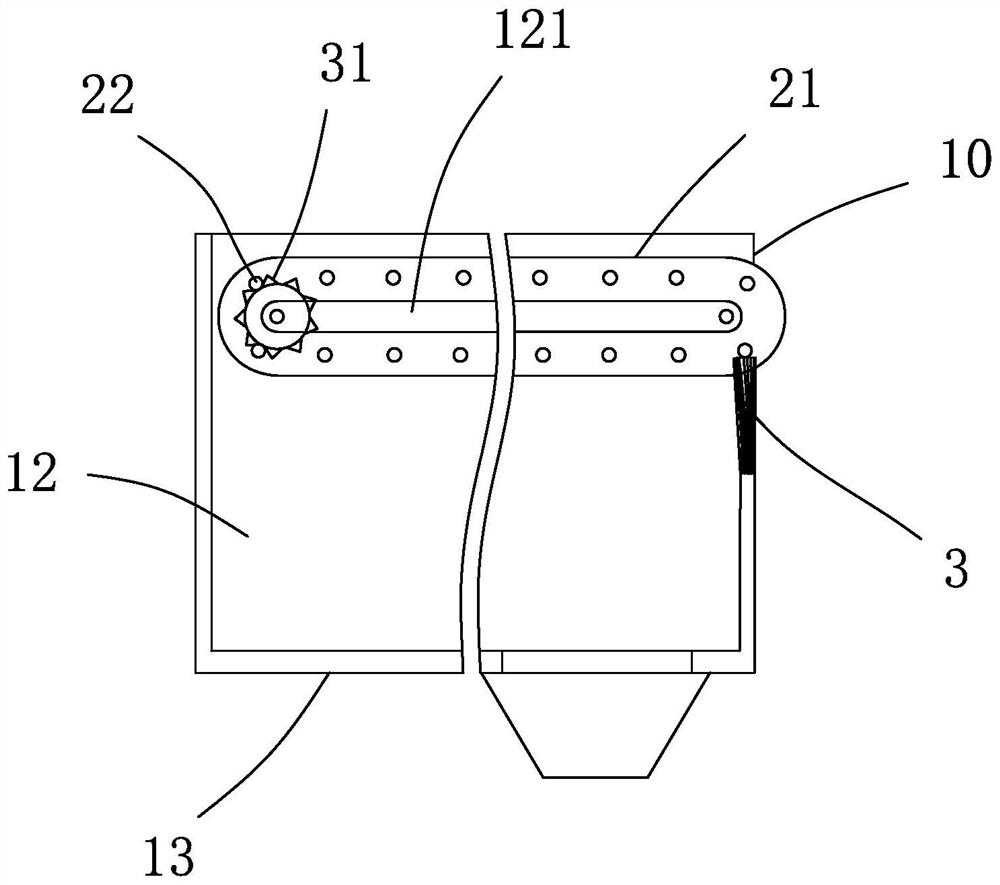

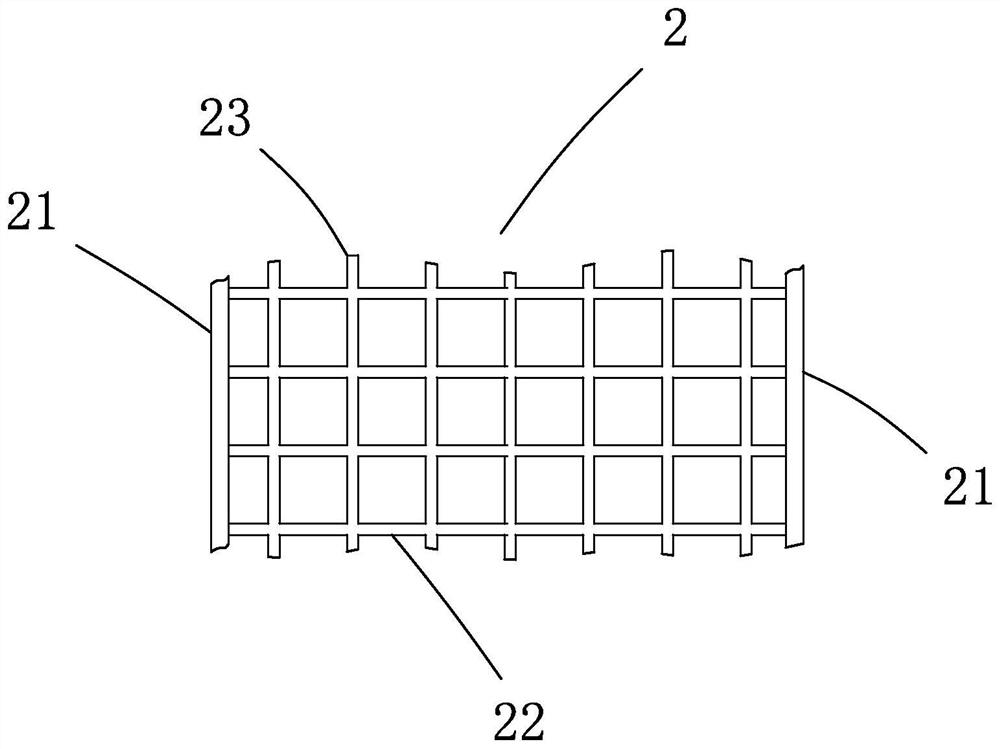

[0015] Embodiments of the gutter device of the fabricated steel structure roof system of the present invention are as follows Figure 1-3 As shown: includes a drainage section 1, the drainage section 1 includes a top opening 11, two side walls 12 and a bottom wall 13, the top opening 11 of the drainage section is covered with a filter belt 2, the filtering The end-to-end connection of the belt 2 is an annular structure, and the two side walls 12 are provided with guide rails 121 for guiding and sliding on both sides of the filter belt 2, and at least one end of the drainage section is provided with a filter belt that cooperates with the filter belt 2 The foreign matter on the 2 is scraped to the scraping mechanism on the outside of the drainage section 1, and the drainage section 1 is provided with a driving mechanism for driving the filter belt 2 to rotate circularly along the guide rail.

[0016] Such as figure 2 As shown, one end of the drainage section 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com