Patents

Literature

43 results about "Ultrasonic pachymeter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

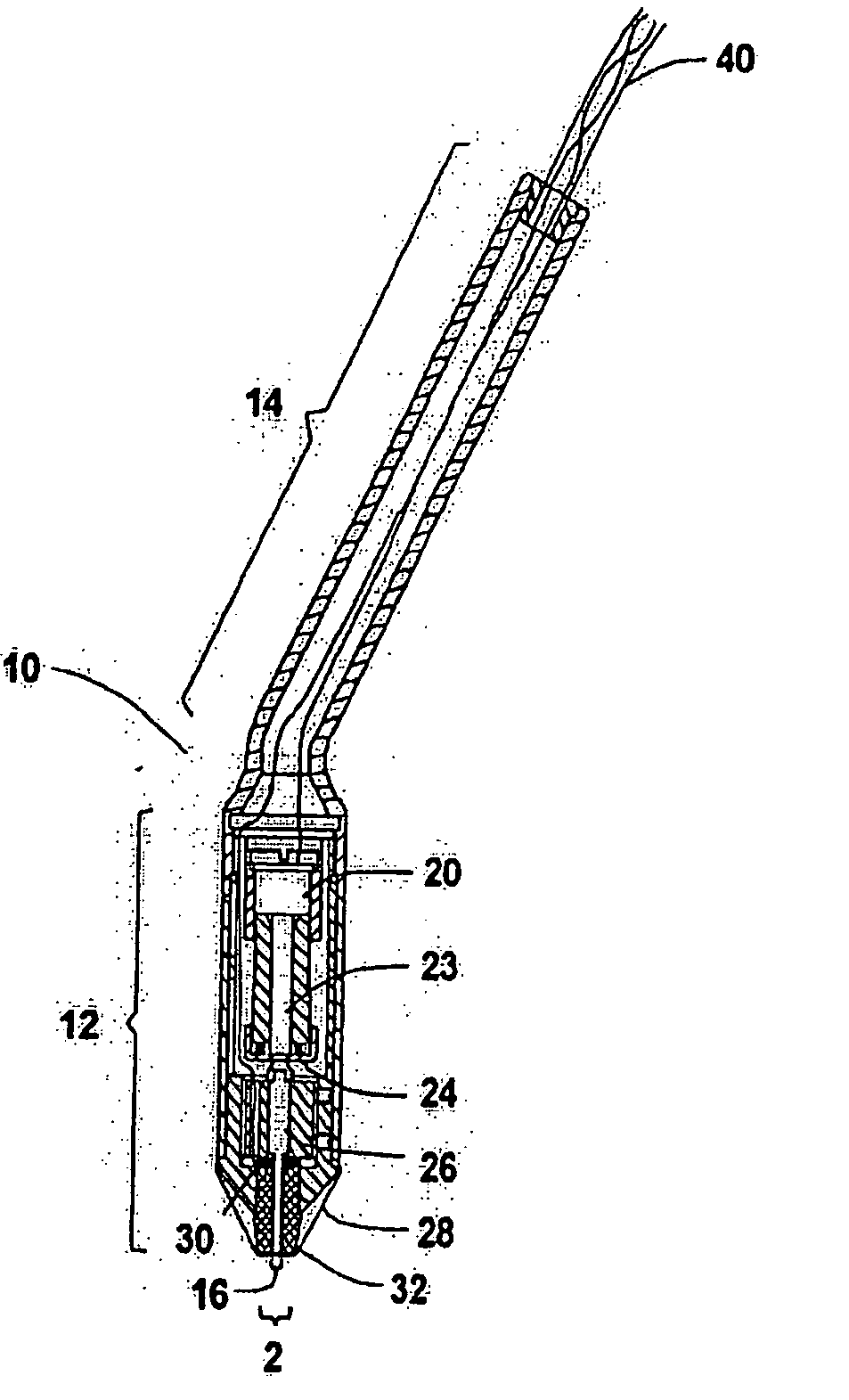

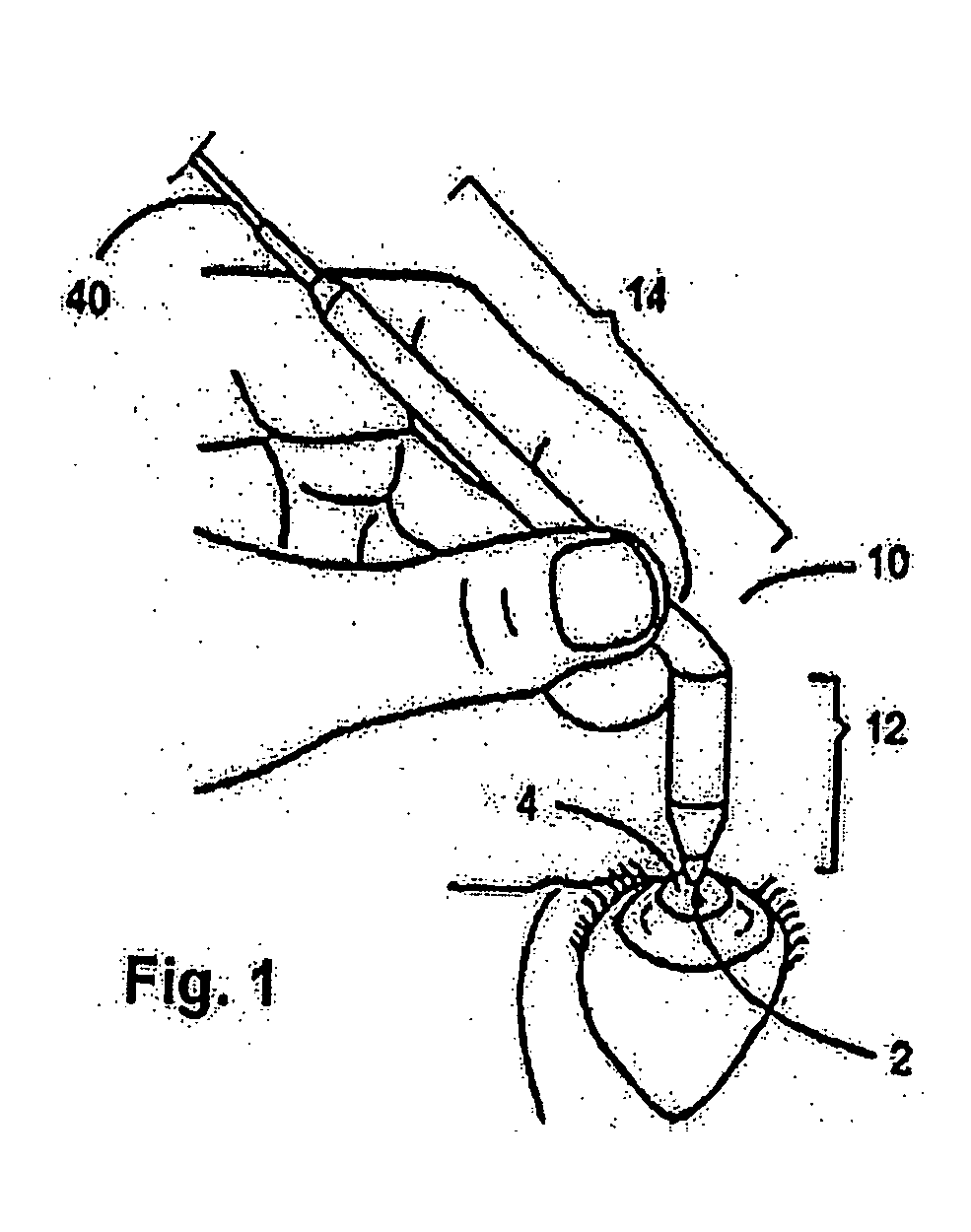

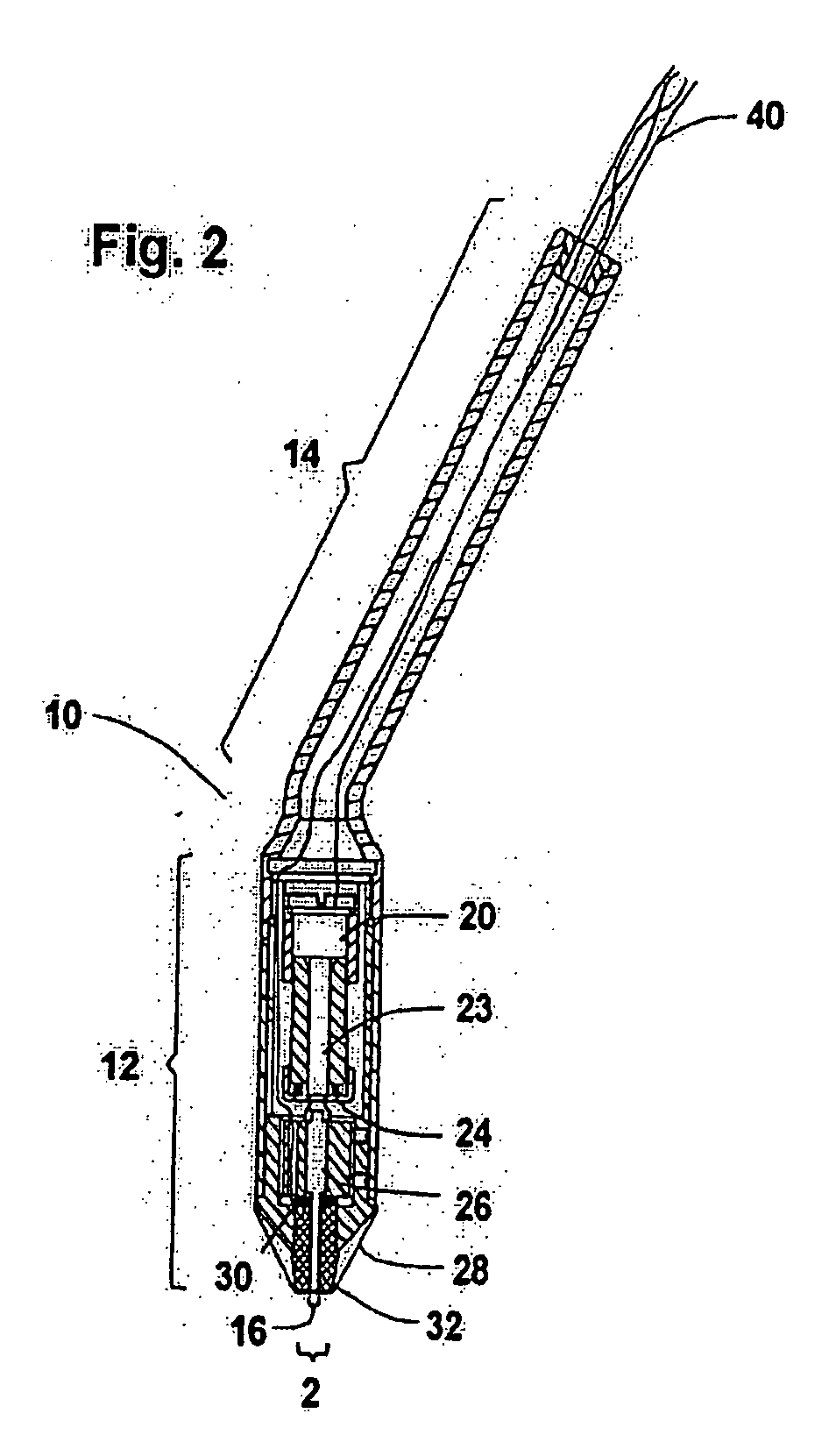

Tonometer-pachymeter apparatus for measurement of intraocular pressure

ActiveUS20070123769A1Easy to useAccurate pressureInfrasonic diagnosticsSonic diagnosticsApplanation tonometerMembrane stretch

