Continuous copper smelting equipment and two-stage continuous copper smelting process

A copper smelting and process technology, which is applied in the field of continuous copper smelting equipment and two-stage continuous copper smelting process, can solve the problems that the smelting furnace cannot achieve self-heating, the requirement for copper-containing raw materials is high, and the process flow is long, so as to reduce the waiting time for furnace shutdown. time, saving investment and operating costs, and shortening the effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

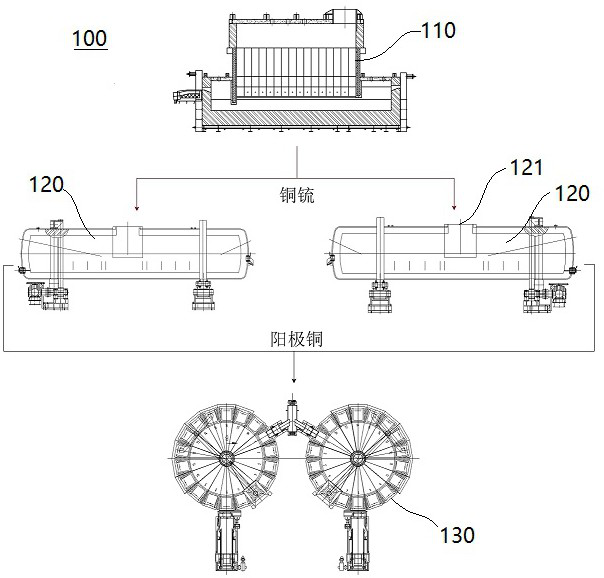

[0027] The following is based on figure 1 The basic structure of the continuous copper smelting plant 100 of the embodiment of the present invention will be described.

[0028] The continuous copper smelting equipment 100 includes a side-blowing smelting furnace 110 and at least two bottom-blowing smelting and refining furnaces.

[0029] The side blowing melting furnace 110 has a melting chamber. The side-blown smelting furnace 110 is also provided with a feeding port for feeding materials, a smelting slag outlet for discharging smelting slag, and a copper matte outlet for discharging copper matte, which communicate with the melting chamber. Copper-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com