Ultra-thick structural steel having excellent brittle crack initiation resistance, and manufacturing method therefor

A kind of steel and brittle cracking technology, applied in the field of ultra-thick structural steel and its manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] Hereinafter, the present disclosure will be described in more detail through examples. It should be noted, however, that the following examples are for illustrative purposes only and are not intended to limit the scope of the present disclosure. The scope of the present disclosure can be determined by the matters described in the claims and matters that can be reasonably inferred therefrom.

Embodiment approach

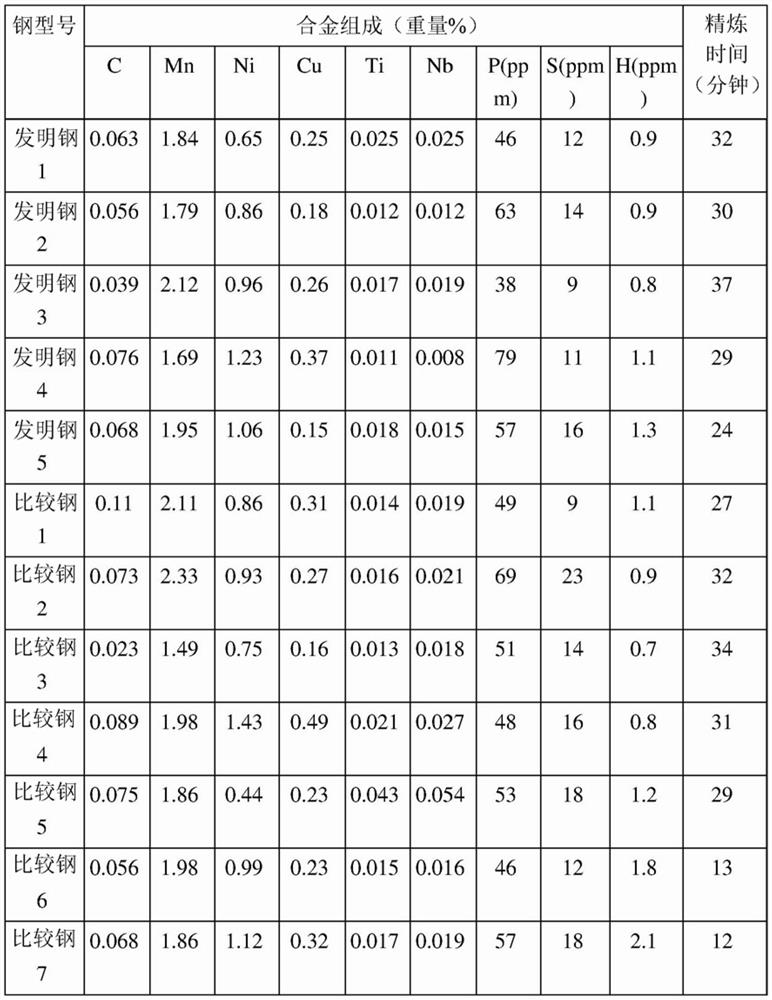

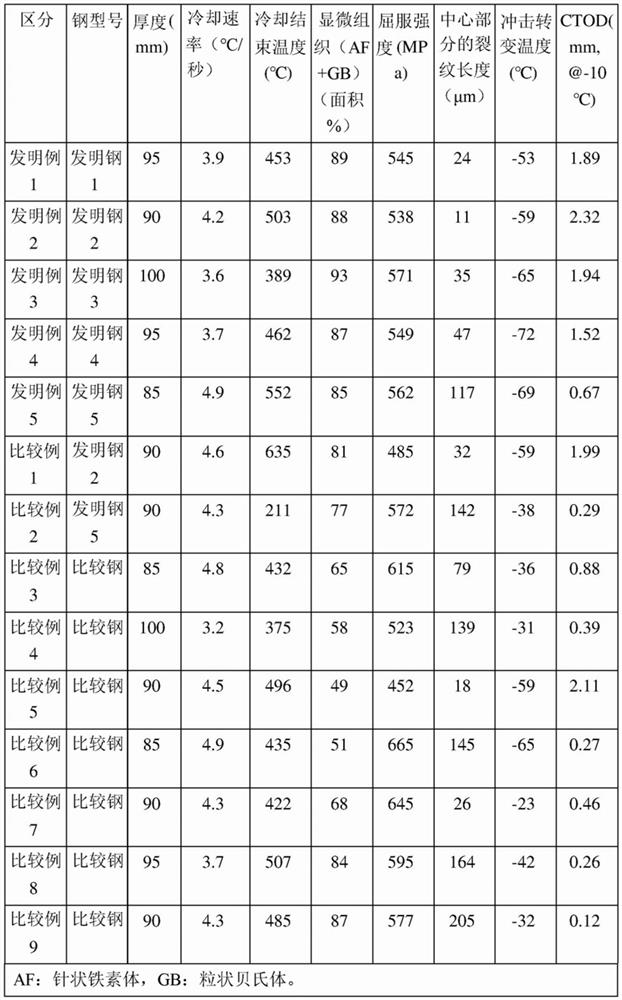

[0052] The molten steel was refined for the RH refining time of Table 1 to prepare molten steel having the alloy composition of Table 1 . The prepared molten steel was continuously cast to produce a billet having a thickness of 400 mm. The billet was reheated to a temperature of 1080°C, and then rough-rolled at a temperature of 1030°C to prepare a bar having a thickness of 200 mm. The cumulative reduction applied during rough rolling was 50%. After the rough rolling, the bars were finish-rolled in a temperature range of 700°C to 850°C to obtain hot-rolled steel products having thicknesses in Table 2, and then cooled under the conditions listed in Table 2.

[0053] The microstructure, yield strength, and impact transition temperature of the center portion of the steel material manufactured in the above manner were measured, and the measurement results are listed in Table 2. In addition, the total thickness CTOD test was performed on the steel at -10°C, and the test results ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com