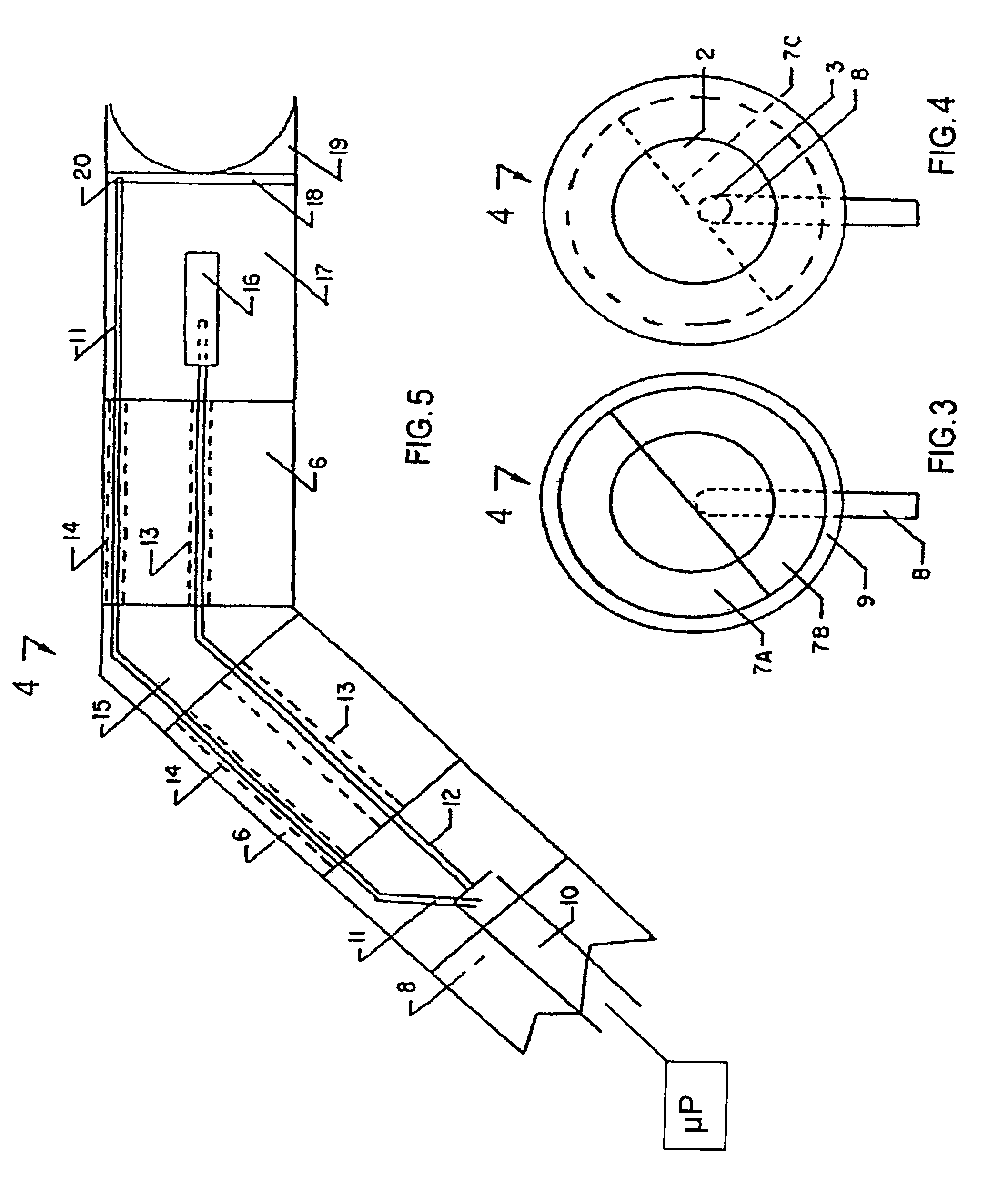

An apparatus for determining intraocular pressure includes a transducer assembly containing an applanation tonometer for the determination of a cornea applanation pressure and an ultrasonic pachymeter to determine the thickness of the cornea at the site of applanation. The assembly has a tip end which includes an applanation surface and an ultrasonic coupler surface, and an end cap membrane holder is adapted to fit over the tip end of the transducer assembly and hold a thin film membrane stretched over the applanation and ultrasonic coupler surfaces. The transducer assembly also has a detector for detecting the presence or absence of the end cap membrane holder, the detector may generate a signal to disable movement of the transducer assembly if the end cap is not detected.

Owner:EMOTION PACIFICA

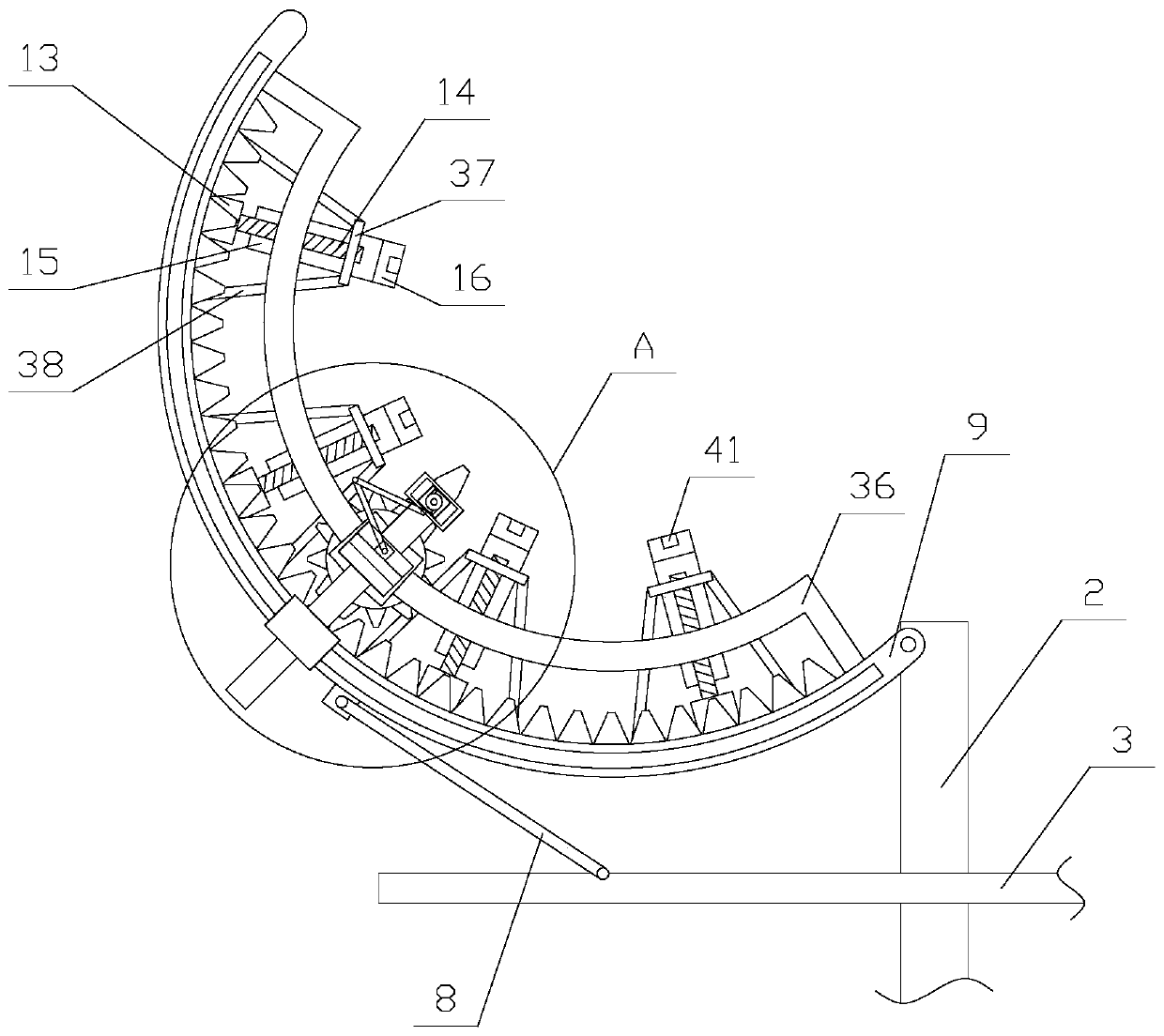

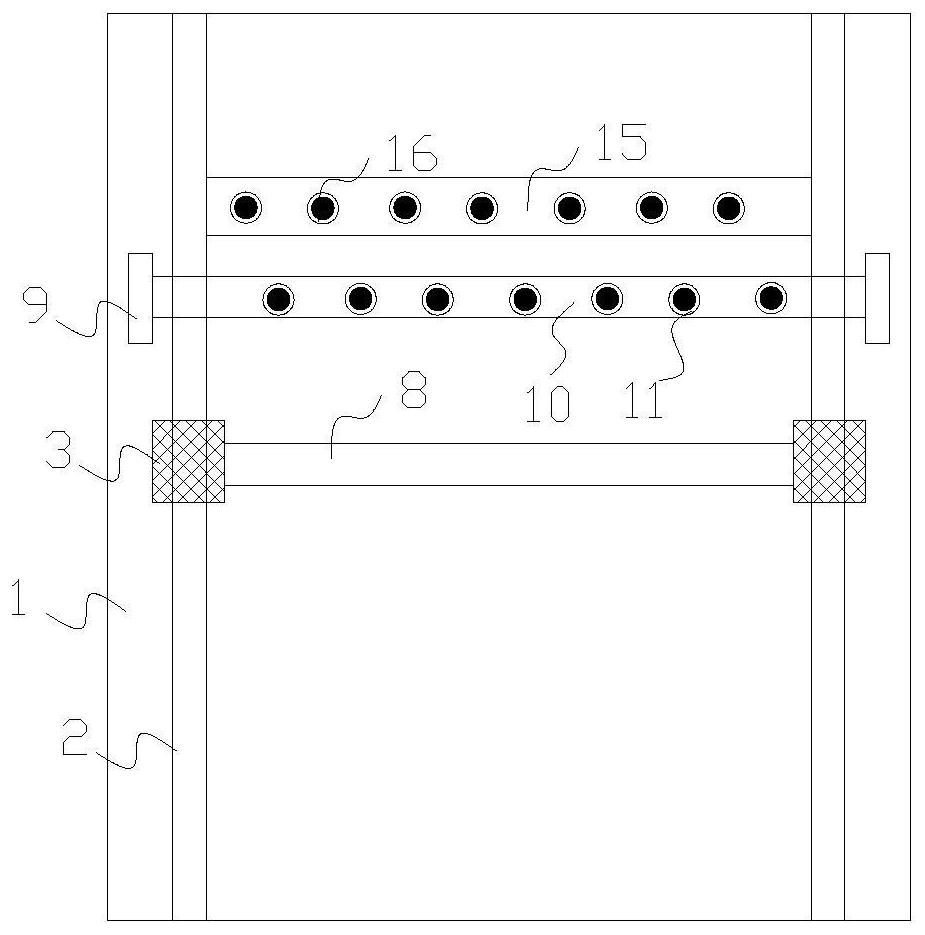

Quick positioned detecting method for thickness size of variable thickness part and auxiliary detecting device

ActiveCN102980540ASolve efficiency problemsSolve the errorUsing subsonic/sonic/ultrasonic vibration meansVariable thicknessUltrasonic pachymeter

