Integrated ultrasonic thickness gauge for taking coupling agent in pressing mode

An ultrasonic and thickness gauge technology, applied in the detection field, can solve the problems of uneven coating, cumbersome operation, waste, etc., and achieve the effects of improving work accuracy, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

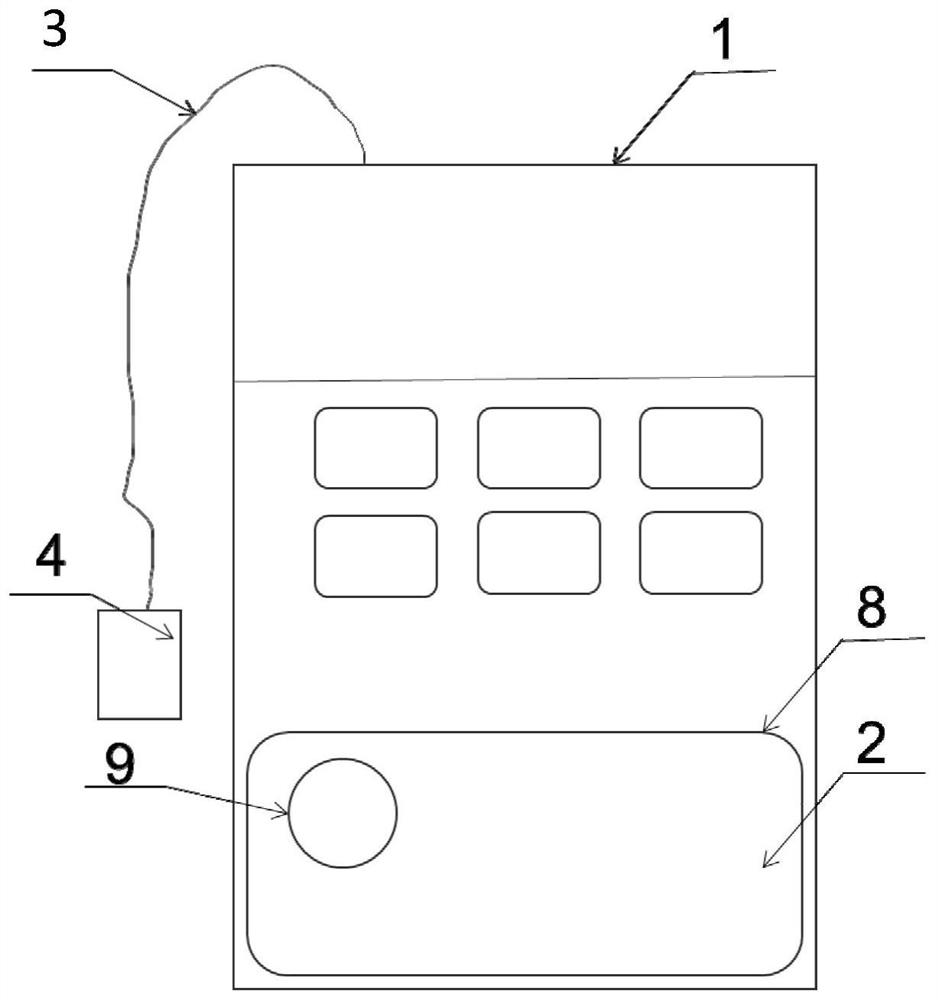

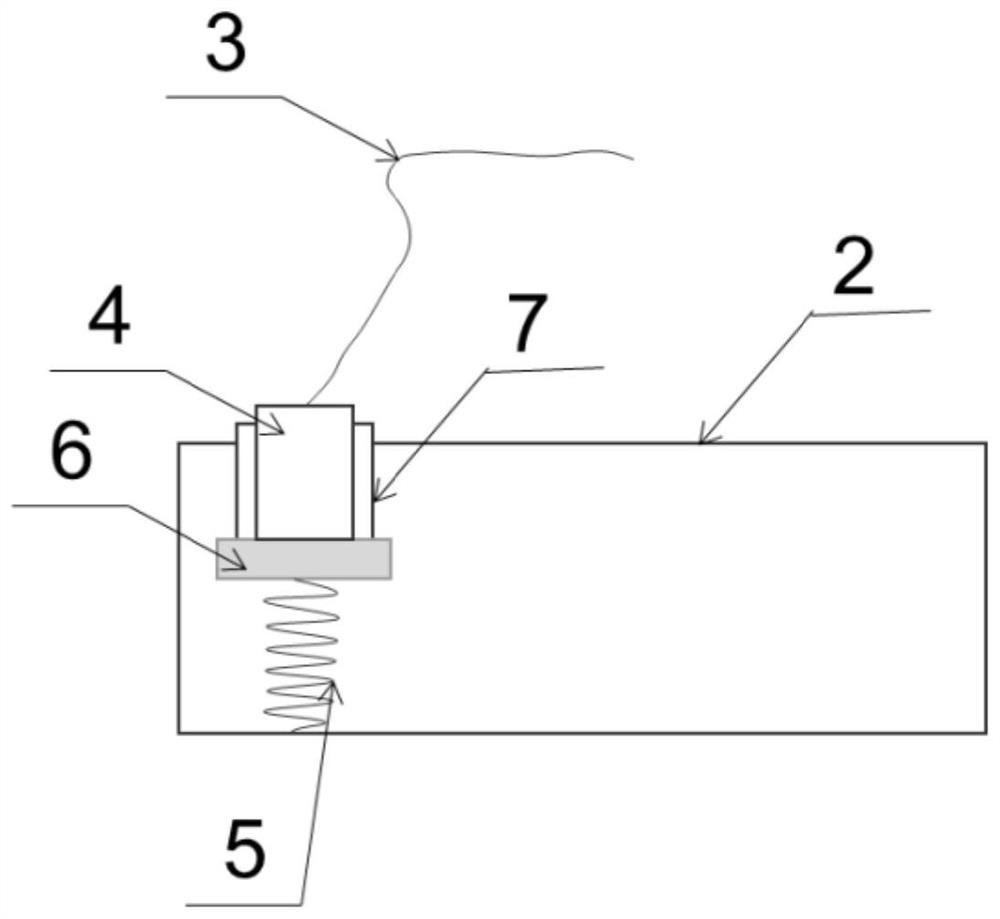

[0024] Such as figure 1 with figure 2 As shown, an integrated ultrasonic thickness gauge adopting a pressing type to take coupling agent according to the present invention includes an ultrasonic thickness gauge body 1, a built-in liquid storage box 2, a wire 3, an ultrasonic probe 4, a spring, 5, and a metal tester. Block 6, cylindrical groove 7, large end cap 8 and small end cap 9.

[0025] The upper part of the body 1 of the ultrasonic thickness gauge is connected with a wire 3 , and the other end of the wire 3 is connected with an ultrasonic probe 4 . A built-in liquid storage box 2 is fixed on the lower part of the body 1 of the ultrasonic thickness gauge. The total height of the built-in liquid storage box 2 is 30 mm to 40 mm, which is slightly higher than the surface of the body 1 of the ultrasonic thickness gauge. A la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com