Preparation method of immersed aluminum-air battery with negative electrode recovery device

A recovery device and air battery technology, which is applied to the electrodes of primary batteries, battery electrodes, fuel cell half-cells and primary battery half-cells, etc., which can solve the problem of reducing the utilization rate of aluminum electrodes, battery specific capacity, and oxygen reduction reaction. Unable to further progress, restricting the development of aluminum-air batteries and other issues, to achieve the effect of inhibiting hydrogen evolution corrosion, easy industrial application, and ensuring continuous discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

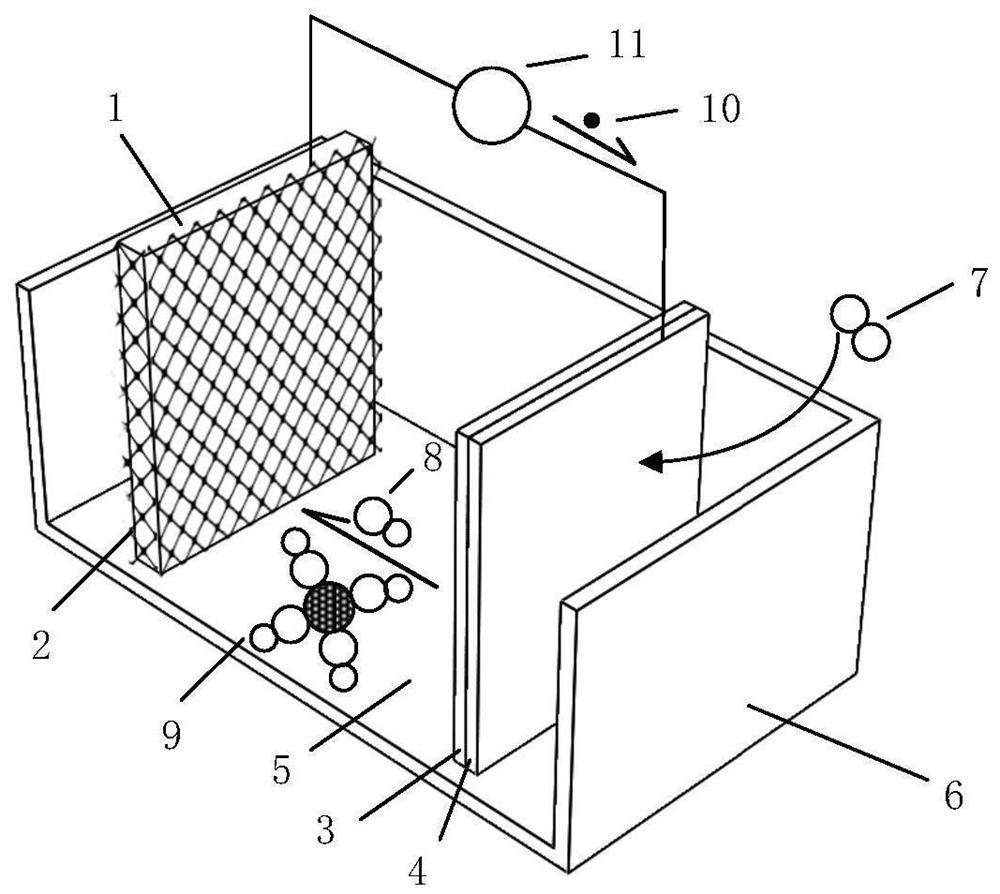

[0037] This implementation involves the production of a battery with a negative electrode recovery device with a pure aluminum negative electrode-4mol / L sodium hydroxide & 0.3mol / L zinc oxide electrolyte-new air positive electrode.

[0038] Prepare a solution with a concentration of sodium hydroxide of 4 mol / L and a concentration of zinc oxide of 0.3 mol / L as electrolyte 5; mash 50 mg of manganese dioxide, 88 mg of cobalt nitrate and 40 mg of carbon nanotubes and add a mixture of 45 mL of perfluorosulfur In the mixed solution of acid type polymer solution, 600mL isopropanol and 350mL deionized water, the black slurry was obtained by ultrasonic dispersion; the obtained black slurry was evenly added dropwise to ultrasonic cleaning with acetone, ethanol and deionized water respectively. After 30 minutes on the dust-free carbon paper, after drying at 70°C for 5 hours, the positive catalyst 3 was obtained; the obtained catalyst 3 was placed on the surface of the foamed nickel 4, and...

Embodiment 2

[0040] This implementation involves the production of a pure aluminum negative electrode-6mol / L potassium hydroxide & 0.5mol / L zinc oxide electrolyte-new air positive electrode with a negative electrode recovery device.

[0041] Prepare a solution with a concentration of potassium hydroxide of 6 mol / L and a concentration of zinc oxide of 0.5 mol / L as electrolyte 5; mash 55 mg of manganese dioxide, 82 mg of cobalt nitrate and 45 mg of carbon nanotubes and add 50 mL of perfluorosulfur In the mixed solution of acid type polymer solution, 620mL isopropanol and 370mL deionized water, a black slurry was obtained by ultrasonic dispersion; the obtained black slurry was evenly added dropwise to ultrasonic cleaning with acetone, ethanol and deionized water respectively. After 30 minutes on the dust-free carbon paper, after drying at 65°C for 5 hours, the positive catalyst 3 was obtained; the obtained catalyst 3 was placed on the surface of the nickel foam 4, and pressed with a roller pre...

Embodiment 3

[0043] This implementation involves the production of a battery with a negative electrode recovery device with a pure aluminum negative electrode-6mol / L potassium hydroxide & 0.5mol / L zinc oxide electrolyte-water-flooded faulty positive electrode.

[0044] Prepare a solution with a concentration of potassium hydroxide of 6 mol / L and a concentration of zinc oxide of 0.5 mol / L as the electrolyte 5; use a 1.2 mm thick air electrode that has been flooded and has a salt-emission failure as the positive electrode; use a pore size of 1.5× The 1.5mm wire mesh is processed into a hollow column as the negative electrode recovery device 2; pure aluminum with a purity of 99.6% is selected as the negative electrode 1; the resulting electrolyte 5, positive electrode, negative electrode recovery device 2, and negative electrode 1 are assembled into a semi-open cube type aluminum-air battery, conduct 20mA / cm2 The discharge test under constant current density worked stably for 5.3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com