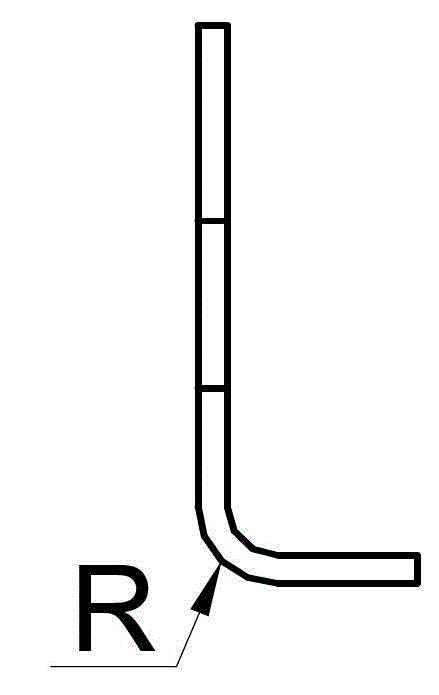

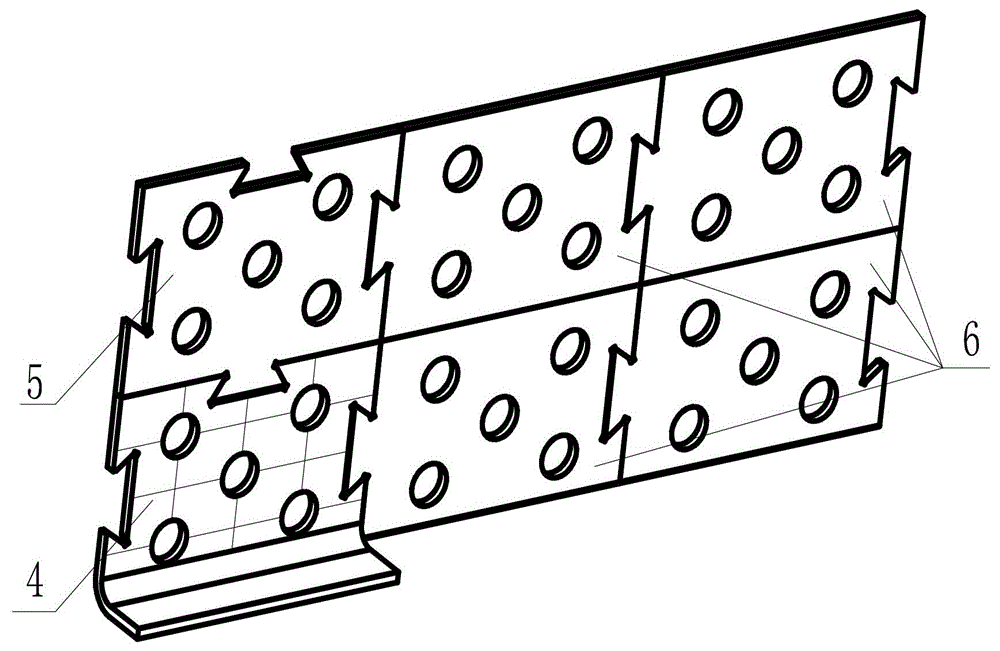

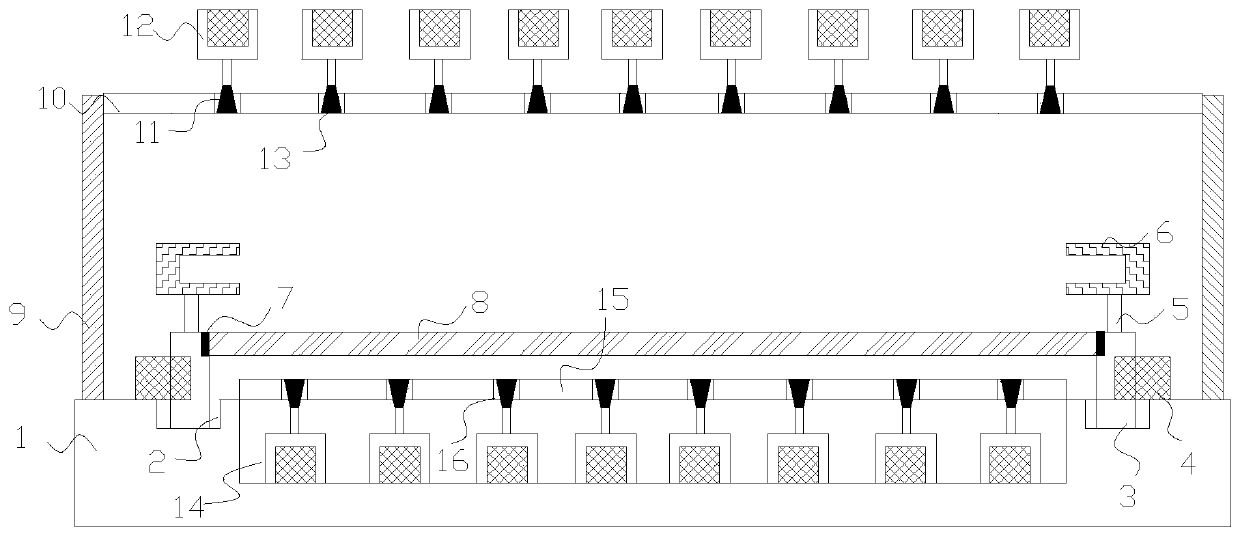

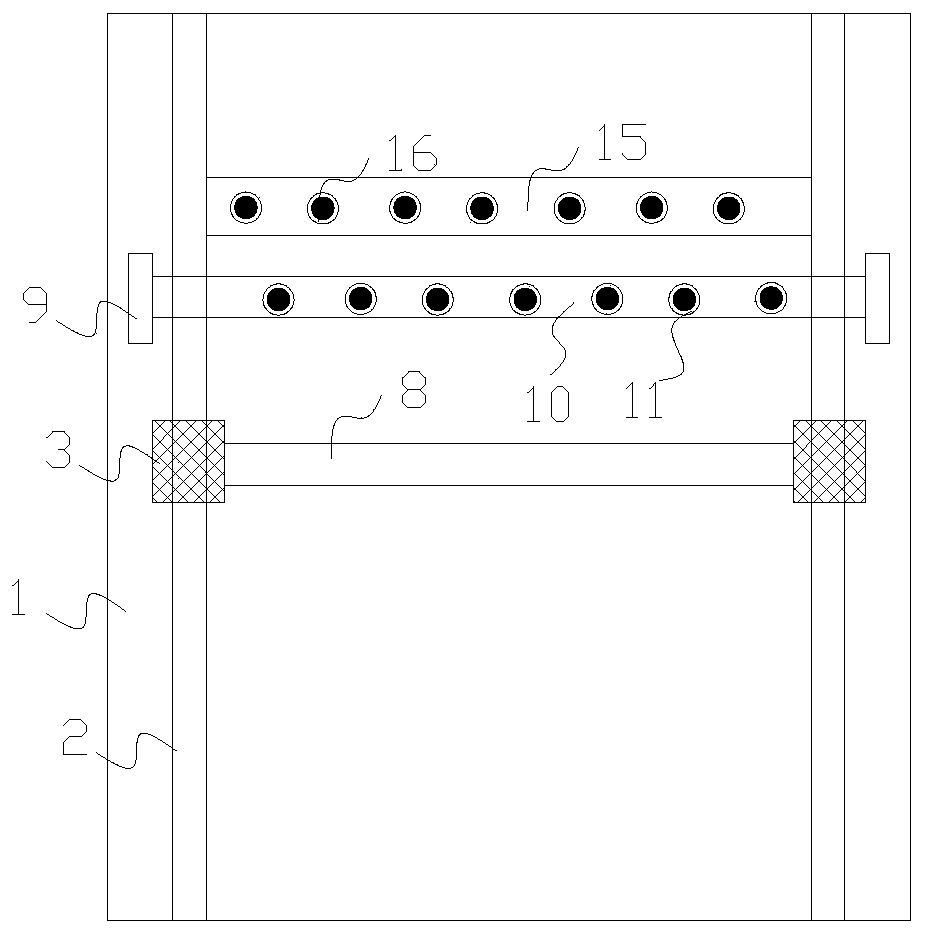

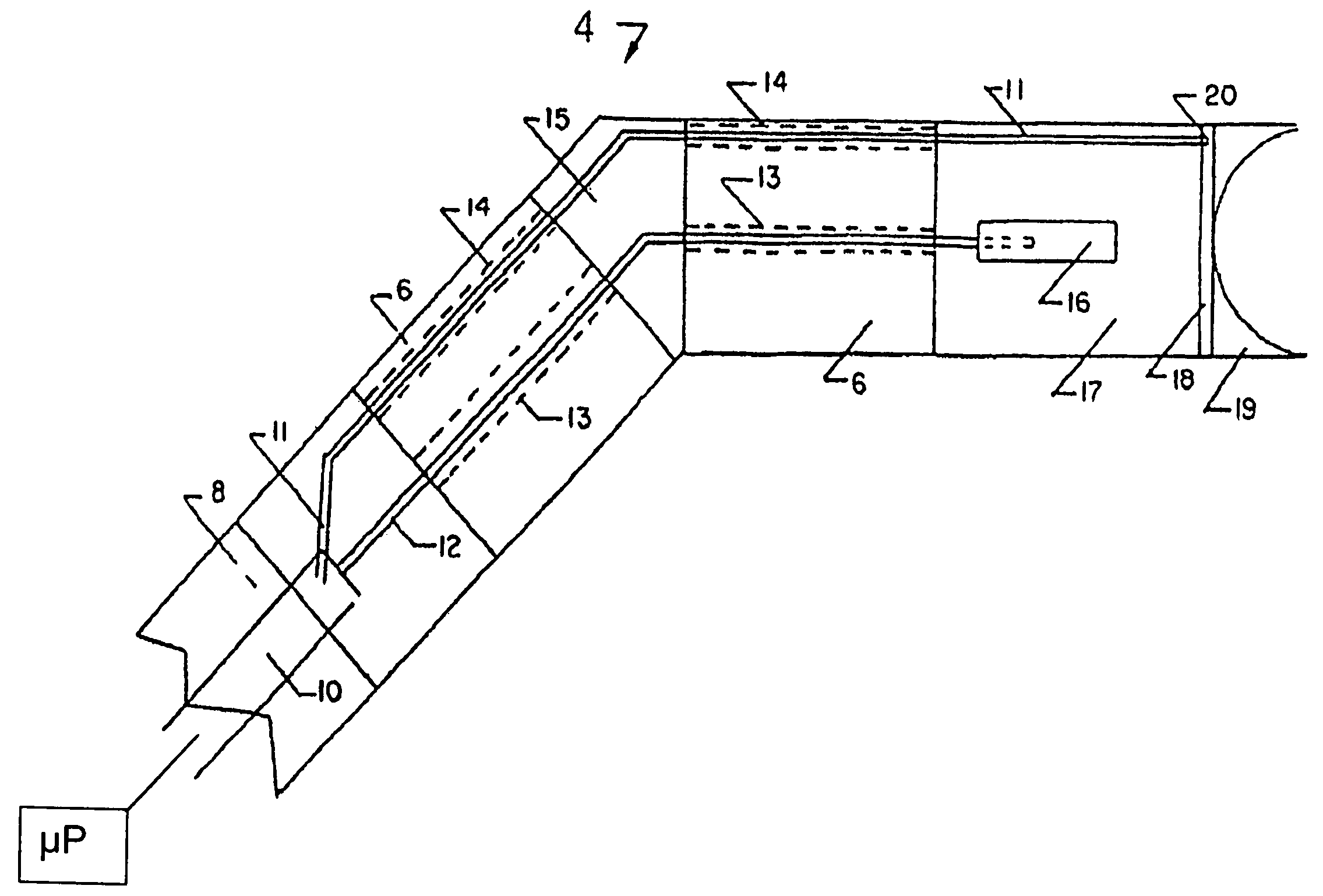

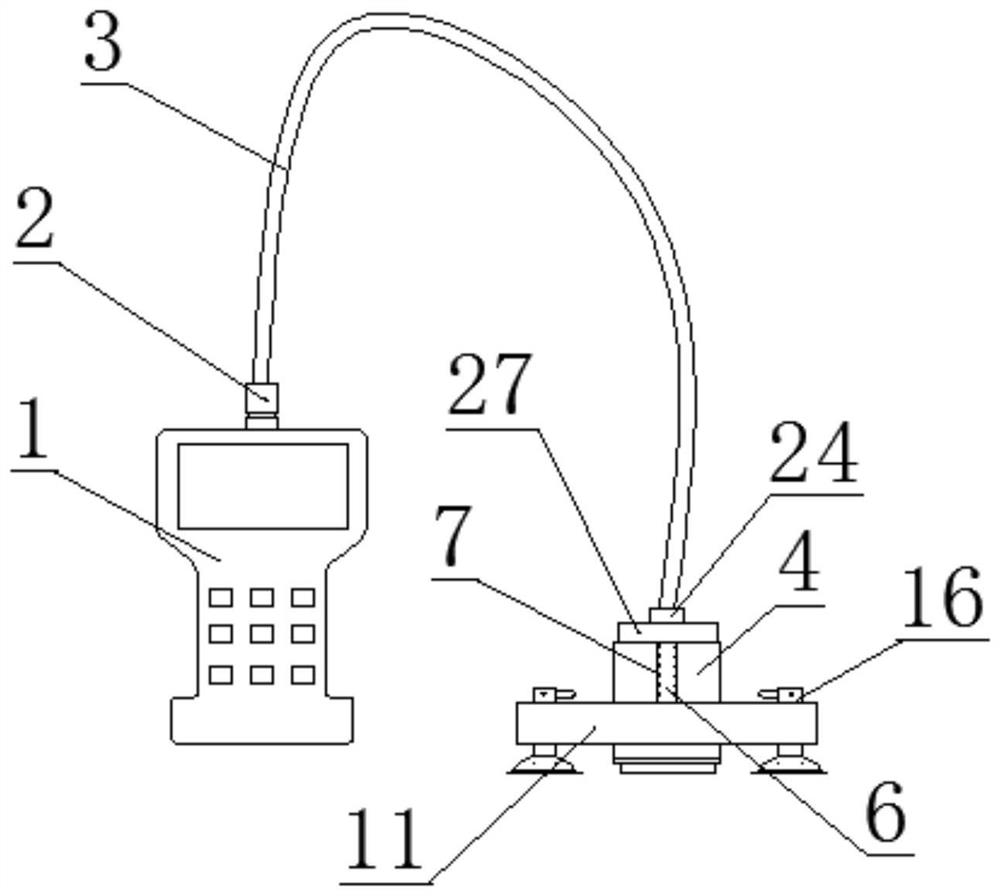

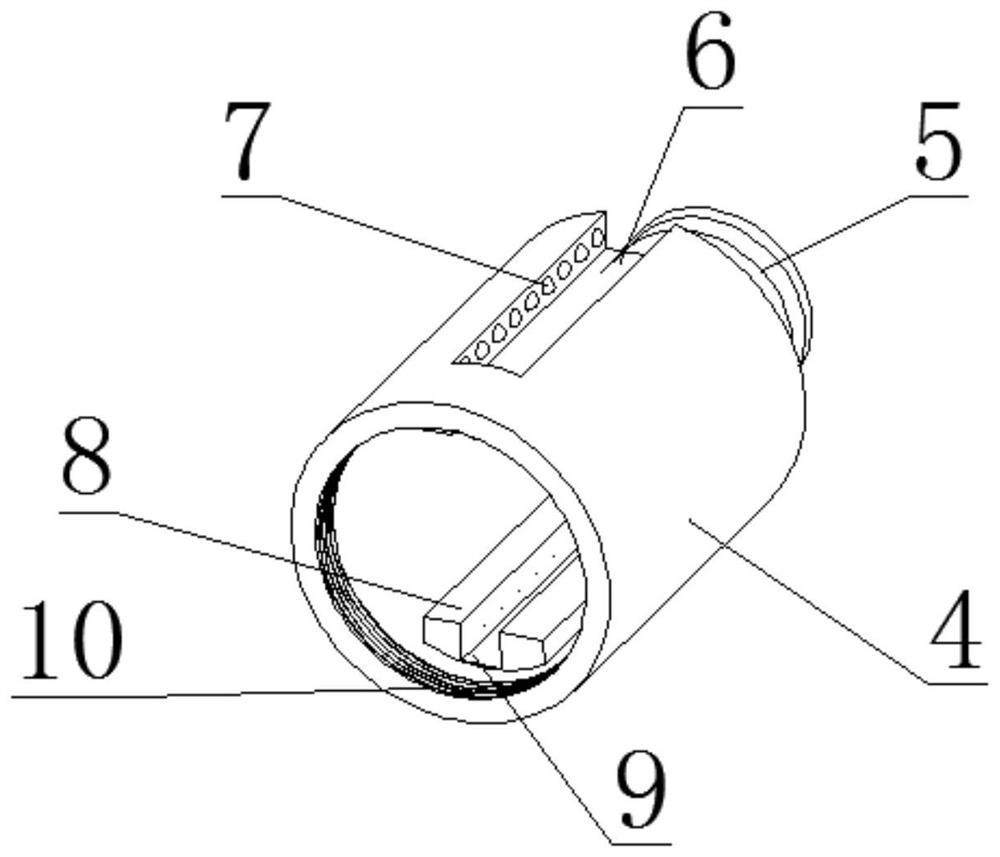

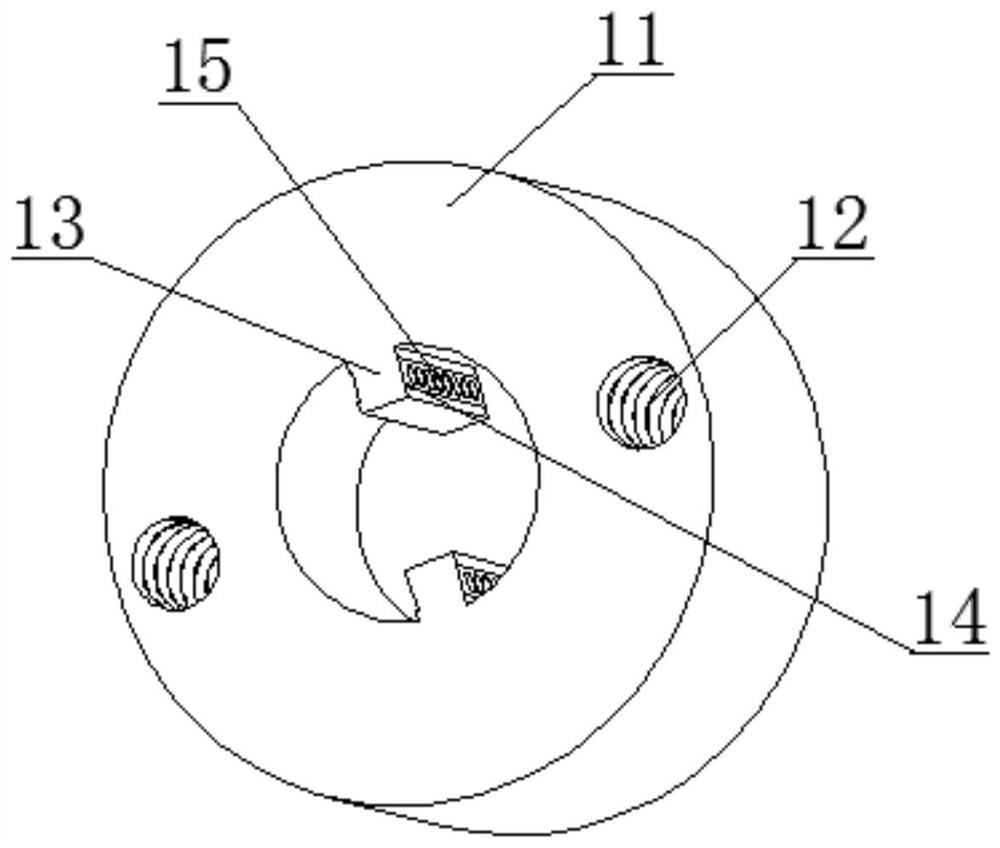

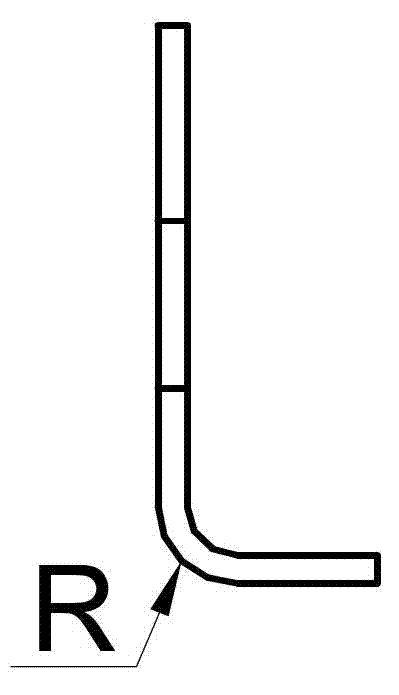

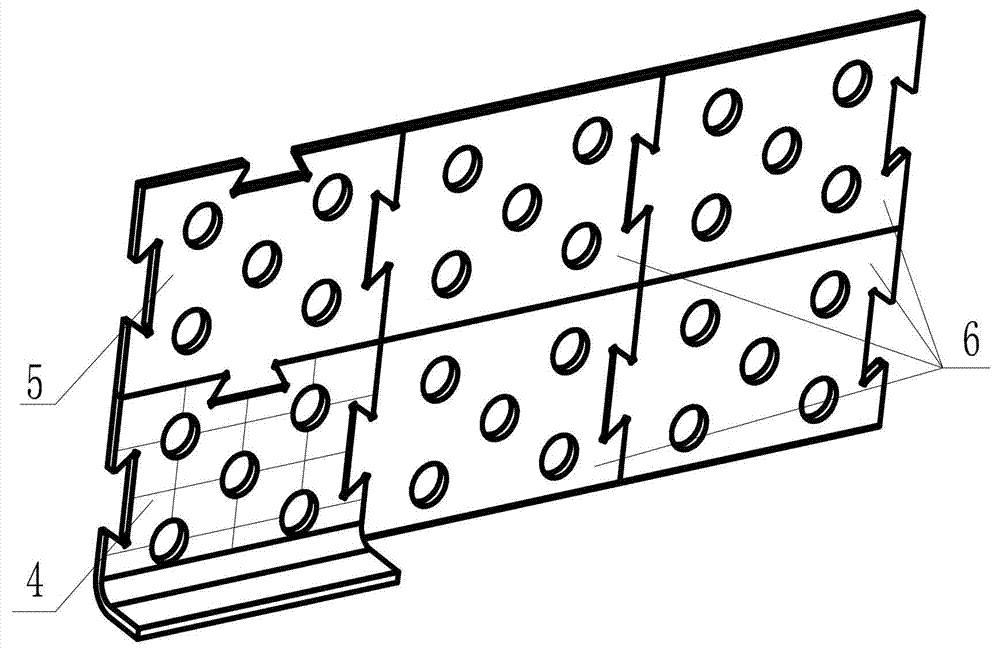

The invention provides a quick positioned detecting method for a thickness size of a variable thickness part and an auxiliary detecting device. Firstly, a plate-shaped auxiliary detecting device provided with a right-angle bending edge is produced, and array holes regularly arranged by a plurality of different detecting points and hole center longitude and latitude scribed lines are formed on the plate surface of the auxiliary detecting device; and then, the hole system positions on the plate surface of the auxiliary detecting device are leant against and bonded on a plane to be detected of the variable thickness part, a positioning reference hole (9) is determined in end holes of the hole system, and a Y-direction size scribed line (7) and an