Expansion kettles, cooling systems and cars

A technology of expansion kettle and cooling system, which is applied in the cooling of engines, machines/engines, and mechanical equipment, etc., can solve the problems of a large number of parts in the cooling system, unfavorable lightweight of automobiles, and heavy weight, and reduce the number of parts and components. and the effect of total weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

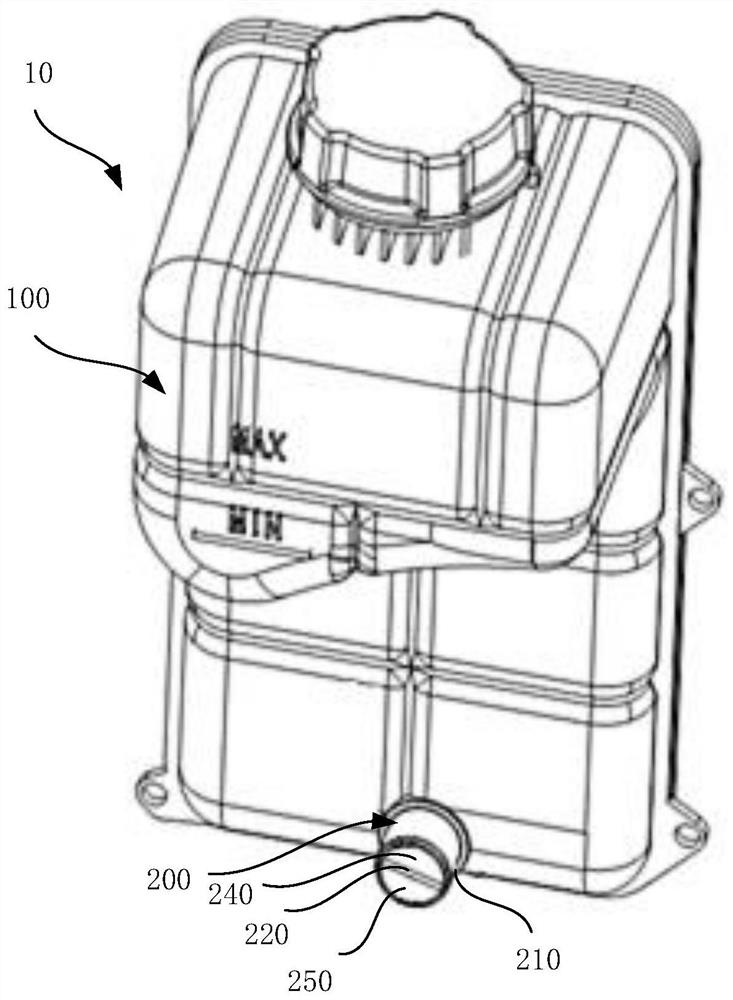

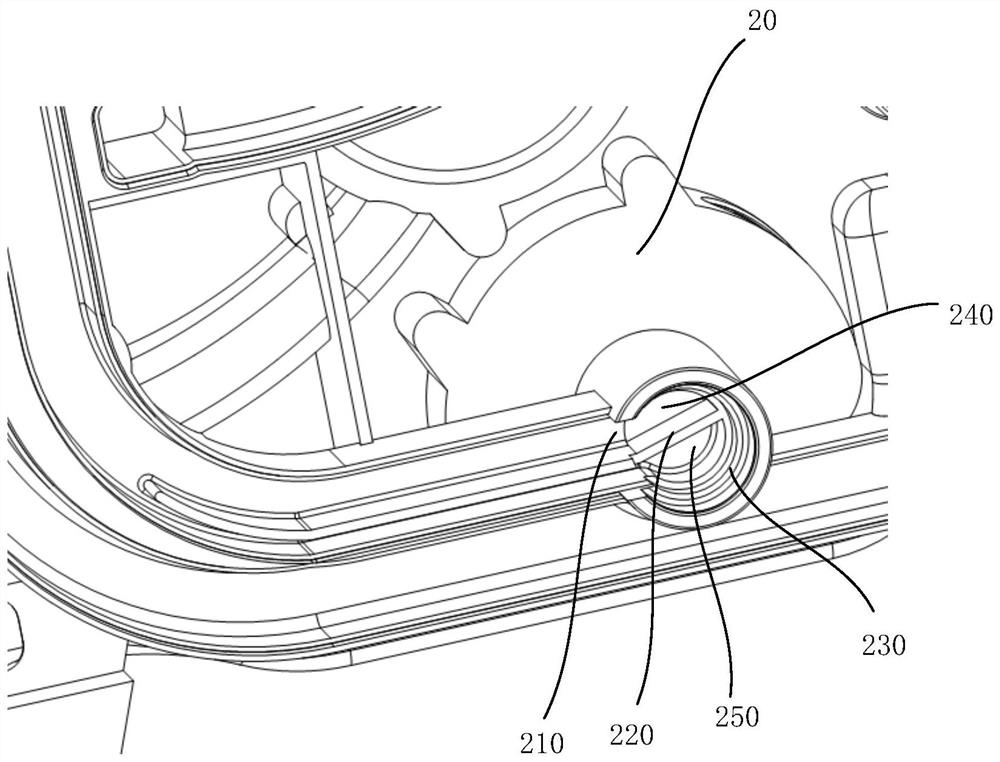

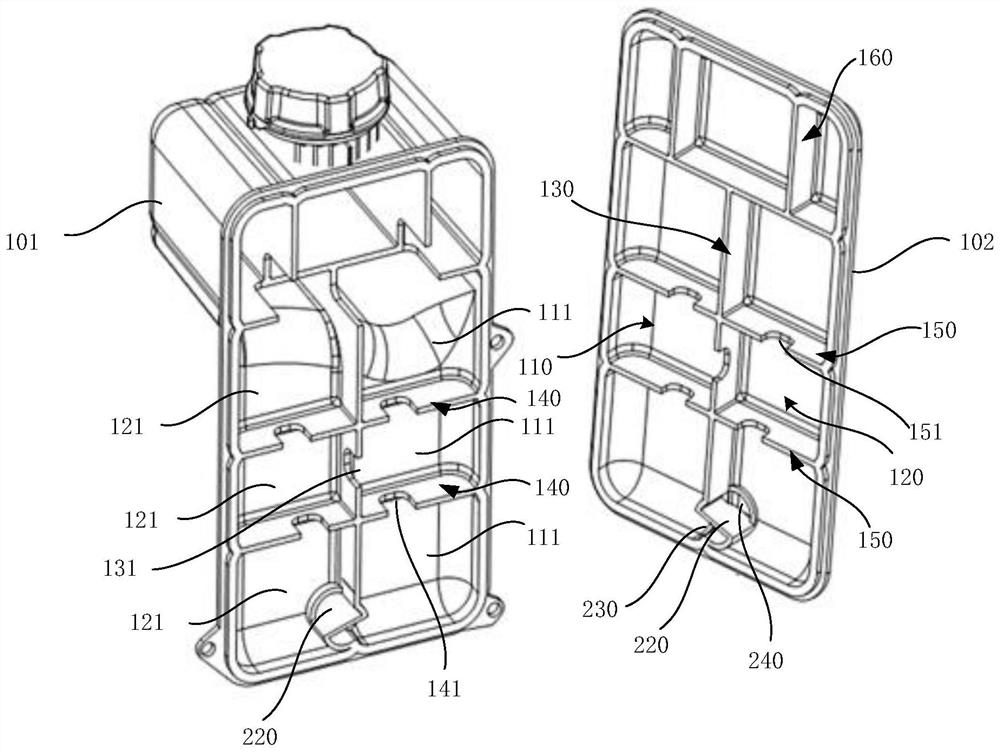

[0044] figure 1 A schematic structural diagram of an expansion kettle provided by an embodiment of the present application; figure 2 A schematic diagram of the connection structure between the pipeline and other equipment provided by an embodiment of the application; image 3 An exploded view of an expansion kettle provided for an embodiment of the present application; Figure 4 The flow direction diagram of the mixed liquid in the expansion kettle provided by an embodiment of the present application.

[0045] Please refer to Figure 1-Figure 4 , the present embodiment provides an expansion kettle 10, including a kettle body 100, a first partition 130 is arranged inside the kettle body 100, and the first partition 130 divides the interior of the kettle body 100 into a first chamber 110 and a second chamber In the chamber 120 , the first partition 130 is provided with a first through hole 131 communicating with the first chamber 110 and the second chamber 120 .

[0046] Spec...

Embodiment 2

[0062] Figure 5 A schematic structural diagram of a cooling system provided by an embodiment of the present application.

