An intelligent switch processing equipment

A technology of intelligent switch and processing equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

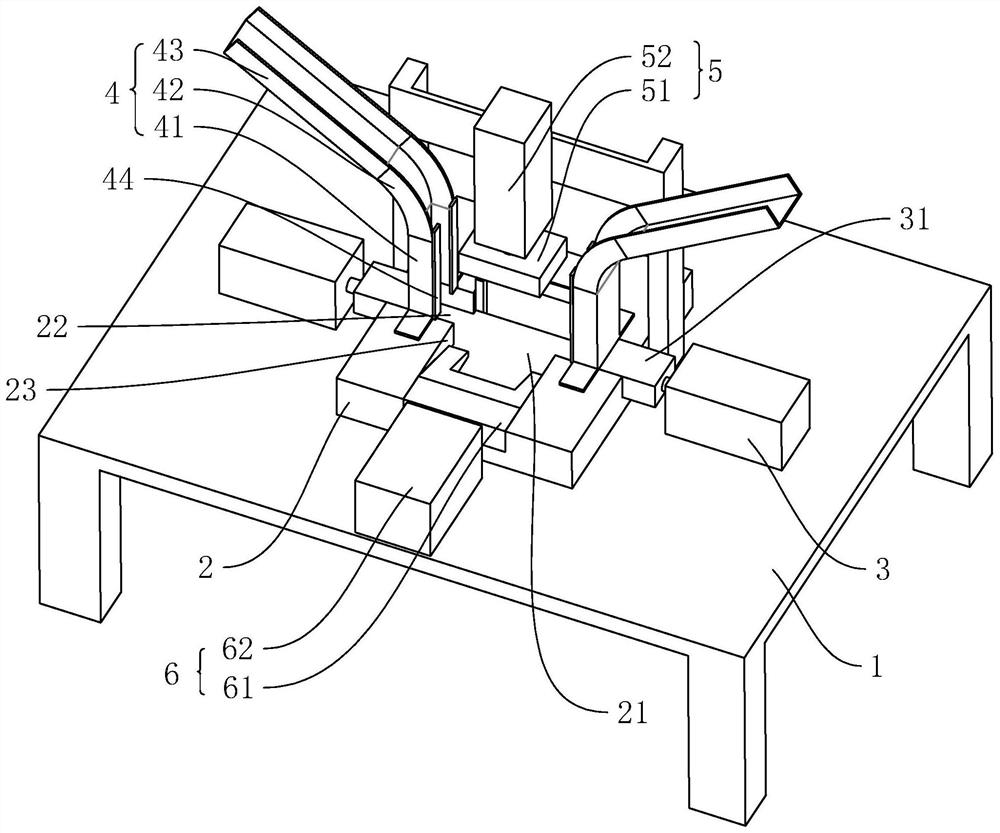

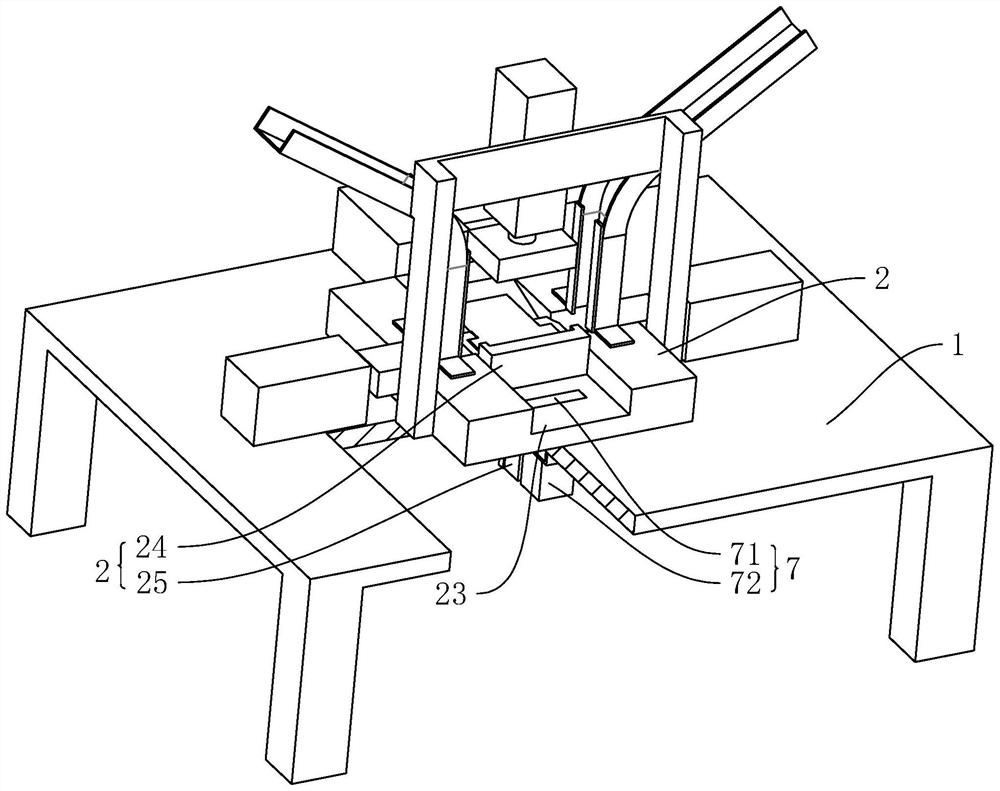

[0029] The application will be described in further detail below in conjunction with the accompanying drawings.

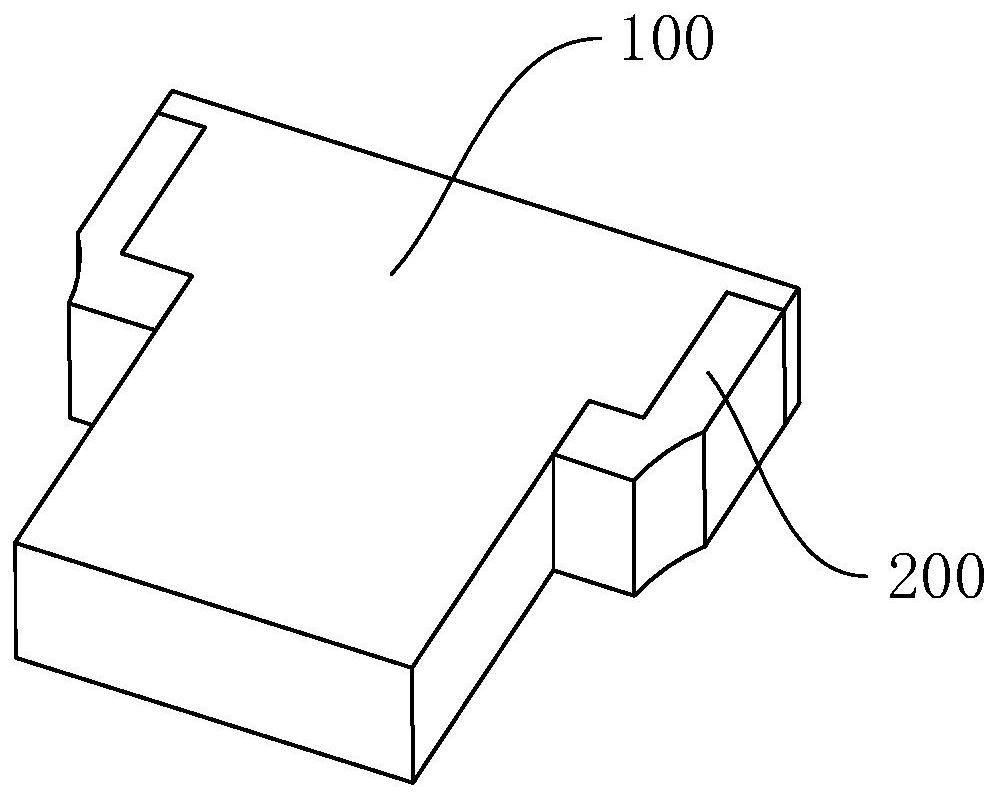

[0030] A kind of intelligent switch processing equipment disclosed in this application, such as figure 2 shown and matched with the control figure 1 , including a base 1 , a mounting seat 2 disposed on the base 1 , and two sets of mounting drivers 3 for pushing the mounting ears 200 to move toward the body 100 . The mounting seat 2 is fixed on the base 1 with bolts, and the upper end of the mounting seat 2 is provided with a receiving groove 21 for accommodating the body 100 , and the body 100 is placed in the receiving groove 21 so as to limit the position of the body 100 . The side walls of the receiving groove 21 near the installation part of the body 100 provided inside are provided with positioning grooves 22, the positioning grooves 22 penetrate the upper end surface of the mounting base 2 and the two side walls away from each other, and the mounting ears 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com