X-direction size scribed line (8) are scribed on the part to be detected respectively; the Y-direction size scribed line and the X-direction size scribed line are aligned to the hole center longitude and latitude scribed lines of the hole system when detecting; and finally, different positions of the hole system are touched by a probe of an ultrasonic thickness meter to obtain thickness values which are obtained by measuring. The auxiliary detecting device comprises an L-shaped mother board which is provided with a right-angle bending edge, and combination son boards extending to two sides; and the whole surface of the device is provided with a regular hole system, and dovetail grooves and dovetail bosses for positioning and connection.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

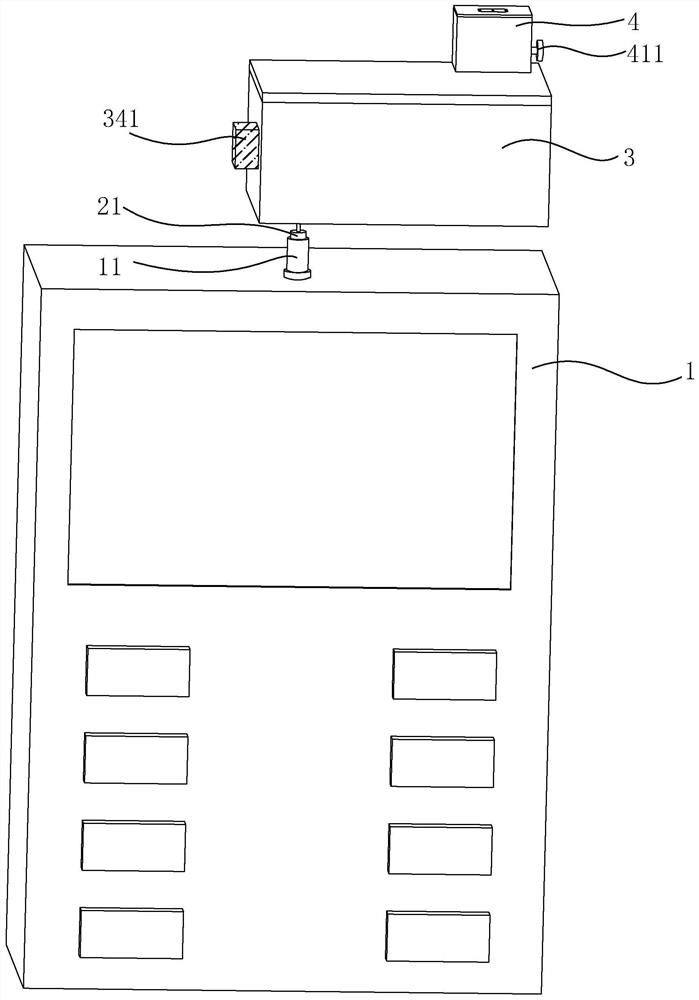

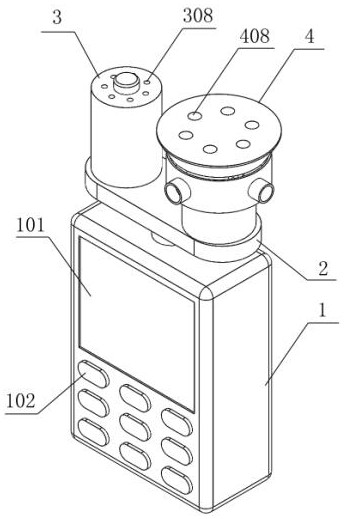

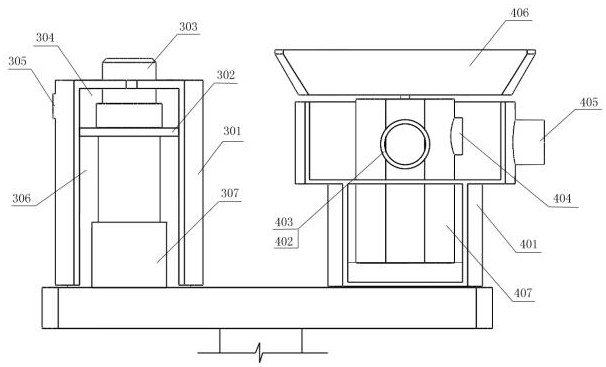

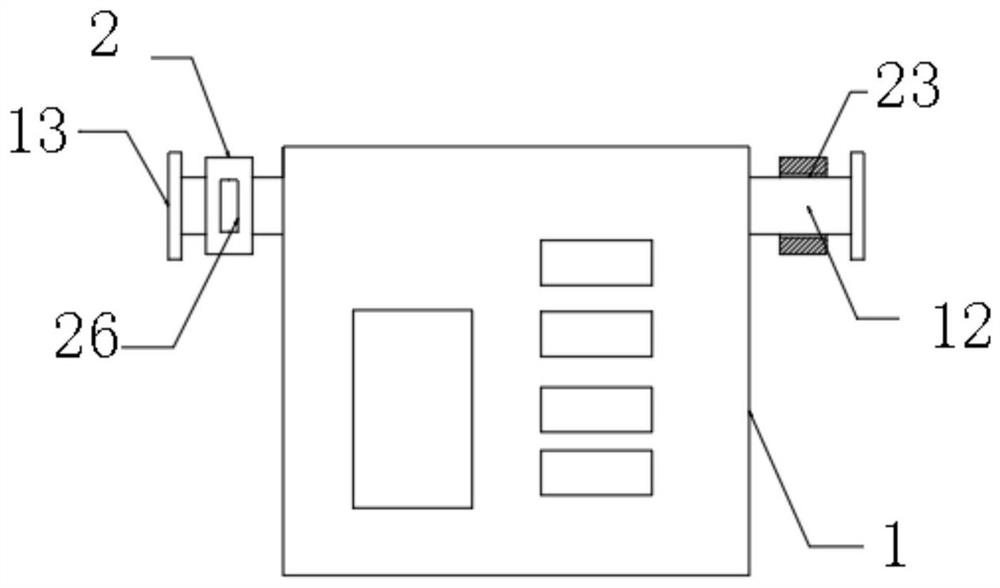

Integrated ultrasonic thickness gauge for taking coupling agent in pressing mode

PendingCN113251964ASupplement at any timeEasy accessUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterEngineering

