Supply chain logistics cargo slideway equipment

A supply chain and slideway technology, applied in slideways, transportation and packaging, etc., can solve problems such as uncontrolled sliding speed, easily damaged items, inconvenient use, etc., to improve safety and reliability, increase friction, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

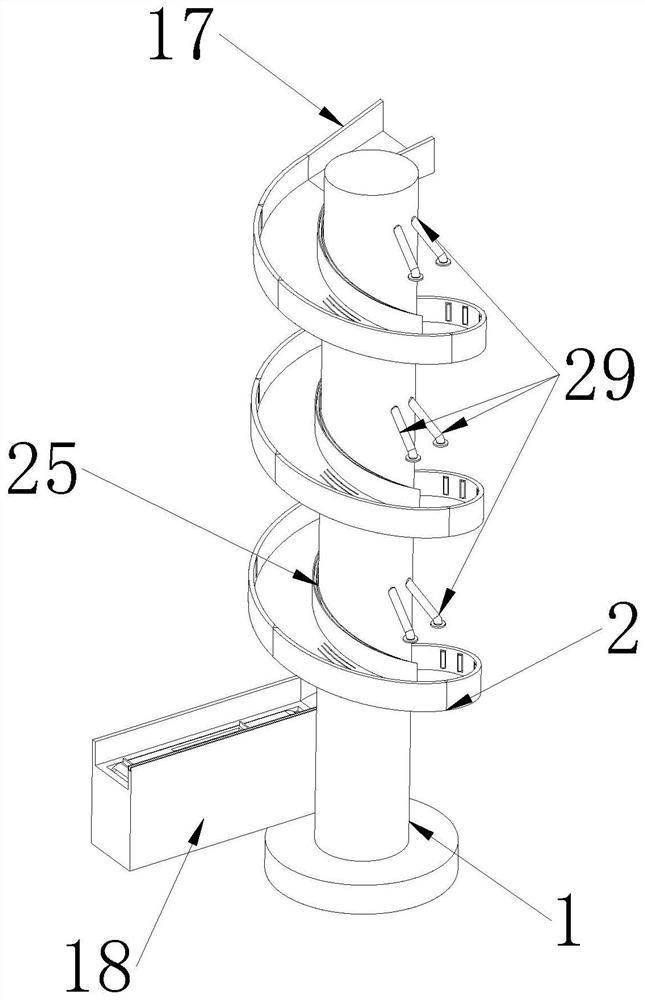

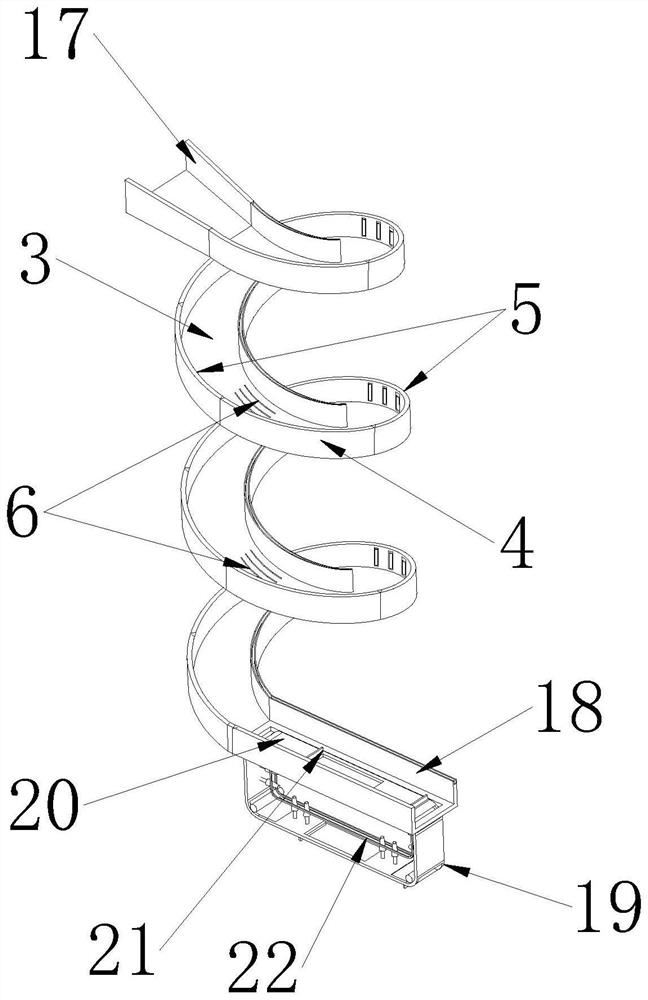

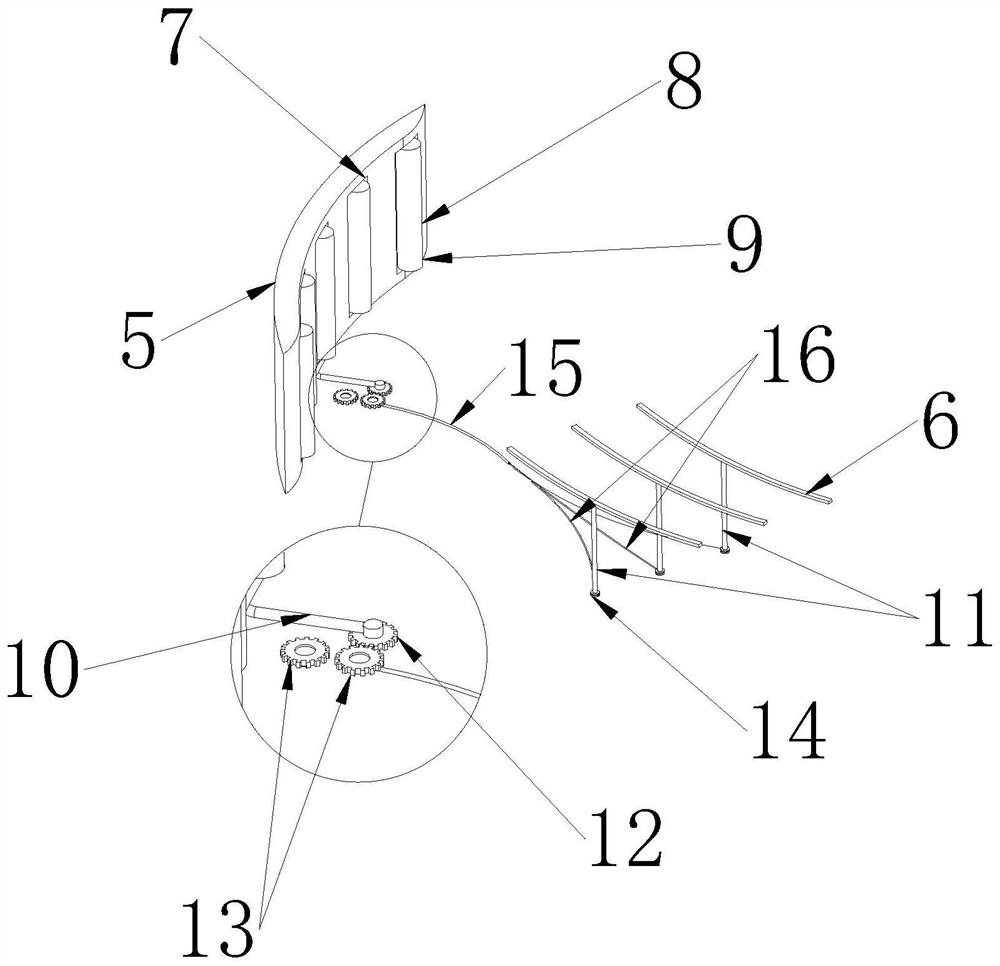

[0028] Example: such as Figure 1-2 As shown, a supply chain logistics cargo slideway equipment includes a central column 1 and a spiral slideway 2 installed outside the central column 1 and arranged along the axial direction of the central column 1. The central column 1 is used to fix and support the spiral The slideway 2, the spiral slideway 2 includes a multi-knotted slideway, and each section of the slideway includes a direction-changing slideway 3 for guiding objects to change the sliding direction, and a direction-changing slideway connecting two adjacent joints. The inclined slideway 4 of 3, the direction-changing slideway 3 is equipped with an elastic buffer plate 5 on the side away from the central column 1, and the side of the elastic buffer plate 5 is movably connected with the side wall of the direction-changing slideway 3 to accept the collision force generated by the object, and Under the action of the collision force, it changes direction and produces displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com