Undercarriage strength test vertical load loading device

A loading device and strength test technology, which is applied in the direction of measuring devices, aircraft component testing, mechanical component testing, etc., can solve the problems of limited vertical space and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the drawings in the embodiments of the present invention.

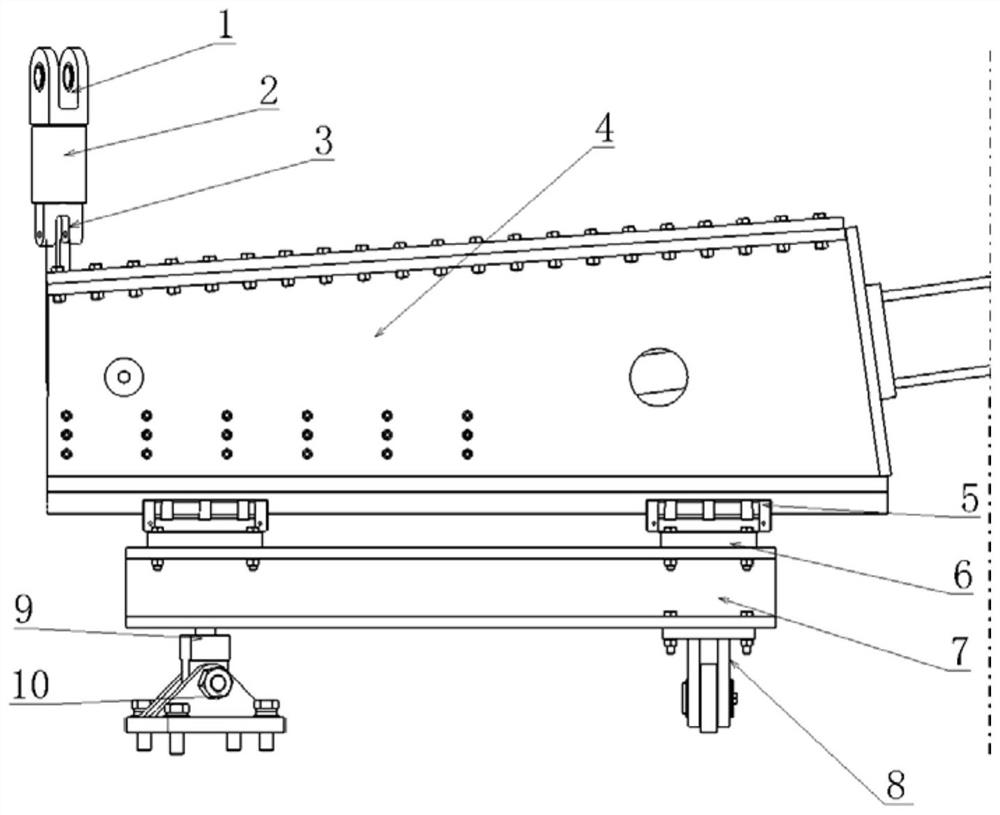

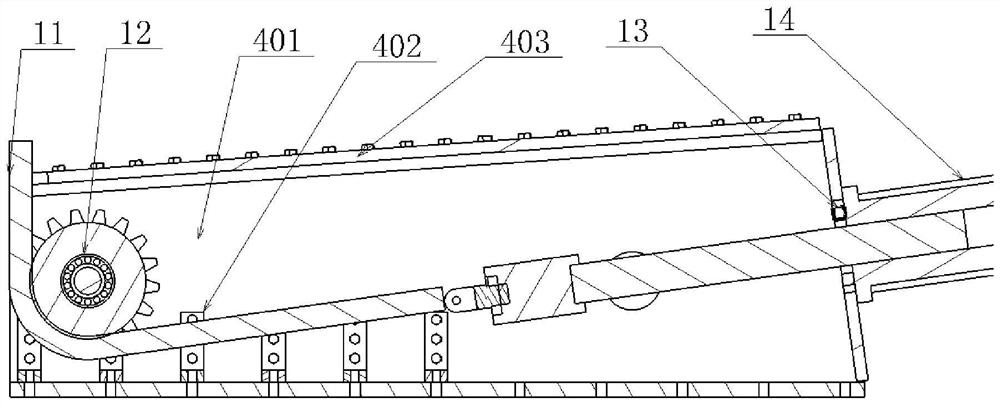

[0046] The front view of the embodiment of the present invention is as follows figure 1 As shown, the main part is the vertical loading beam 4 and the bottom beam 7, figure 2 It is a sectional view of the vertical loading beam 4.

[0047] The vertical loading beam 4 is a box-shaped cross-section, and there is enough space between the two webs and the upper and lower flanges. It is mainly composed of a loading beam main body 401, a beam reinforcing rib 402, and a beam cover plate 403 connected by bolts.

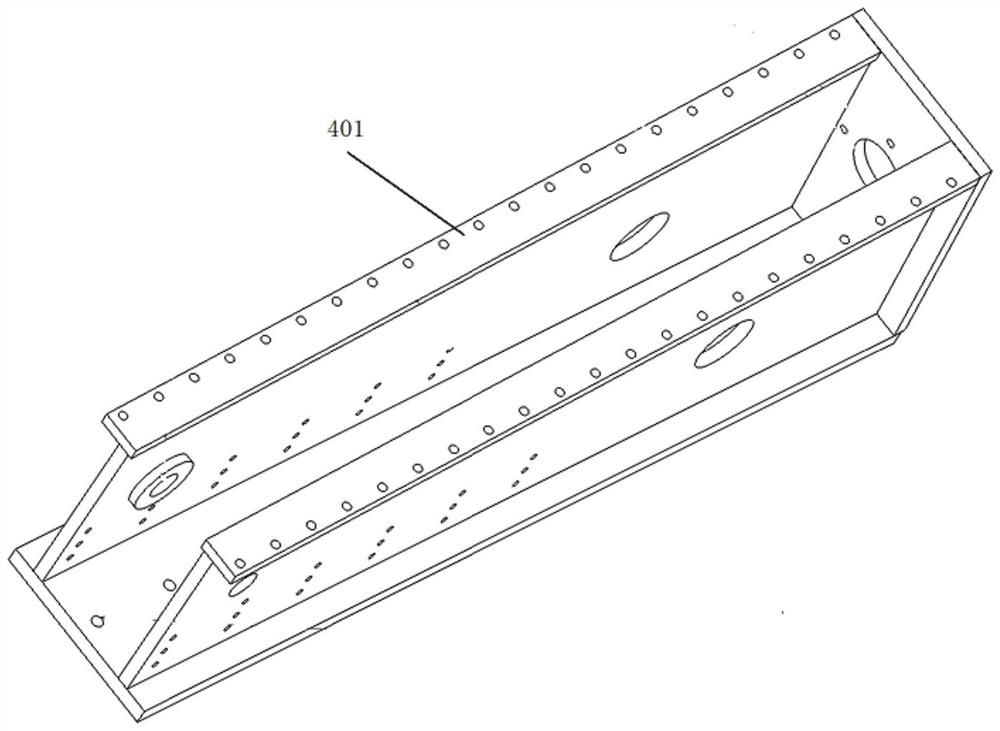

[0048] Loading beam body 401 as image 3 As shown, the large opening beam with U-shaped cross-section is welded by steel plates, and the lower flange and web of the beam are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com