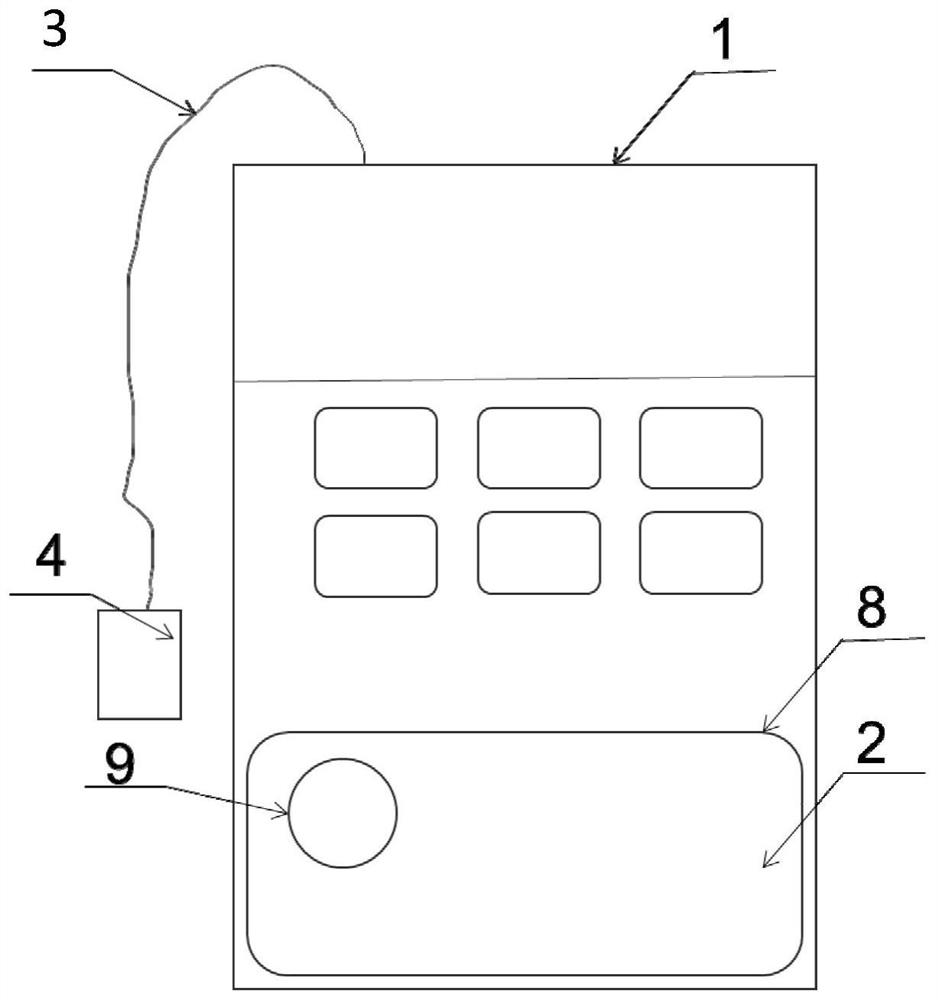

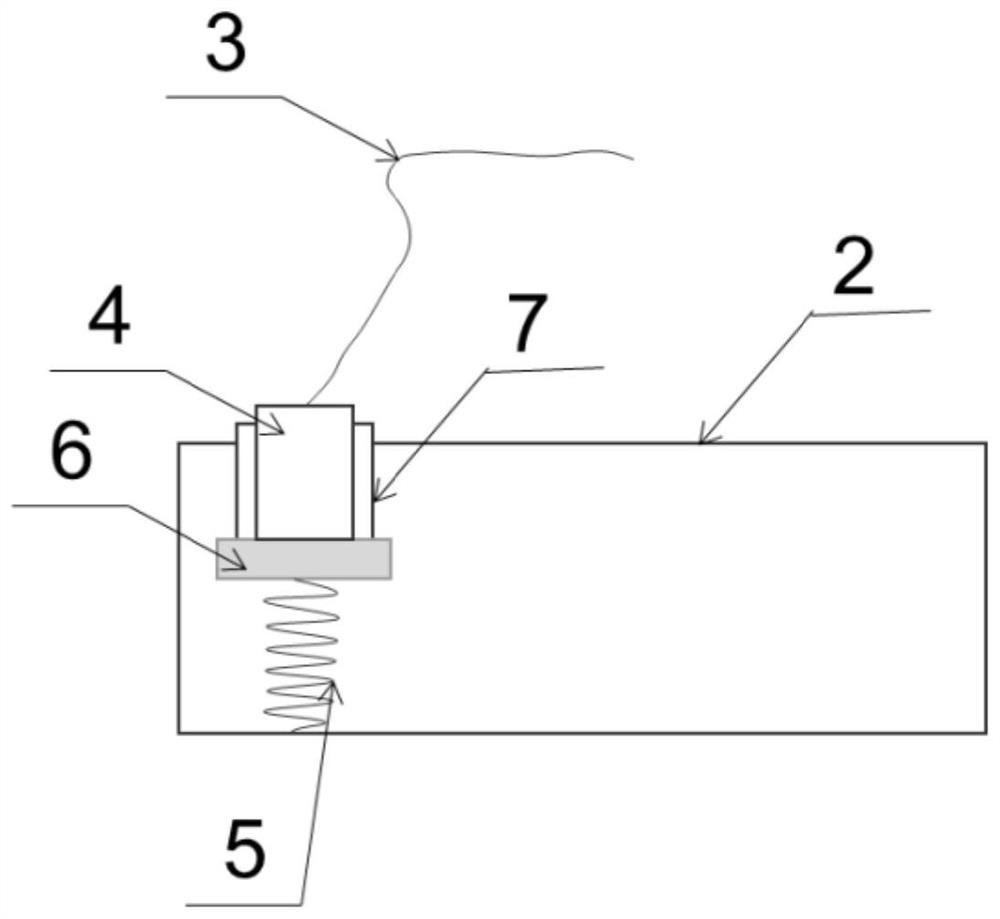

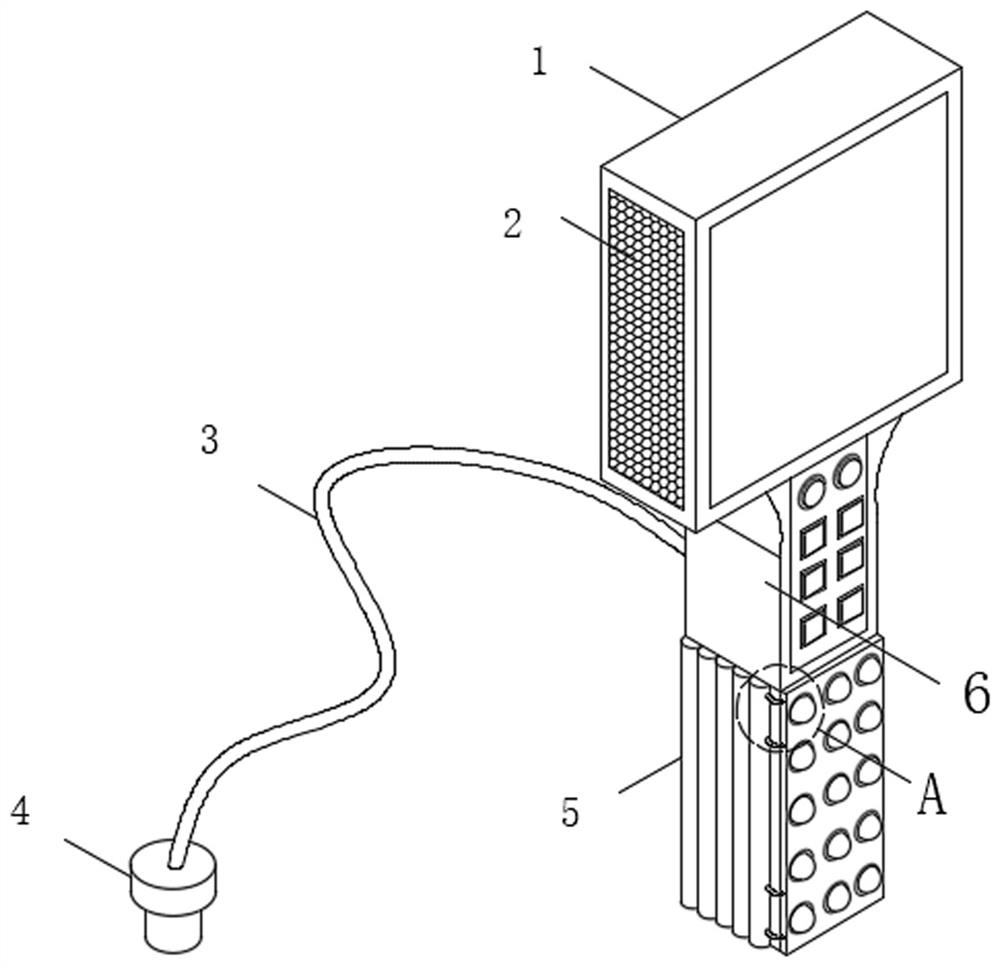

The invention discloses an integrated ultrasonic thickness gauge for taking a coupling agent in a pressing manner. The integrated ultrasonic thickness gauge is characterized by comprising an ultrasonic thickness gauge body, an ultrasonic probe and an embedded liquid storage box for storing the coupling agent, wherein the embedded liquid storage box is embedded in the ultrasonic thickness gauge body; an elastic pressing mechanism is arranged on the embedded liquid storage box; the elastic pressing mechanism is communicated with a liquid storage cavity of the embedded liquid storage box, and the ultrasonic probe achieves taking and using of the coupling agent in the embedded liquid storage box by pressing the elastic pressing mechanism. Herein, the coupling agent storage device and the thickness gauge are integrated, so that the coupling agent can be conveniently taken and used in the measuring process, the coupling agent in the coupling agent storage box can be supplemented at any time, and the use is convenient; meanwhile, the coupling agent is taken in a pressing mode, so that the coupling agent is evenly smeared and waste is avoided, and calibration and thickness measurement are convenient. The device is simple and unique in structure, easy to produce and operate, convenient to use, good in effect and good in economic benefit, and the working accuracy is greatly improved.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

