Construction method for integral reinforcing structure of integrated opening-free F-shaped aluminum clamping formwork

A construction method and a technology for strengthening structures, which are applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, building structures, etc., and can solve the problem of inability to apply bay windows of different heights and cumbersome reinforcement and installation operations , high reinforcement cost and other issues, to achieve the effect of convenient reinforcement installation, convenient reinforcement construction, and low replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

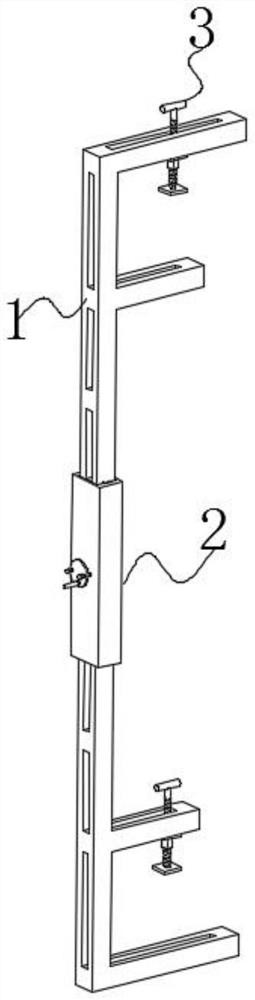

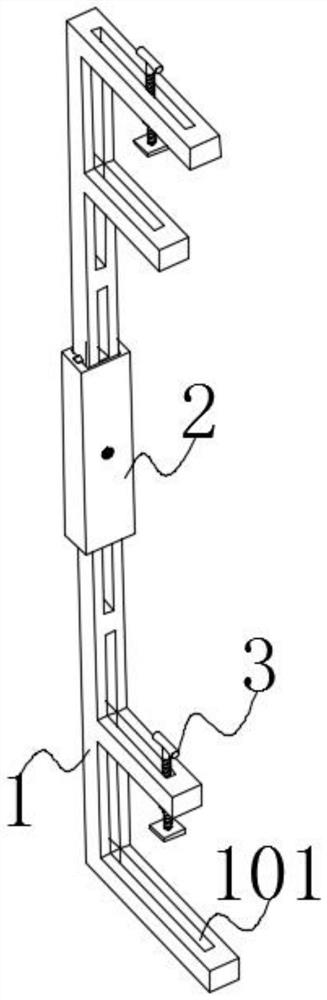

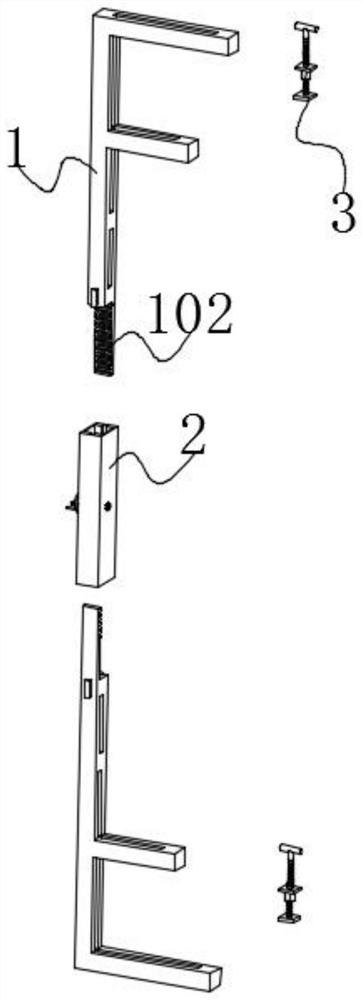

[0056] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0057] The present invention is an integrated opening-free F-type card aluminum formwork overall reinforcement structure construction method, including the reinforcement construction and the installation of the upper bay window aluminum formwork body 5 and the lower bay window aluminum formwork body 6 before the reinforcement construction.

[0058] see Figure 7-9 As shown, the installation method of the upper bay window aluminum formwork body 5 and the lower bay window aluminum formwork body 6 before reinforcement construction specifically includes the following steps:

[0059] S1: Check the model and quantity of parts corresponding to the position of the installation window against the list of disassembled components

[0060] S2: first carry out the installation of the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com