[0063] Please refer to Figure 5 , the present embodiment provides a cooling system, including a water pump 20, a component to be cooled 30, a heat exchanger 40, and any expansion kettle 10 as above. The water pump 20, the component to be cooled 30, the heat exchanger 40 and the expansion kettle 10 pass through The channels are connected in sequence, wherein the heat exchanger 40 is connected to the mixed liquid inlet of the expansion kettle 10 , and the second channel of the expansion kettle 10 is connected to the water pump 20 .

[0064] Specifically, the component to be cooled 30 in this embodiment may be an engine, a motor, or a battery pack. The water pump 20 is used to provide circulation power for the entire system. Under the action of the water pump 20 , the mixture of cooling liquid and gas can circulate along the pipeline in the system to redu...

Embodiment 3

[0066] This embodiment provides an automobile, including the cooling system in Embodiment 2 above.

[0067] Specifically, the cooling system in this embodiment may be located in the engine compartment of the vehicle or in the space between the chassis and the vehicle body. Because the automobile of this embodiment has adopted the cooling system of the above-mentioned embodiment two, there is no need to arrange a special liquid-gas separator in the cooling system, which helps to reduce the number of parts and the total weight in the cooling system, and also reduces the cooling system temperature. The number of pipes in the car reduces the cost and is conducive to the lightweight of the car.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com