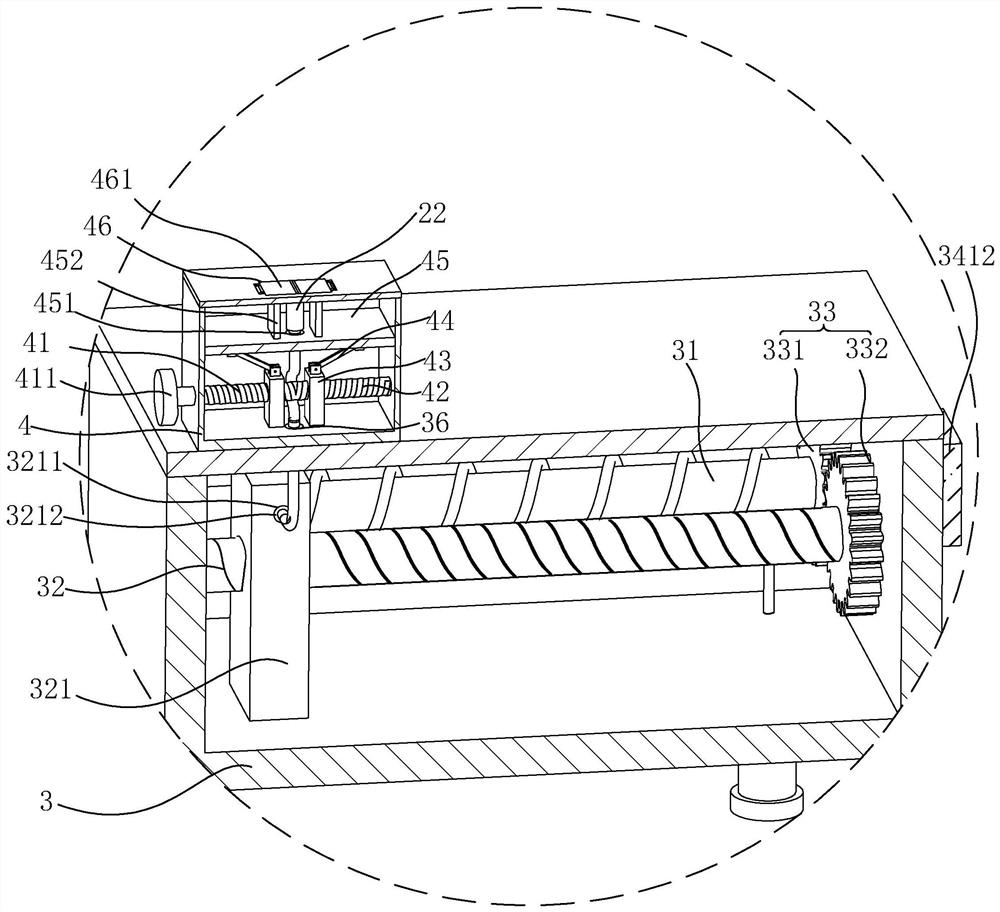

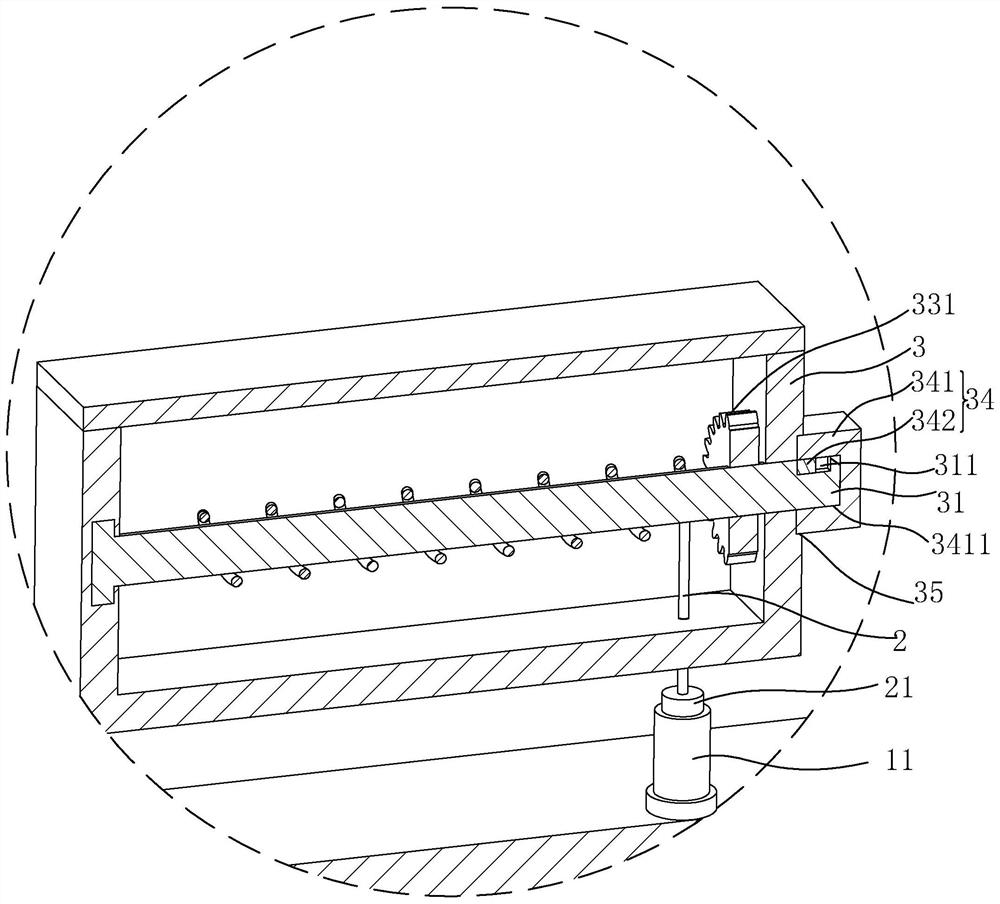

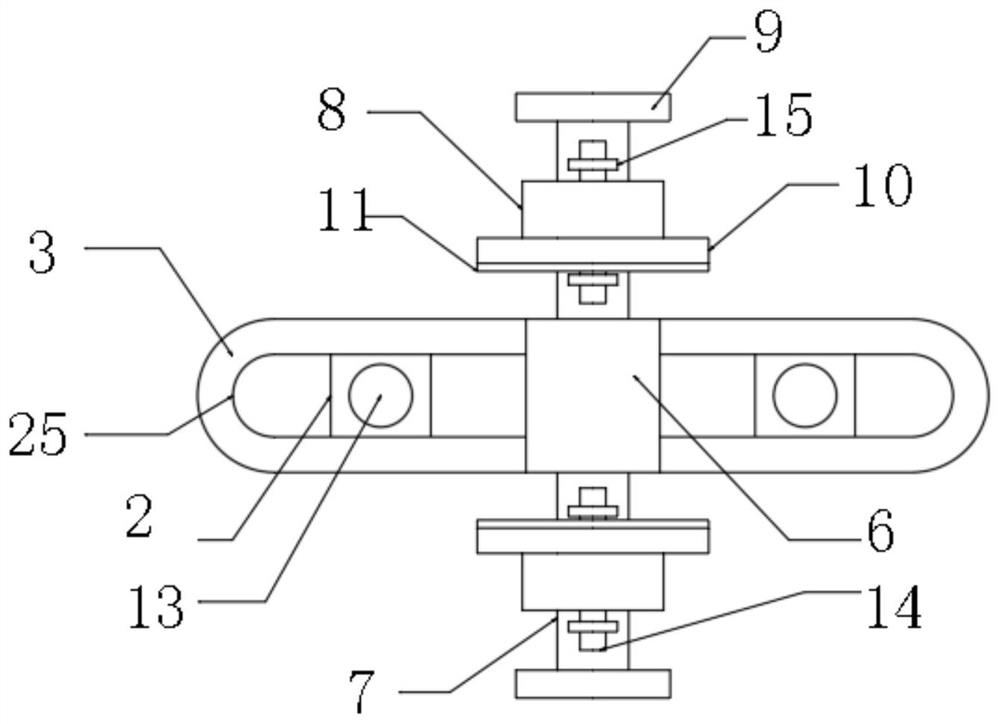

Ultrasonic thickness gauge with coupling agent recovery function

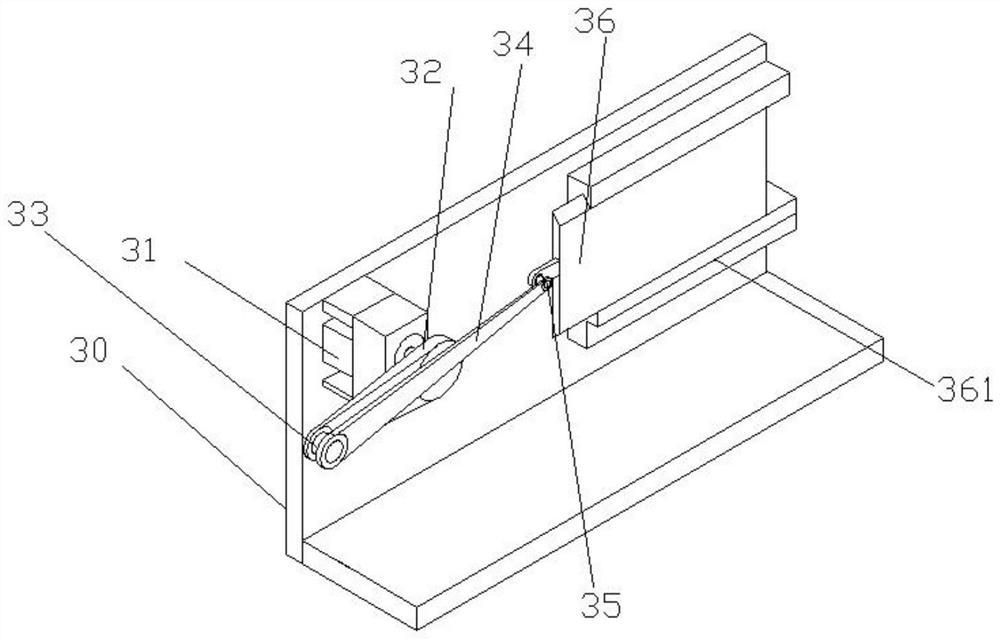

ActiveCN113776472AAvoid duplication of workImprove work efficiencyUsing subsonic/sonic/ultrasonic vibration meansConveyor partsPachymetersUltrasonic pachymeter

