Stretcher type steel spring floating slab track structure

A floating plate and steel spring technology, applied in the directions of track, track laying, track maintenance, etc., can solve the problems of troublesome maintenance, poor practicability, unfavorable damping type vibration isolator maintenance and disassembly and recovery, etc., and is conducive to disassembly, repair and maintenance , Conducive to recycling, and the effect of stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

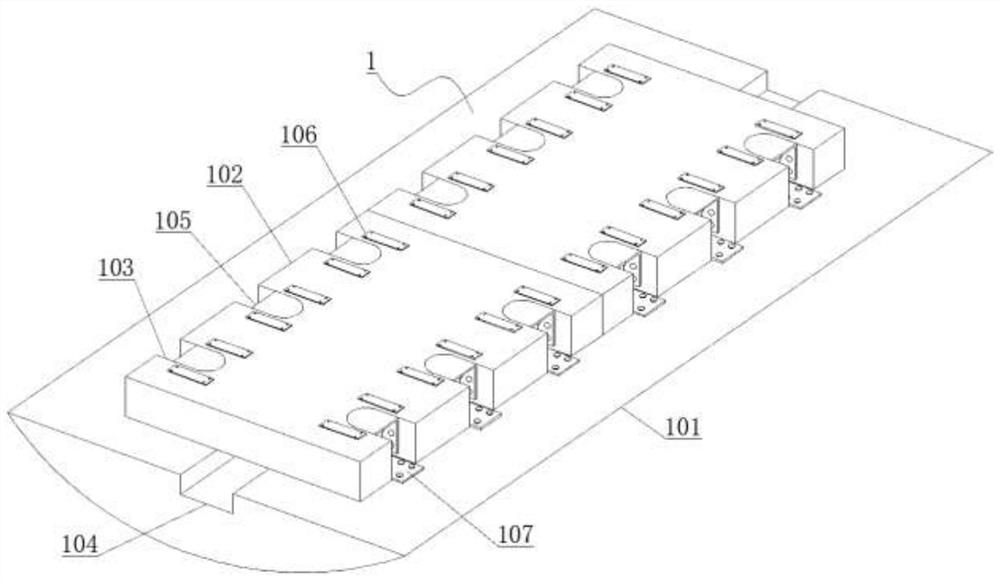

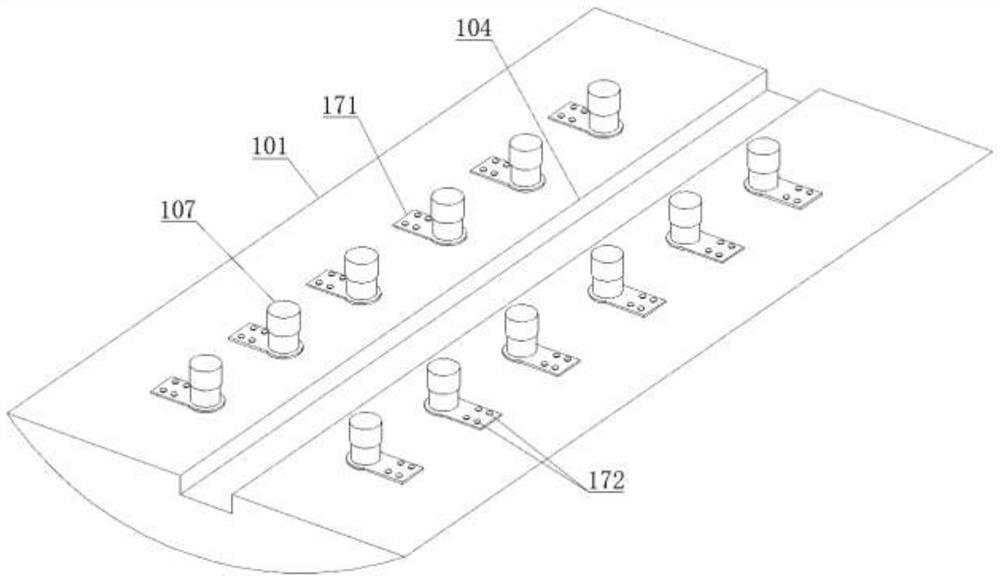

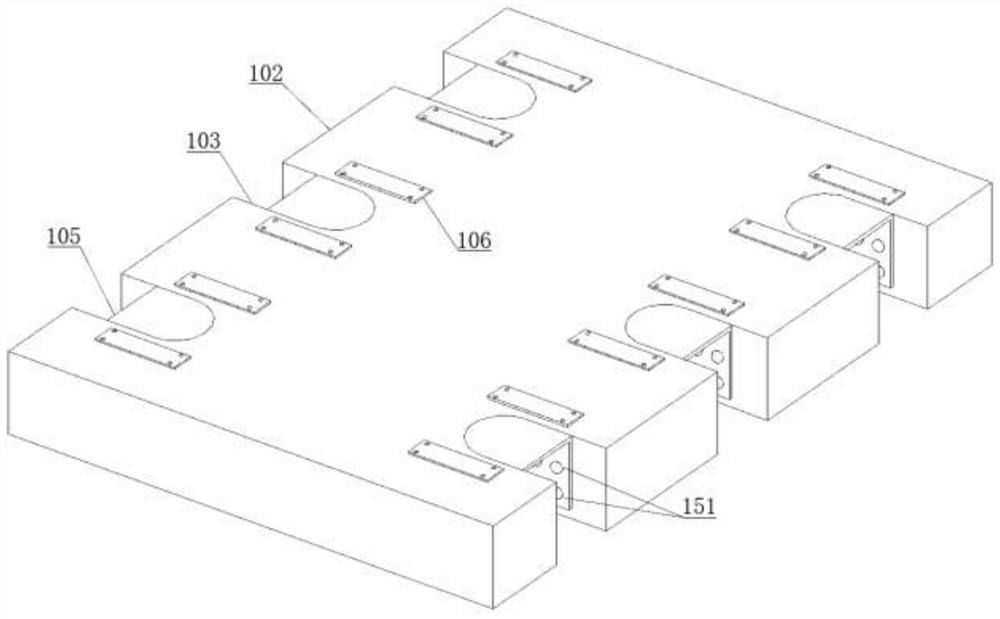

[0020] see Figure 1-Figure 5 , the present invention provides the following technical solutions: a stretcher-type steel spring floating slab track structure, including a track overall structure 1, the track overall structure 1 includes a track support base 101, and the center of the upper surface of the track support base 101 is provided with a base drainage groove 104, and the upper surface of the rail support base 101 is laid with a floating plate 102, and both sides of the floating plate 102 are evenly opened with side-opening installation grooves 103, and the floating plate 102 corresponds to the side-opening installation groove 103 A vibration isolator stretcher 105 is provided at the position, and a floating plate vibration isolator 107 is fixed at the position correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com