Primary treatment and recovery device for kitchen metal tool

A preliminary treatment and recovery device technology, applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc., can solve environmental problems such as pollution, waste of cardboard, etc., to solve potential safety hazards, protect the surrounding environment, and solve The effect of splash wounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

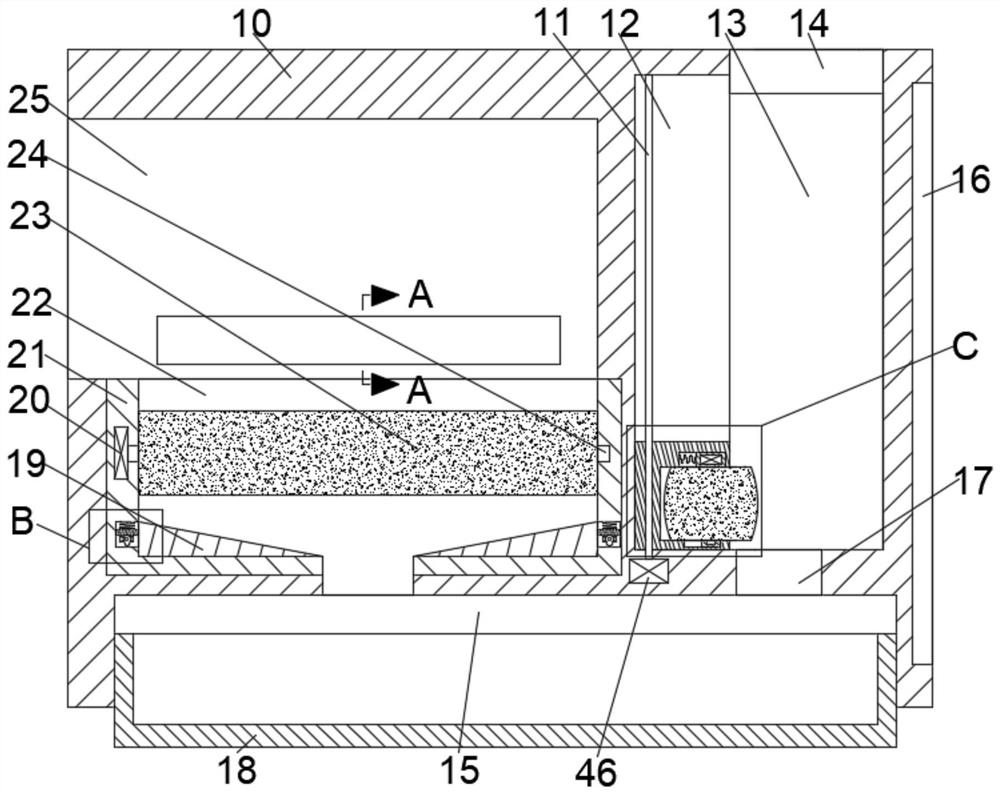

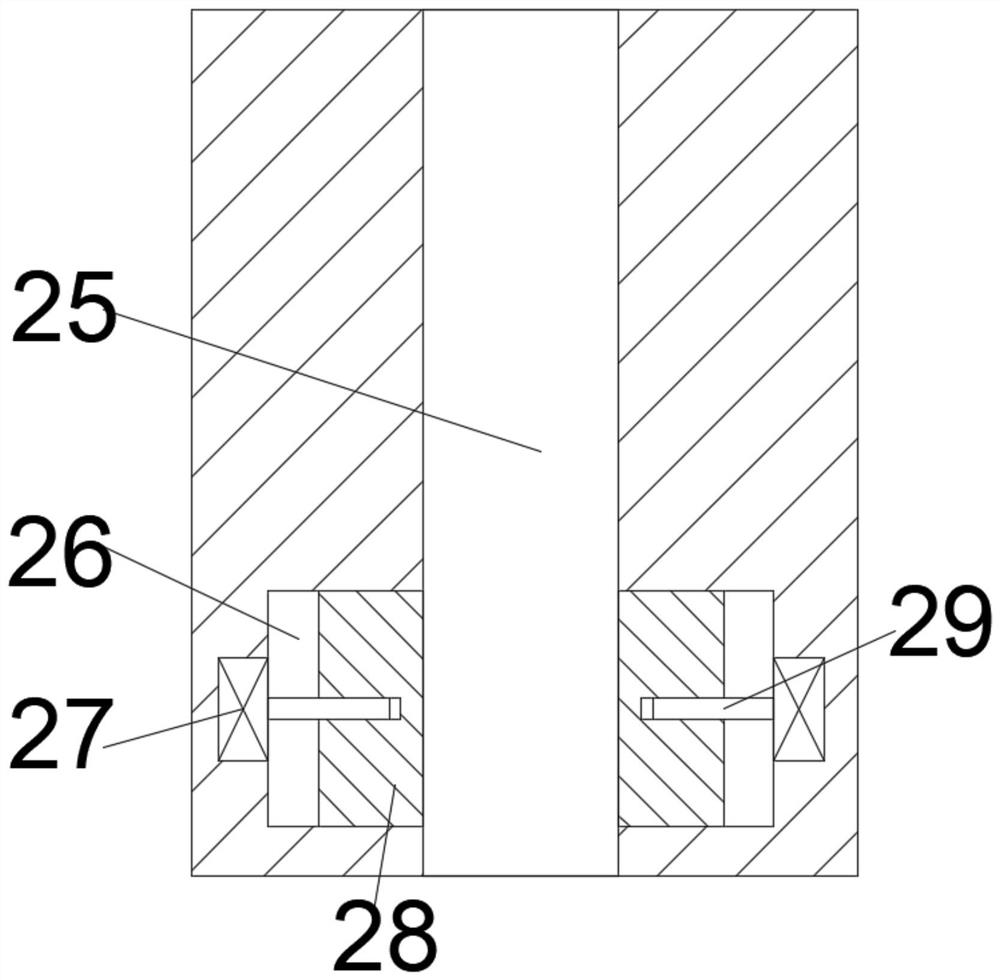

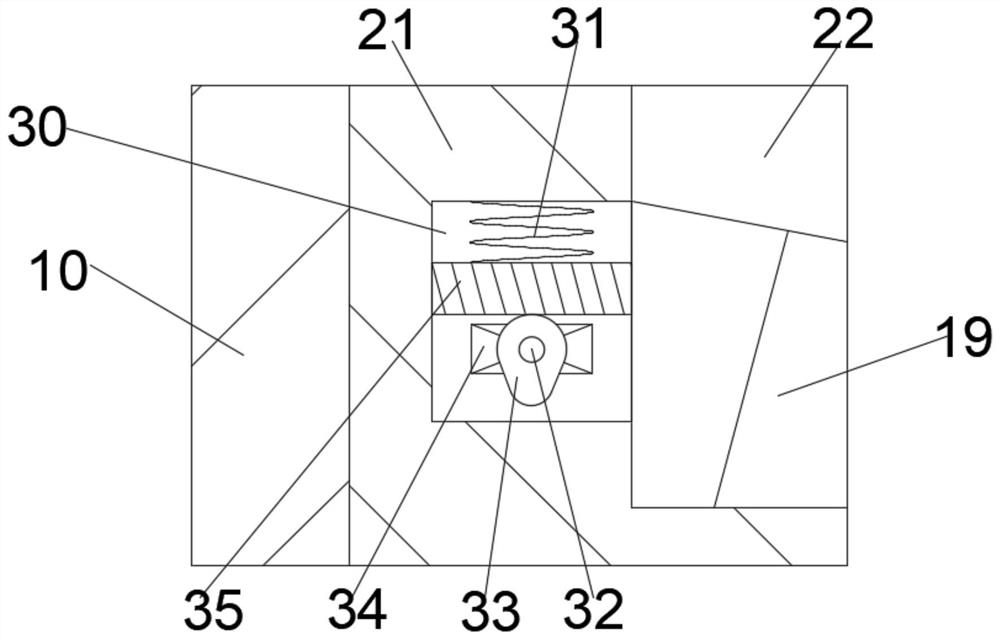

[0023] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0024] In the present invention, unless otherwise stated, the use of orientation words such as "upper, lower" generally refers to the orientation in the assembled and used state. "Inside and outside" means inside and outside relative to the contours of each component itself.

[0025] It should be noted that the terms "first", "second" and the like in the description and claims of the present invention and the above drawings are used to distinguish similar objects, and are not necessarily used to describe a specific sequence or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances for the embodiments of the invention described herein. Furthermore, the terms "compri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap