Gas-liquid separation device with built-in heat exchanger, and gas-liquid separation method

A gas-liquid separation device and technology for gas-liquid separation, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high production cost, only separation of gas and water, and no cooling function, etc. To achieve the effect of low manufacturing and use costs, good separation and cooling effects, and conducive to popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

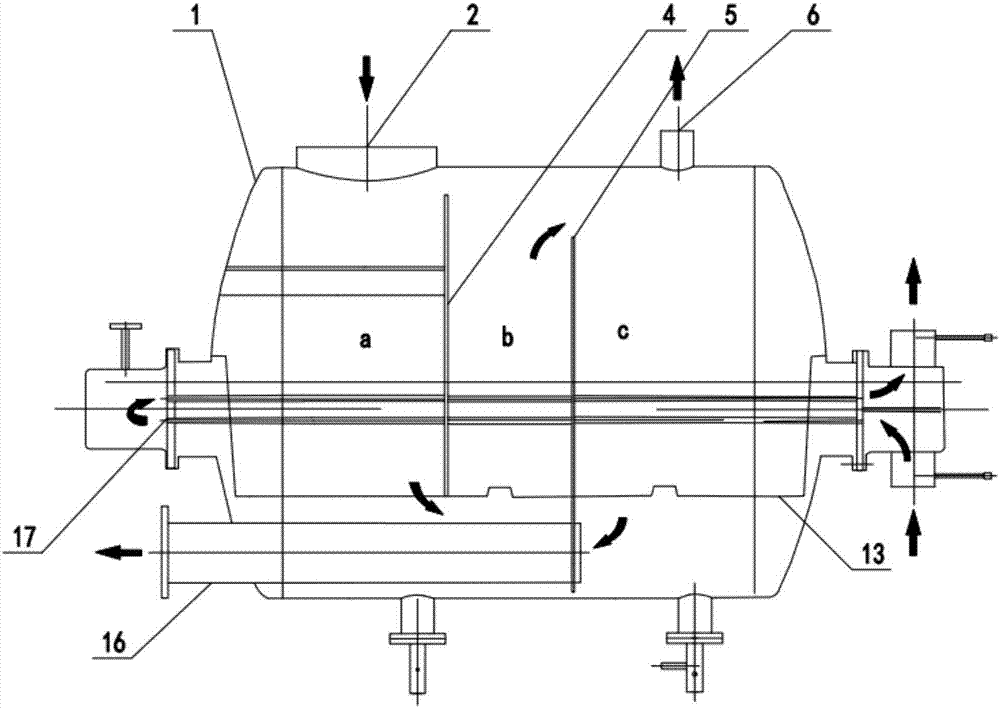

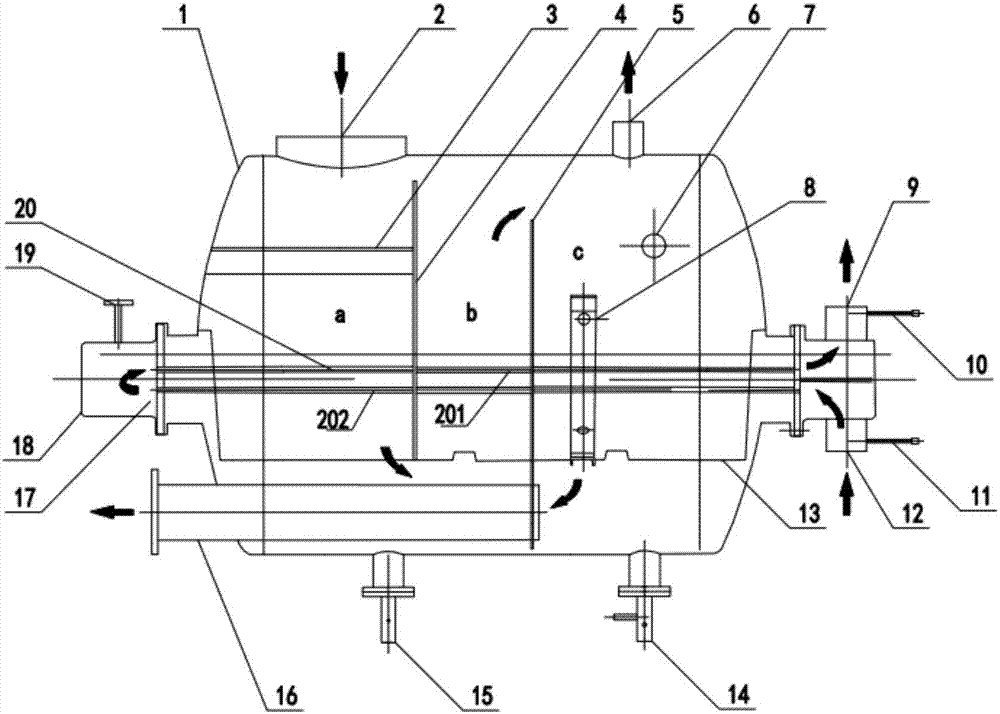

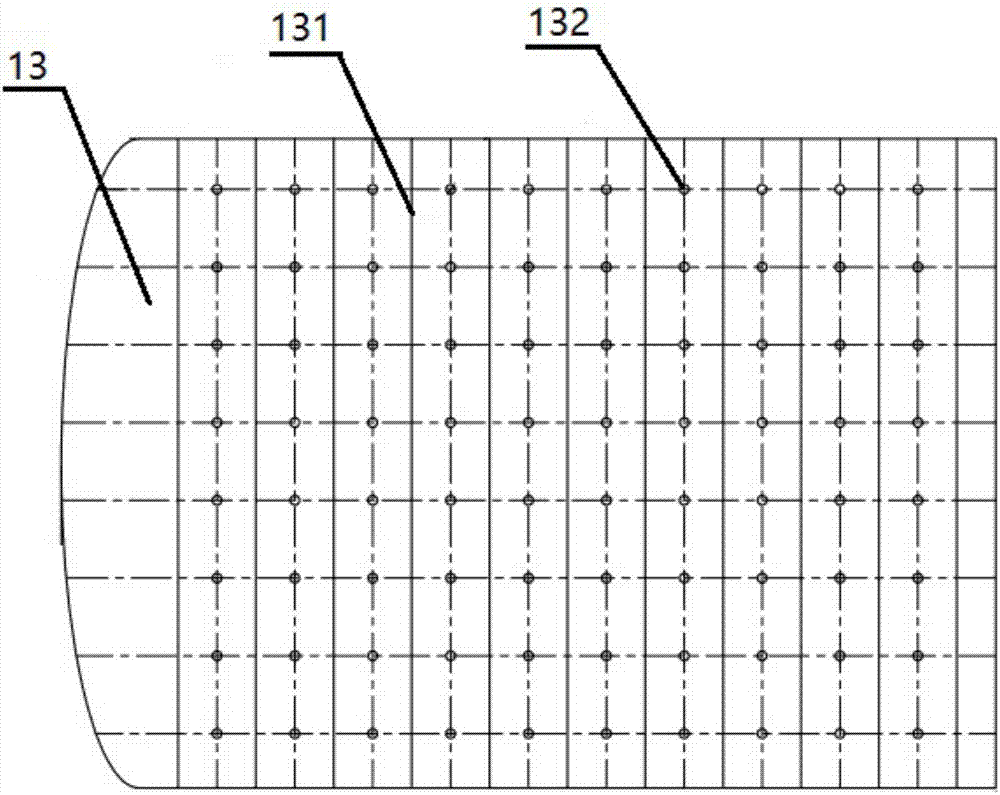

[0045] Such as figure 1 As shown, the present invention provides a gas-liquid separation device with a built-in heat exchanger, including a housing 1, the top of the housing 1 is provided with a gas-liquid mixture inlet 2, and an air outlet 6, wherein: inside the housing 1, there are horizontally arranged The tubular heat exchanger 17 that runs through the left and right side walls of the housing 1 is used to exchange heat for the gas-liquid mixture entering the housing 1. The lower part of the tubular heat exchanger 17 is connected to the The area between the bottom of the housing 1 is also provided with a deceleration orifice plate 13 laterally, which is used to reduce the gas-liquid mixture liquid passing through the deceleration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com