Fuel tank for direct liquid fuel battery system with self-closing interface

A liquid fuel cell and fuel tank technology, applied in the direction of fuel cell additives, etc., can solve the problems of incomplete fuel follow-up, fuel supply cut-off, etc., and achieve the effect of avoiding system shutdown and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

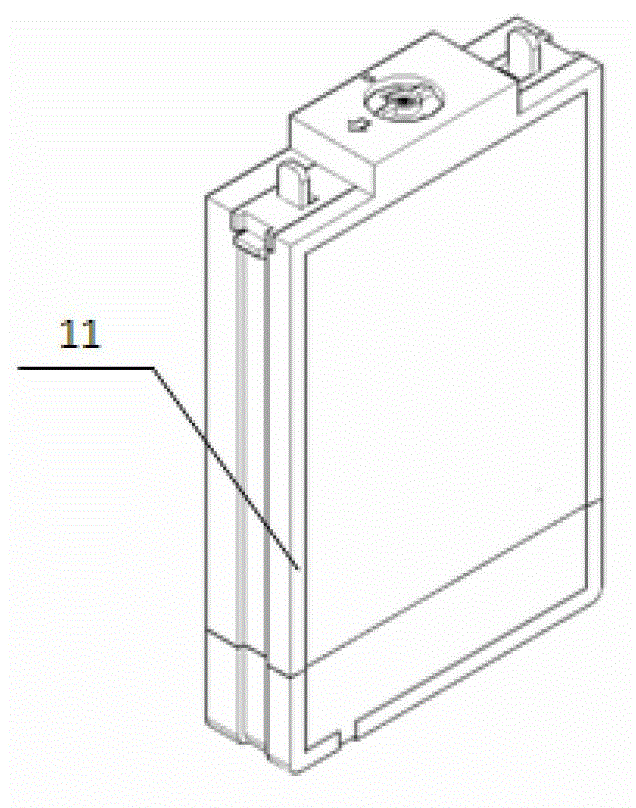

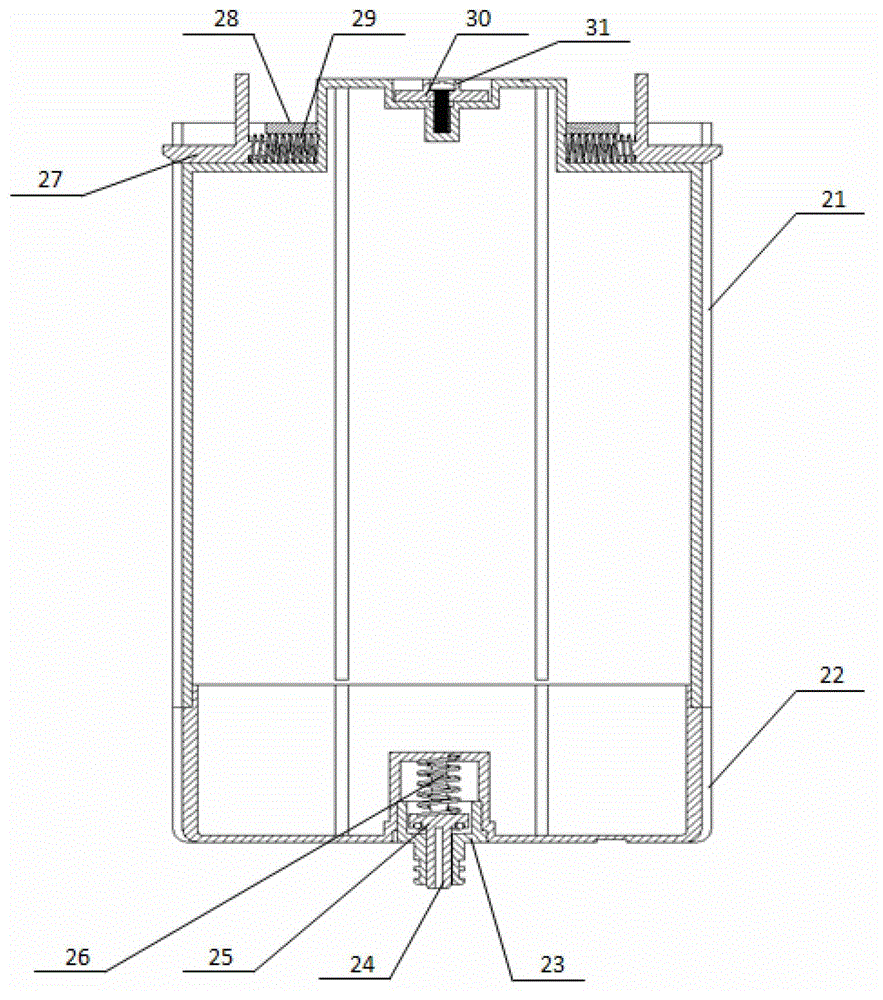

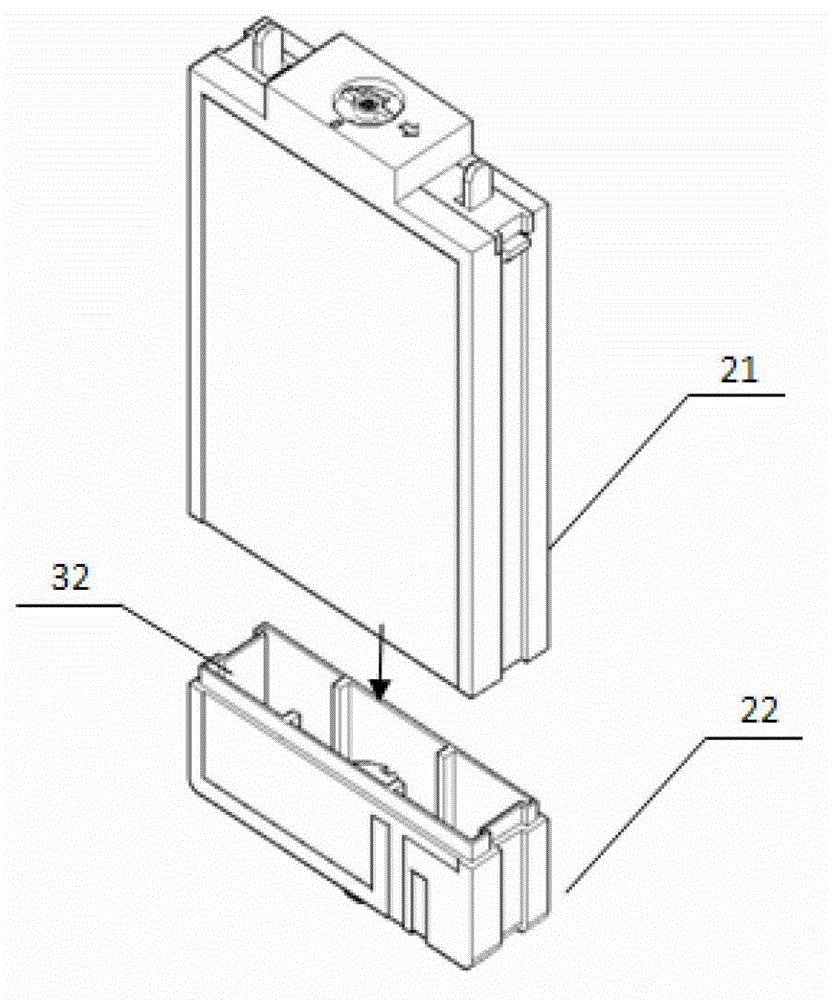

[0031] Such as figure 2 , image 3 and Image 6 As shown, the present invention includes a fuel tank body, a Kafun mechanism, a screw seal cap 30 and a self-closing interface, wherein the fuel tank body is a flat structure, including an upper fuel tank body 21 and a lower fuel tank body 22, and the upper fuel tank body 21 It is positioned with the lower fuel tank body 22 through the seam 32, and is connected by ultrasonic welding technology or bonded and sealed by bonding technology, and the adhesive used can be chloroform or acetone. The fuel tank is made of methanol-resistant PC (polycarbonate) or PEI (polyetherimide). The upper end of the upper fuel tank body 21 is respectively provided with a screw sealing cover 30 and a Kafun mechanism connected with an external mounting body and restricting the movement of the fuel tank body. The self-closing interface is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com