Elevator suspended ceiling and elevator car roof

An elevator and ceiling technology, applied in the field of elevator cars, can solve the problems of high pressure on passengers, difficult cleaning and operation, and achieve the effect of low-cost replacement, improving overall comfort, and meeting space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

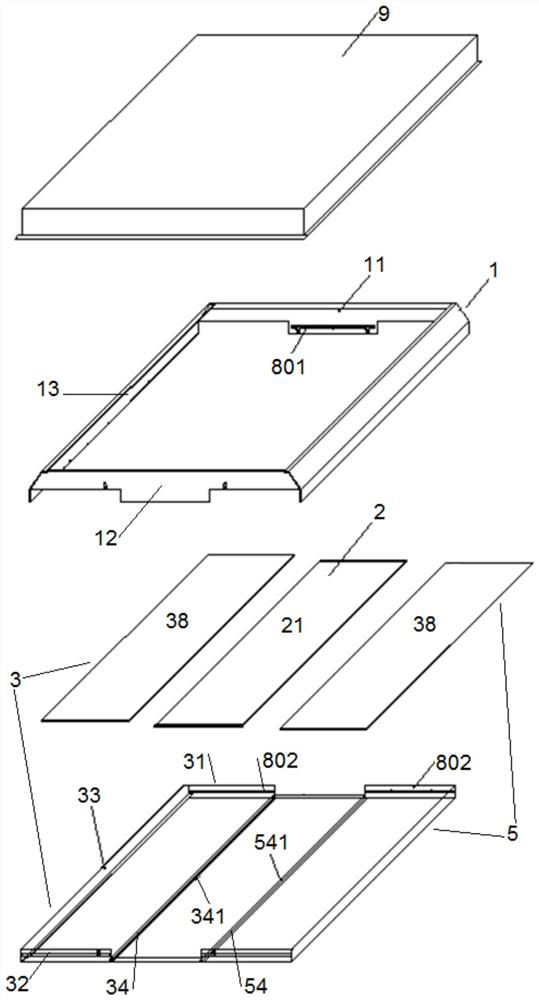

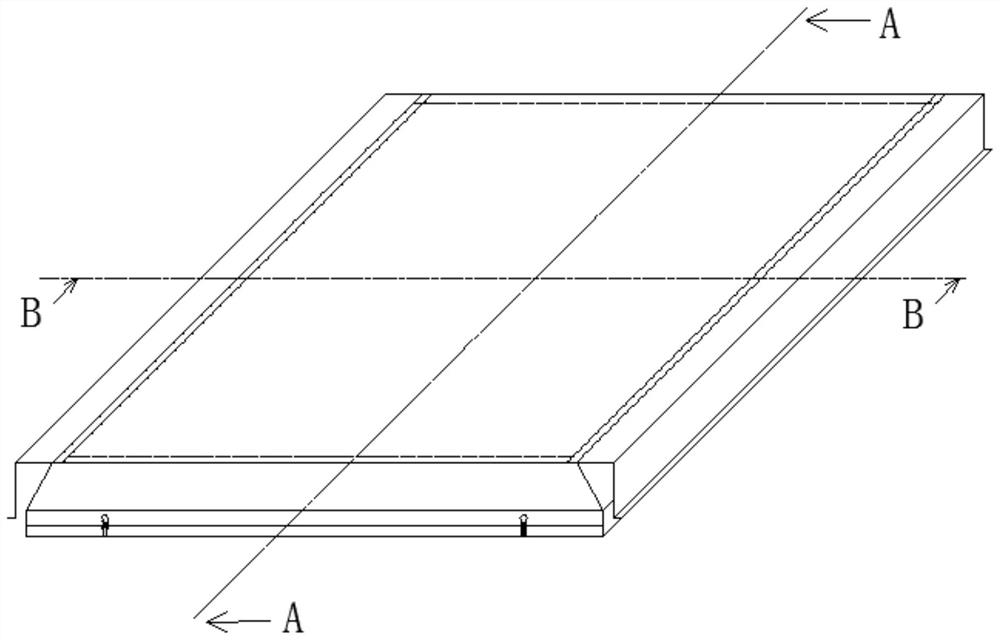

[0059] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the elevator ceiling includes a shade frame 1, a central lighting panel assembly 2, and a first side lighting panel assembly 3;

