Combined bobbin seat track and production method thereof

A combination and track technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of difficult maintenance and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

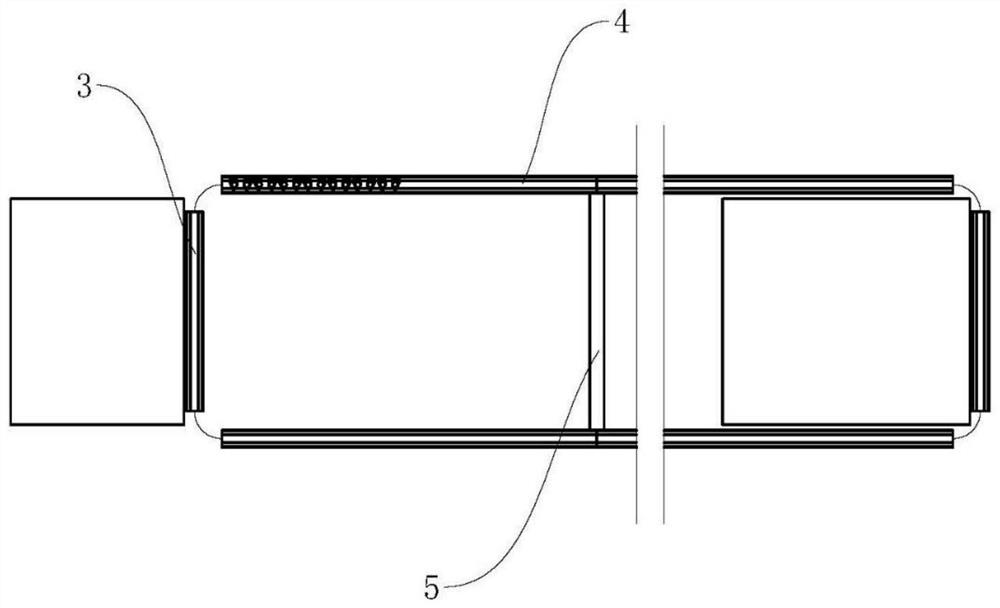

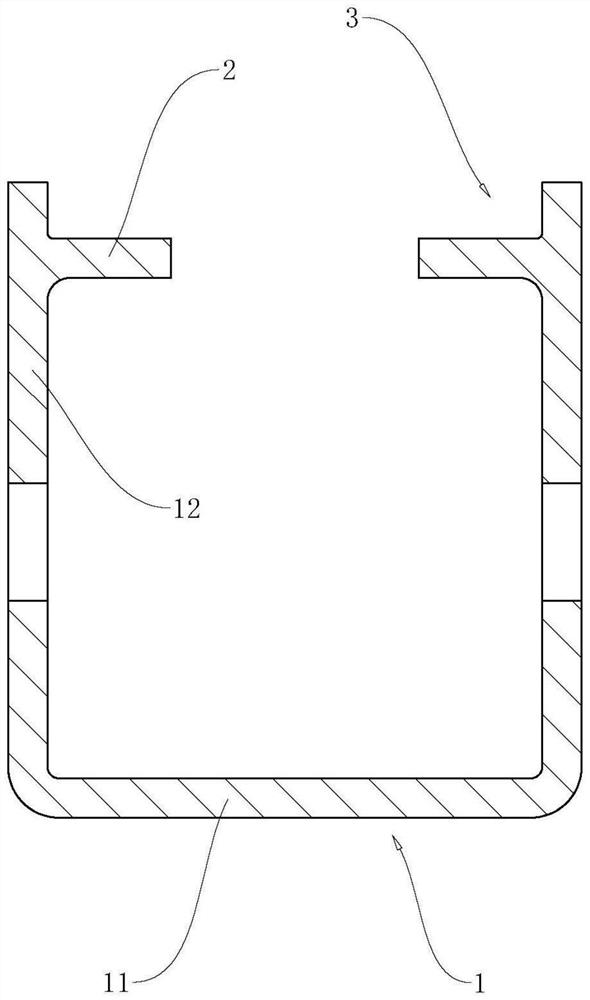

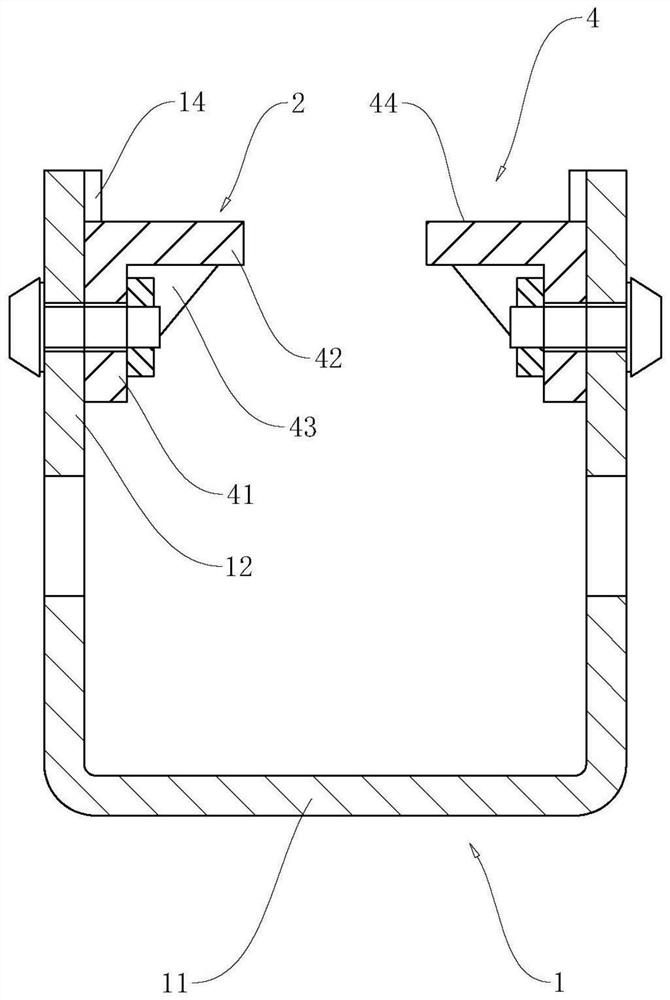

[0041] refer to Figure 1-3 , this kind of track includes a number of first connected track unit assemblies, the track unit assembly includes an integrated track unit 3 and an assembled track unit 4, and the track unit components include a track base 1 and a track panel 2, and the section of the track base 1 is U-shaped and the track base 1 includes a horizontal track base plate 11 and two vertical track side plates 12, the track panel 2 is arranged on the track side plate 12 and is parallel to the track base plate 11, and a yarn is placed on the track panel 2 pipe socket. The track base 1 and the track panel 2 of the integrated track unit 3 are integrally formed, and the track base 1 and the track panel 2 of the assembled track unit 4 realize a detachable fixed connection through a connection structure.

[0042] refer to Figure 1-3 A reinforcement plate 5 is connected between the opposite long sides of the track, and the connection between the reinforcement plate 5 and the...

Embodiment 2

[0048] refer to Figure 4 , the difference between this embodiment and the embodiment is that an installation space 45 with a T-shaped cross-section is formed inside the track panel 2, and lock nuts 46 are pre-embedded in the installation space 45, and a corresponding position of the track side plate 12 is provided for The connecting hole 13 installed on the track panel 2 is provided with a locking screw 47 in the connecting hole 13. The nut of the locking screw 47 is located on the outside of the track side plate 12, and the locking screw 47 and the locking nut 46 cooperate with each other.

[0049] refer to Figure 4 , the connecting holes 13 on the surface of the track side plate 12 are arranged along the length direction of the track side plate 12, and the connecting holes 13 are arranged in multiple rows along the height direction of the track side plate 12, and the connecting holes 13 of each row on the surface of the track side plate 12 are arranged alternately . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com