Oil injector

A technology of fuel injectors and actuators, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., to achieve precise control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

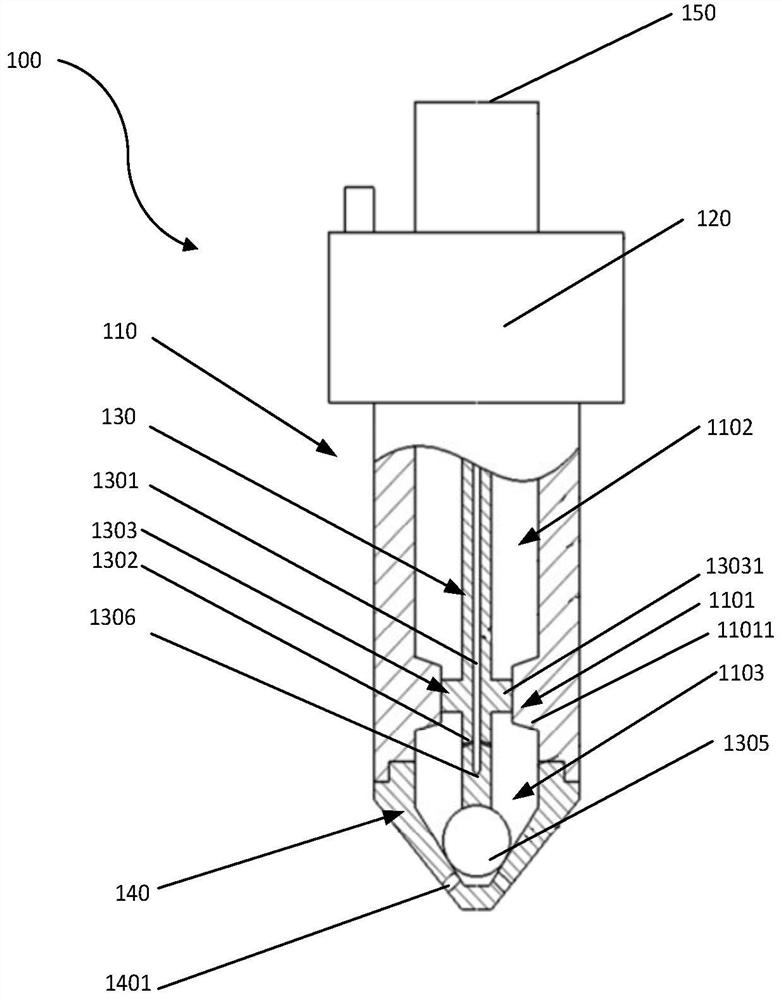

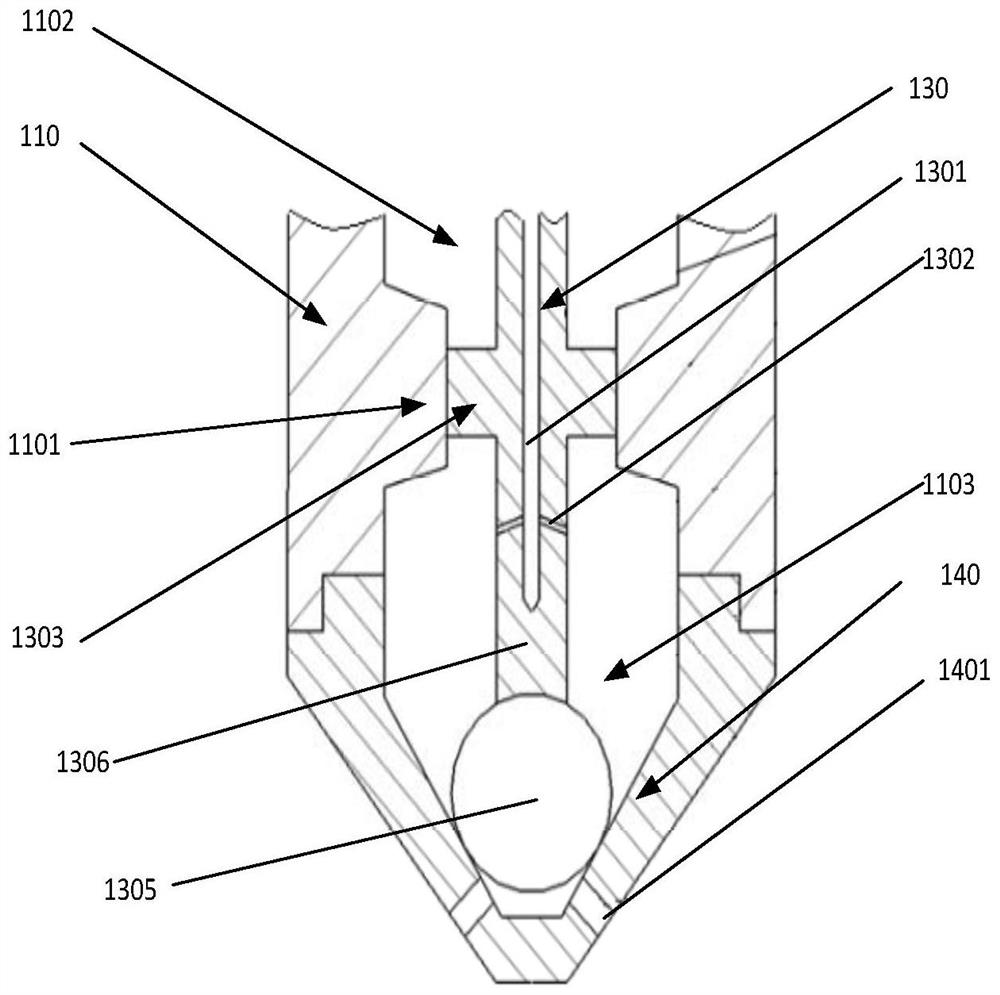

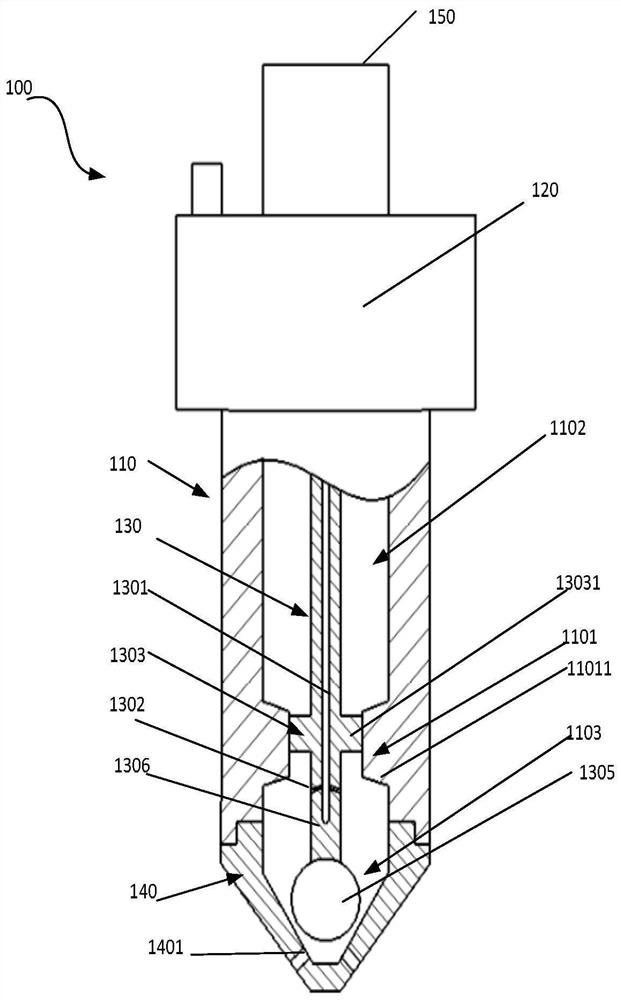

[0062] In order to solve the problem that the electronically controlled fuel injector in the prior art can only realize the flow control in the large flow area, such as Figure 1a-Figure 3 As shown, the embodiment of this embodiment discloses a fuel injector 100, including an actuator 120, a fuel injector body 110, a moving closing body 130, and a valve seat 140; wherein, the fuel injector body 110 has a hollow structure for Accommodates a mobile enclosure 130 . Further, one end of the injector body 110 is connected to one end of the valve seat 140 , the injector body 110 and the inner chamber of the valve seat 140 together form a valve chamber, and the movable closing body 130 can slide in the valve chamber.

[0063] Wherein, the moving closing body 130 includes a valve stem 1306 and a movable restrictor 1303 arranged on the valve stem 1306, and also includes a ball core 1305 arranged on the end face of the valve stem 1306 close to the valve seat 140, and the valve stem 1306 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com