[0060] The shading plate frame 1 is rectangular;

[0061] The first side lighting panel assembly 3 includes a first side support frame;

[0062] A side lighting board 38 is installed and fixed in the first side support frame;

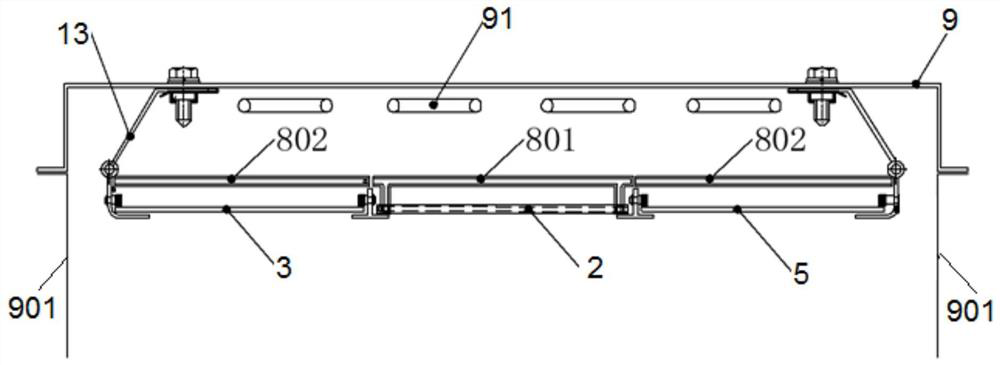

[0063] The upper sides of the front support plate 31 and the rear support plate 32 of the first side support frame are respectively fixed with left and right guide grooves 802;

[0064] The first side support frame is fixedly installed on the right side of the left visor 13 of the visor frame 1, the left part of the front visor 11 and the left part of the rear visor 12;

[0065] A central left support surface 341 bent to the right is formed at the lower end of the right support plate 34 of the first side support frame;

[0066] Such as Figure 5 , ...

Embodiment 2

[0078] Based on the elevator ceiling of Embodiment 1, the front shading plate 11 and / or the rear shading plate 12 of the shading plate frame 1 is provided with a vertical spring limit rod 701 corresponding to the lower part of the vertical groove of the "π"-shaped guide groove 801;

[0079] When the vertical spring limit lever 701 is pressed down, the guide wheel 22 of the central lighting panel assembly 2 is restricted from moving upward along the vertical groove of the "π"-shaped guide groove 801;

[0080] When the vertical spring limiting rod 701 bounces up, the guide wheel 22 of the central lighting panel assembly 2 is allowed to move along the vertical groove of the “π”-shaped guide groove 801 .

[0081] In the elevator ceiling of Embodiment 2, when the central lighting panel assembly 2 needs to be moved up, the vertical spring limit rod 701 pops up, and the central lighting panel assembly 2 is pushed upward to make it follow the vertical direction of the "π"-shaped guide ...

Embodiment 3

[0083] Based on the elevator ceiling of Embodiment 1, such as Figure 12 As shown, the upper sides of the front support plate 31 and the rear support plate 32 of the first side support frame respectively correspond to the right parts of the left and right guide grooves 802, and a transverse spring limit rod 702 is provided;

[0084] When the transverse spring limit lever 702 is pressed down, the guide wheels 22 of the central lighting panel assembly 2 are restricted from moving along the left and right guide grooves 802;

[0085] When the transverse spring limiting rod 702 bounces up, the guide wheel 22 of the central lighting panel assembly 2 is allowed to move along the left and right guide grooves 802 .

[0086] In the elevator ceiling of Embodiment 3, the upper sides of the front support plate 31 and the rear support plate 32 of the first side support frame respectively correspond to the right parts of the left and right guide grooves 802, and a transverse spring limit rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com