Methylene blue sensitizer and its application in photo-Fenton-induced raft reaction

A technology of methylene blue and polymerization reaction, applied in the field of polymer materials, can solve difficult problems such as high efficiency and safety, and achieve the effects of easy acquisition, good time control, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

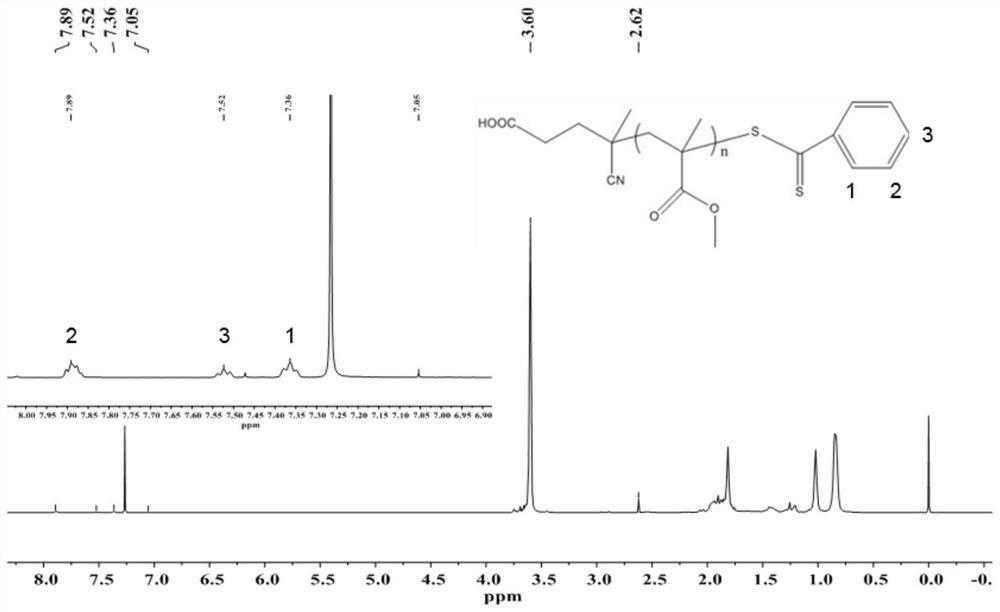

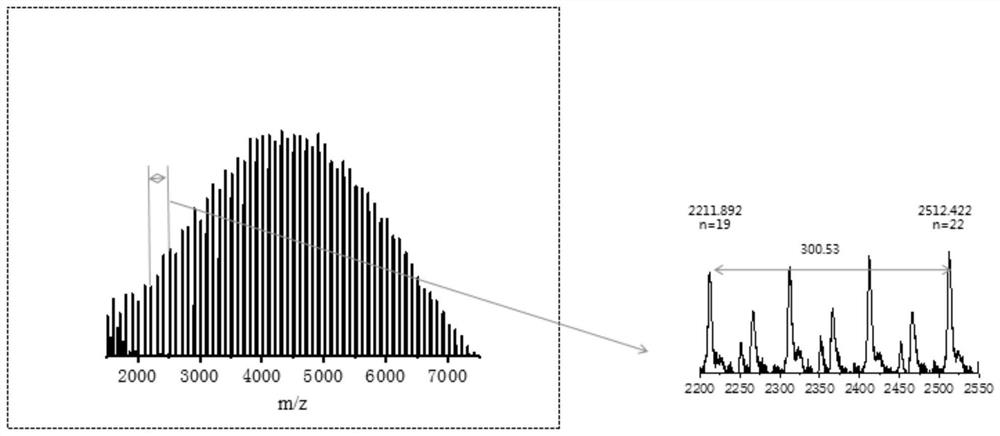

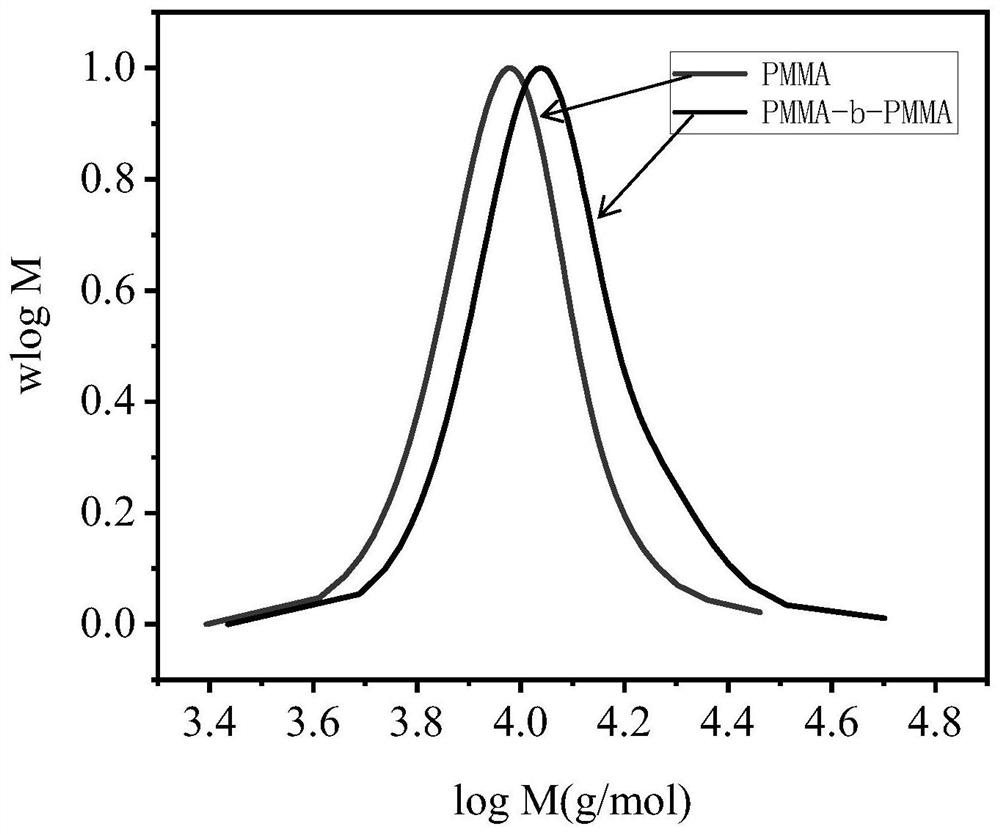

[0044] A kind of polymer 1, its preparation comprises the steps: take 1.6mg methylene blue, 13.1mg CPADB, 17uL H 2 O 2 , 1 mL of methyl methacrylate and 1 mL of DMSO were added to a test tube with a capacity of 5 mL (no need to seal), after which the test tube was placed in a photoreactor, and the reaction was carried out under the irradiation of red light for 0.5 h in frozen methanol. Purification 3 times gave polymer 1.

[0045] The conversion rate was 14% (the percentage of monomers converted to the starting monomers), the molecular weight of the polymer measured by gel permeation chromatography (GPC) was 5290, and the polymer dispersibility index (PDI) was 1.23.

Embodiment 2

[0047] A kind of polymer 2, its preparation comprises the steps: take 1.6mg methylene blue, 13.1mg CPADB, 17uL H 2 O 2 , 1mL methyl methacrylate and 1mL DMSO were added to a test tube with a capacity of 5mL (no need to seal), then the test tube was placed in a photoreactor, irradiated with red light for 1 hour, and purified 3 times in frozen methanol to obtain a polymerization thing 2.

[0048] The conversion rate was 35%, the molecular weight of the polymer measured by GPC was 8933, and the molecular weight distribution PDI was 1.24.

Embodiment 3

[0050] A kind of polymer 3, its preparation comprises the steps: take 1.6mg methylene blue, 13.1mg CPADB, 17uL H 2 O 2 , 1 mL of methyl methacrylate and 1 mL of DMSO were added to a test tube with a capacity of 5 mL (no need to seal), then the test tube was placed in a photoreactor, irradiated with red light for 2 hours, and purified 3 times in frozen methanol to obtain polymerization. item 3.

[0051] The conversion rate was 95%, the molecular weight of the polymer measured by GPC was 11511, and the molecular weight distribution PDI was 1.82.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com