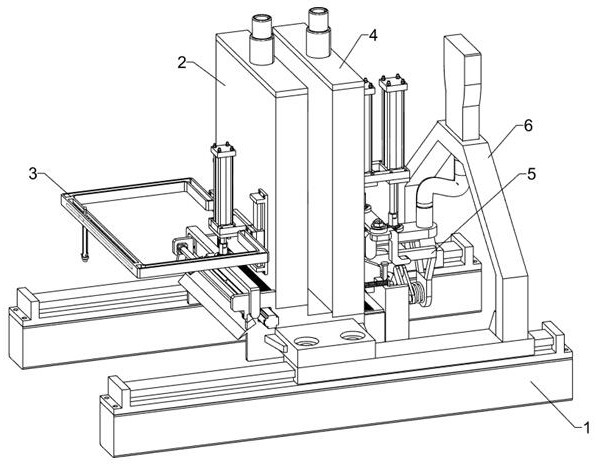

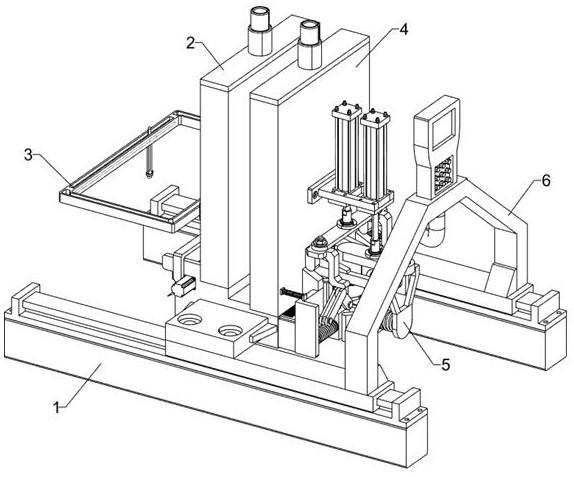

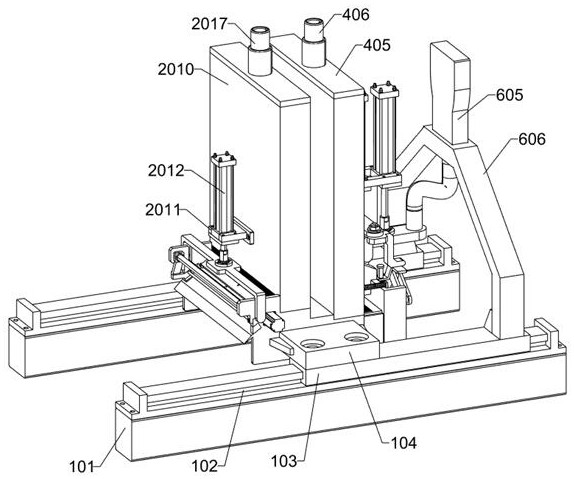

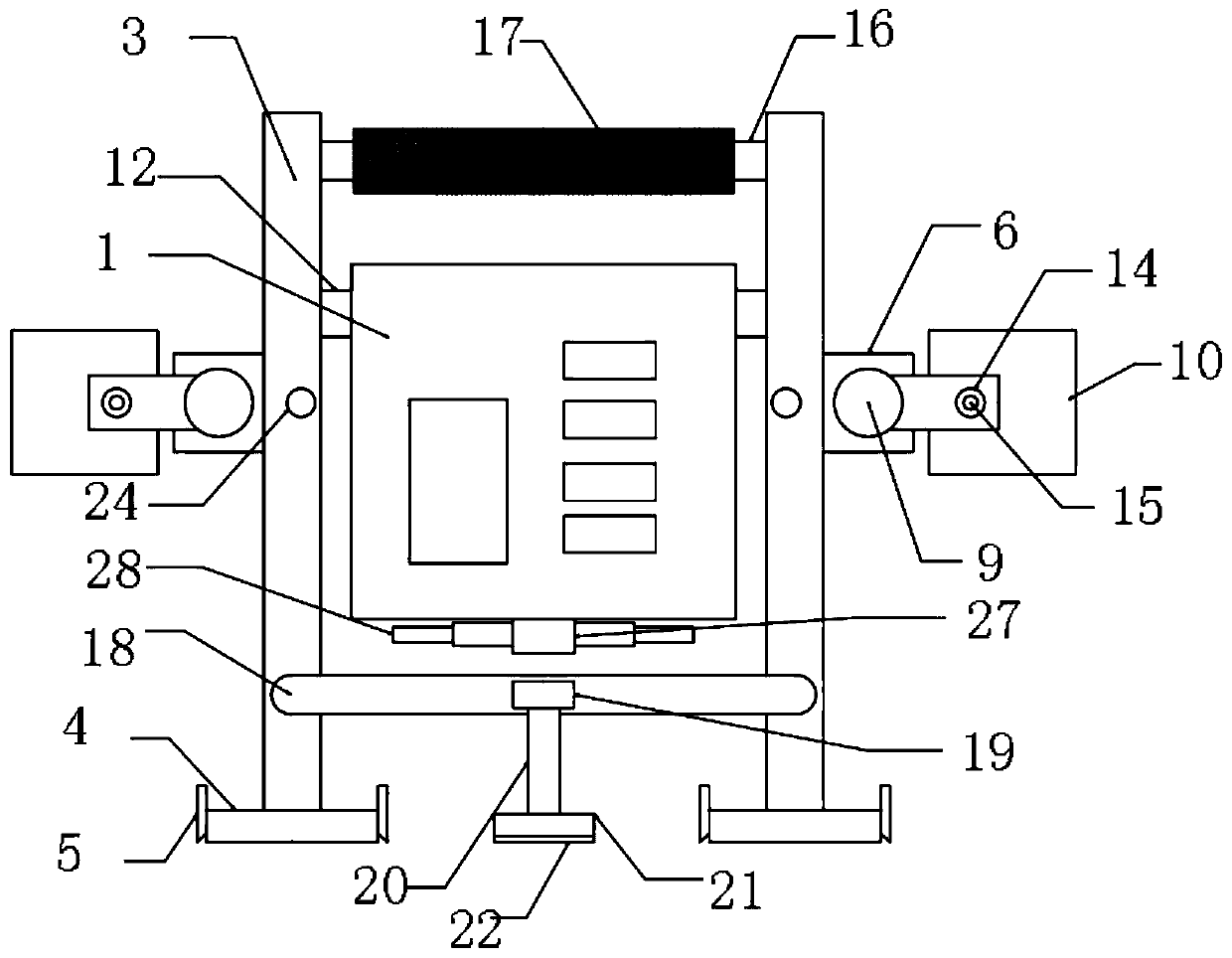

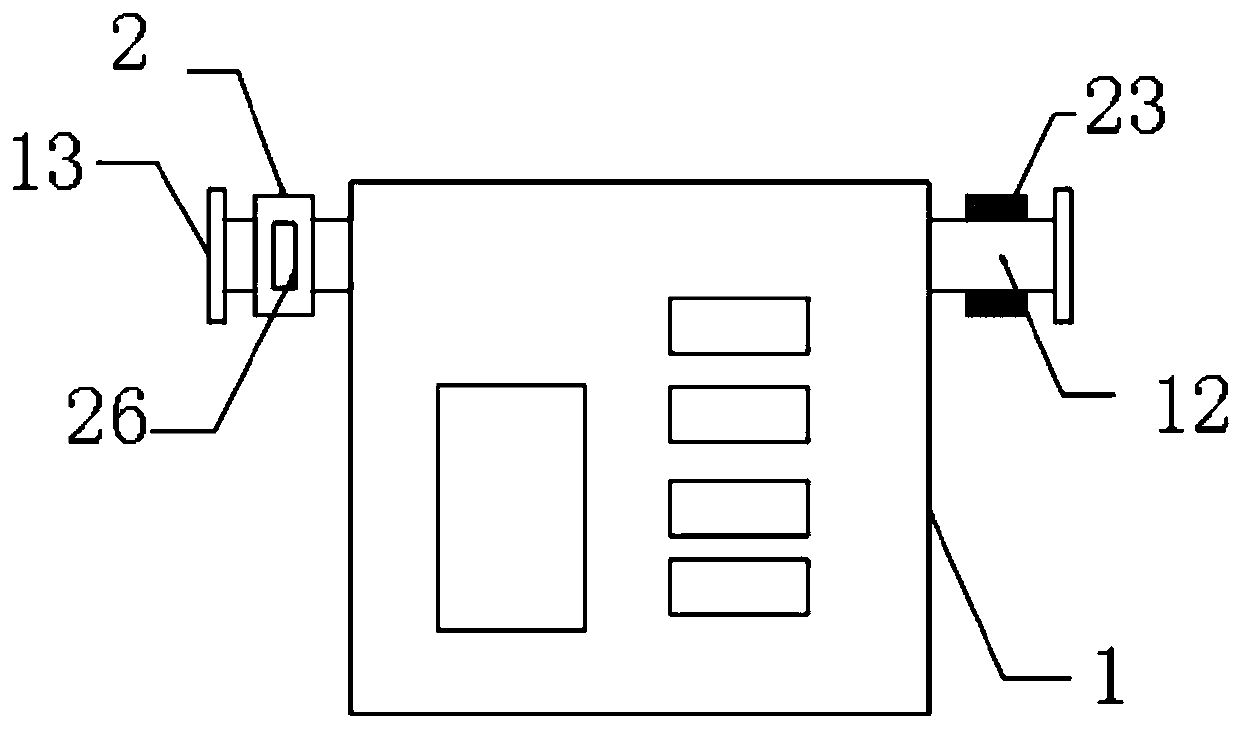

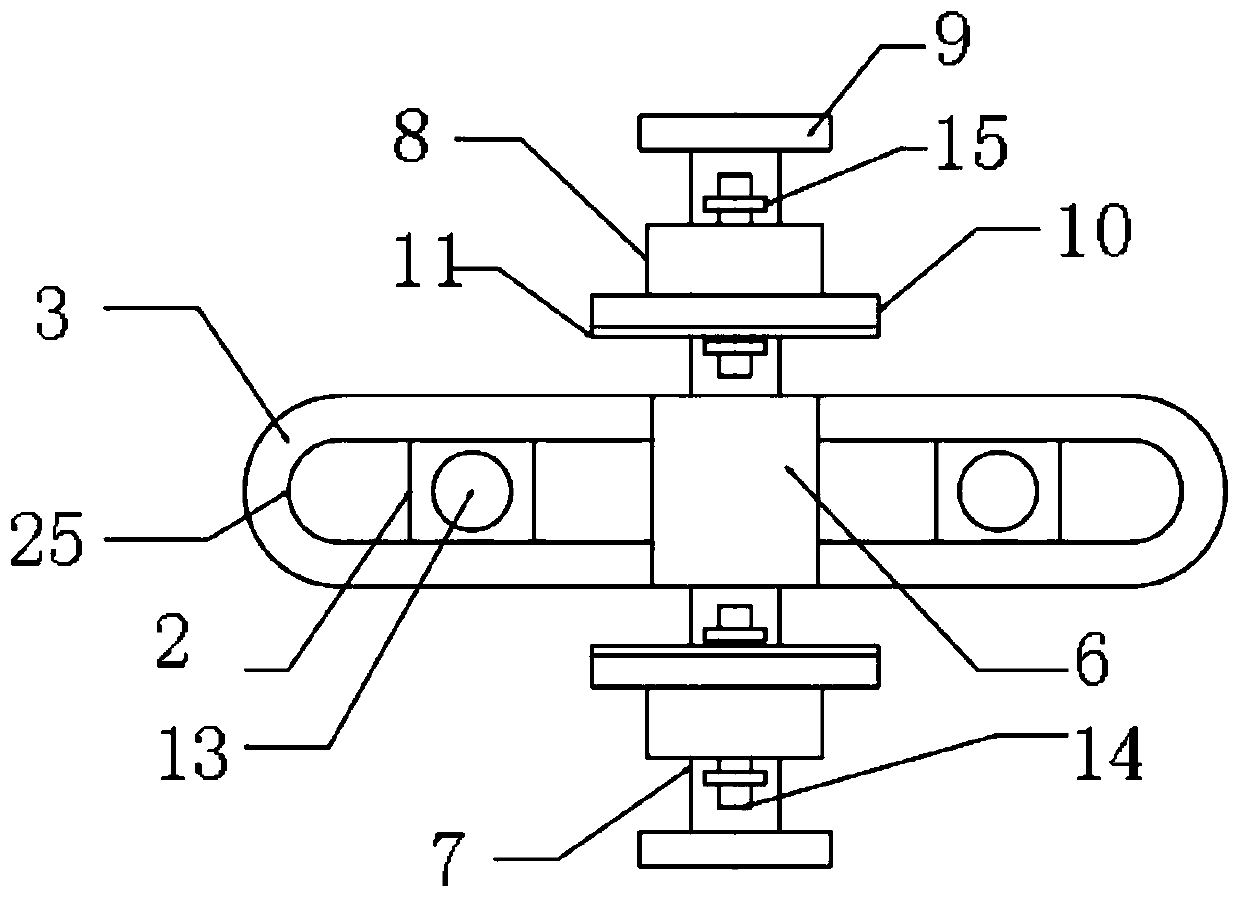

The invention relates to the technical field of test instruments, in particular to an ultrasonic thickness gauge with a coupling agent recovery function. The problems that an existing ultrasonic thickness gauge cannot recycle all coupling agents at a time, the coupling agents in different states cannot be recycled in a classified mode, and the recycled coupling agents in the different states are mixed with one another are solved. According to the technical scheme, the ultrasonic thickness gauge with the coupling agent recovery function comprises a propelling supporting system, a pollution layer recovery system and the like, and the pollution layer recovery system is installed on the propelling supporting system. According to the coupling agent recycling device, all coupling agents are recycled at a time, repeated work is avoided, the work efficiency is improved, the coupling agents in different states are recycled synchronously in a classified mode, the coupling agents in different states are prevented from being mixed, the quality of the recycled coupling agents is improved, and the treatment work difficulty is reduced.

Owner:胜利油田东强机电设备制造有限公司

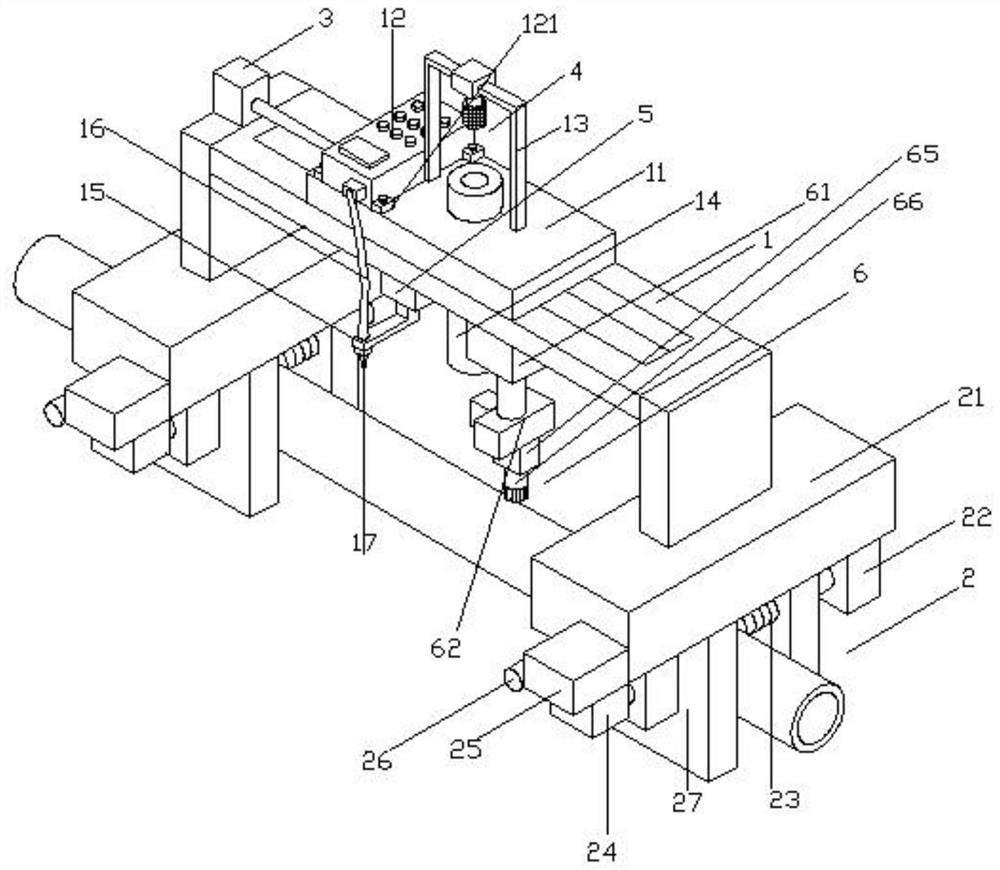

Ultrasonic thickness gauge with automatic coupling agent extrusion device

The invention provides an ultrasonic thickness gauge with an automatic coupling agent extrusion device, which comprises a support, clamping mechanisms are fixedly connected below two ends of the support, an objective table is slidably connected above the support, a pushing mechanism is fixedly connected on one side of the objective table, and the ultrasonic thickness gauge is detachably connected on the objective table. One side of the ultrasonic thickness gauge is fixedly connected with a supporting rod, the supporting rod is fixedly connected with an extrusion mechanism, the extrusion mechanism is slidably connected to a storage barrel, the storage barrel is fixedly connected to an objective table, a lifting mechanism is fixedly connected to the lower portion of the objective table, and one side of the storage barrel and the lower portion of the objective table are fixedly connected with a first electric push rod. The driving end of the first electric push rod is fixedly connected with the cleaning mechanism. The support and a to-be-detected pipeline are fixed together through the clamping mechanism, and the cleaning mechanism, the extruding mechanism and the lifting mechanism are driven by the pushing mechanism to sequentially clean rust, smear a coupling agent and detect the pipeline.

Owner:广西建通工程质量检测有限公司

Thickness detection equipment for wooden door production

ActiveCN110672048ASimple structureSimple and fast operationUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterElectric machinery

Owner:衡东振好木制品有限公司

Ultrasonic thickness gauge and detection method thereof

ActiveCN112985315ARealize pay-offStable storageUsing subsonic/sonic/ultrasonic vibration meansPilot holeUltrasonic pachymeter

The invention relates to an ultrasonic thickness gauge, and relates to the technical field of thickness measuring equipment. The thickness gauge comprises a thickness gauge body and a storage box, a storage rod and a guide screw rod are rotatably connected in the storage box, a connecting wire is wound outside the storage rod, one end of the connecting wire is provided with a plug, the top of the thickness gauge is provided with a socket for adaptive plugging of the plug, and the other end of the connecting wire is provided with a probe; a driving assembly used for driving the storage rod to rotate and fixing the rotating position is arranged at one end of the storage rod, a linkage assembly used for driving the storage rod and the guide screw rod to rotate synchronously is arranged between the storage rod and the guide screw rod, and the guide screw rod is sleeved with a guide block in a threaded mode. A guide hole for a connecting wire to pass through is formed in the guide block in a penetrating manner; and the gauge has the effect of realizing stable storage of the connecting line and the probe.

Owner:浙江城际特种设备检测有限公司

Non-intrusive corrosion on-line detection equipment for fluorine chemical device

PendingCN113390372ASimple structureRealize online detection functionAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterDisplay device

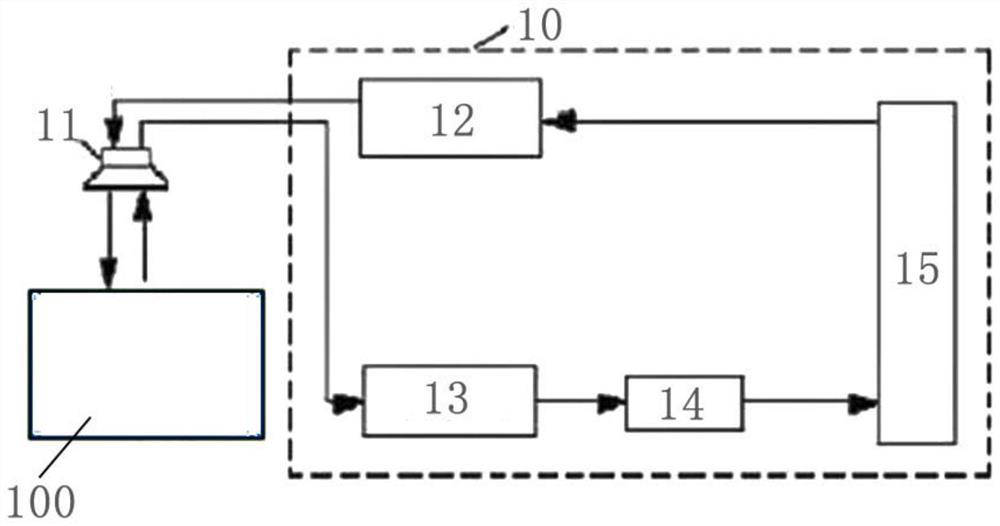

The invention provides non-intrusive corrosion online detection equipment for a fluorine chemical engineering device. The equipment comprises an ultrasonic detection module, a temperature compensation module, an ultrasonic data analysis module, an ultrasonic thickness gauge, a detection equipment host and a display, and is characterized in that the detection equipment host is connected with the ultrasonic thickness gauge and the ultrasonic data analysis module respectively; the ultrasonic data analysis module is connected with the ultrasonic detection module and the temperature compensation module, the ultrasonic detection module comprises an ultrasonic transmitter, an ultrasonic receiver and corresponding waveguide rods, and the temperature compensation module is fixed on the waveguide rods. According to the ultrasonic high-temperature thickness measuring method based on the waveguide technology, the waveguide rod structure is optimized, non-intrusive corrosion online detection applied to the high-risk environment of a fluorine chemical engineering device can be achieved, the online detection function under the normal-temperature and high-temperature working conditions is achieved, the precision is higher, and meanwhile long-period monitoring can be achieved for key parts.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

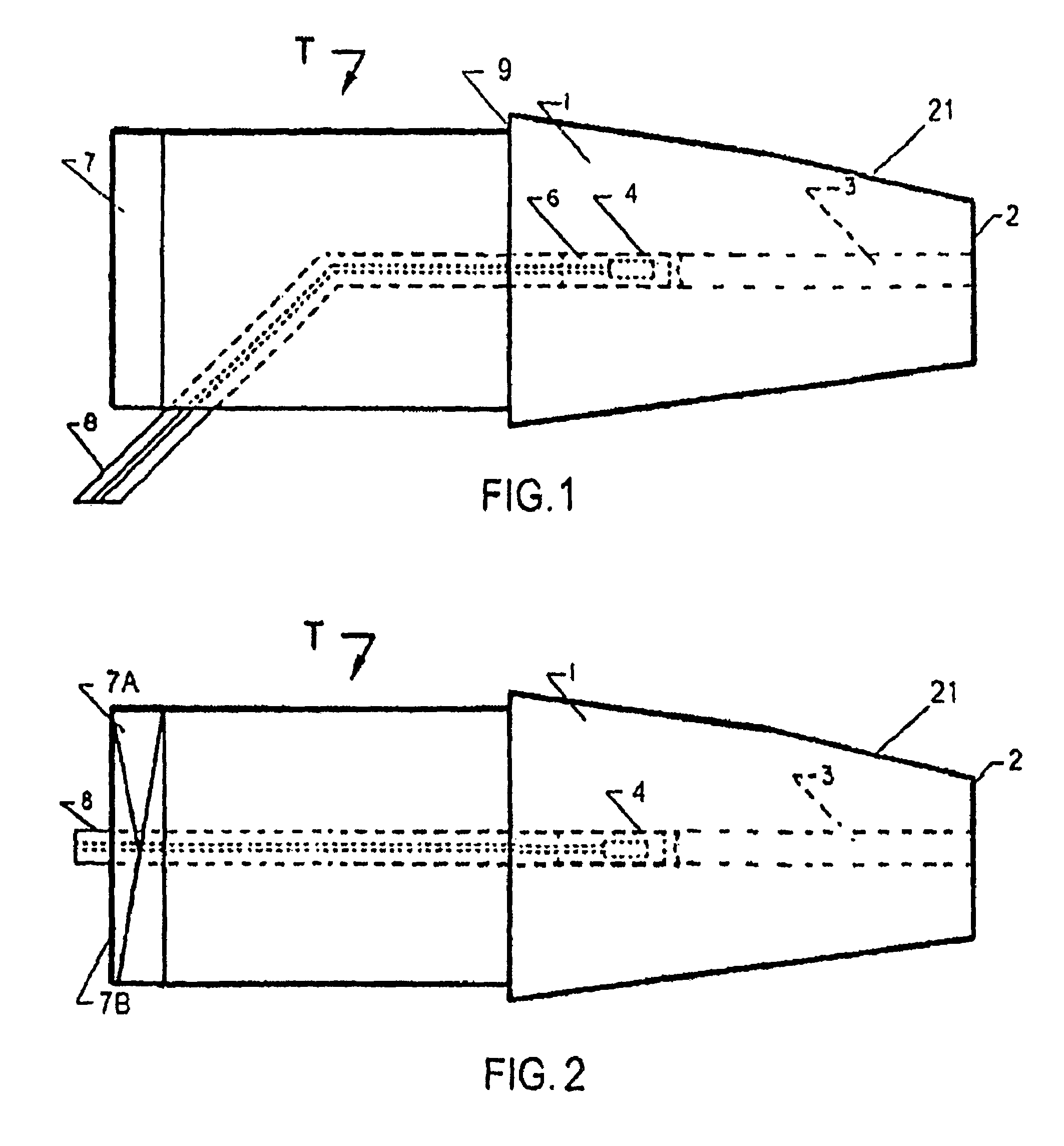

Combined applanation tonometer and ultrasonic pachymeter

InactiveUS7452330B2Convenient, quick and accurate determinationAccurately reflectTonometersCorneal surfaceApplanation tonometer

An improved apparatus and method of intraocular pressure determination is disclosed in which applanation tonometry is done with an ultrasonic transducer. The method allows for increased accuracy of intraocular pressure determination based upon adjustment of applanation tonometry for subjacent corneal thickness. The device allows for the operator to view the corneal surface and the pattern of dye to determine the precise endpoint of applanation.

Owner:SUBLASE

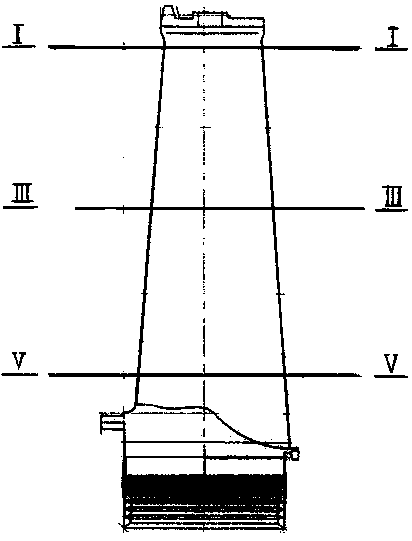

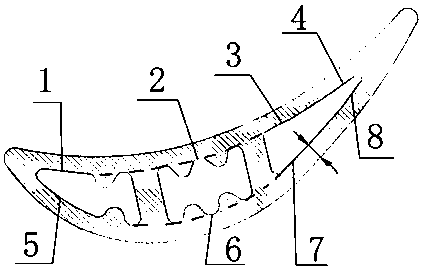

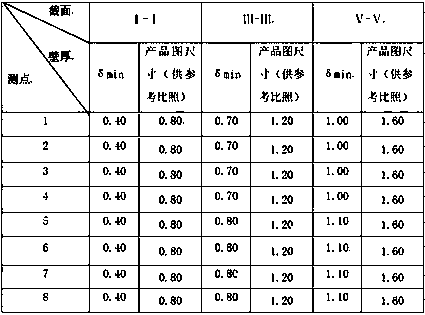

Method for detecting wall thickness of turbojet engine high-pressure turbine blade through ultrasonic waves

InactiveCN110926384AReliable dataUsing subsonic/sonic/ultrasonic vibration meansTurbine bladeUltrasonic pachymeter

The invention discloses a method for detecting the wall thickness of a turbojet engine high-pressure turbine blade through ultrasonic waves. The method comprises the following steps of S1, selecting an ultrasonic thickness gauge with waveform display; S2, manufacturing a blade back surface template and a blade basin surface template; S3, manufacturing a standard part for measurement and comparison; cutting a scrapped turbojet engine high-pressure turbine blade into four standard thickness test blocks with different thicknesses along the longitudinal direction of the scrapped turbojet engine high-pressure turbine blade; grinding the standard thickness test blocks, detecting the thickness value after grinding, ensuring that the specifications of the four standard thickness test blocks are 0.4 mm, 0.8 mm, 1.2 mm and 1.6 mm respectively, and ensuring that the material trademarks of the standard thickness test blocks are the same as the material of the high-pressure turbine blade of the turbojet engine to be detected; and S4, measuring the thickness of the blade. The method has the beneficial effects that the process steps are simple, the thickness measurement precision is high, the data is real and reliable, and the flight safety is ensured.

Owner:PLA NO 5719 FACTORY

Ultrasonic thickness gauge for ductile iron pipe

PendingCN114877836AGuaranteed smooth progressEnsure accuracy andUsing subsonic/sonic/ultrasonic vibration meansProcess efficiency improvementUltrasonic pachymeterGraphite

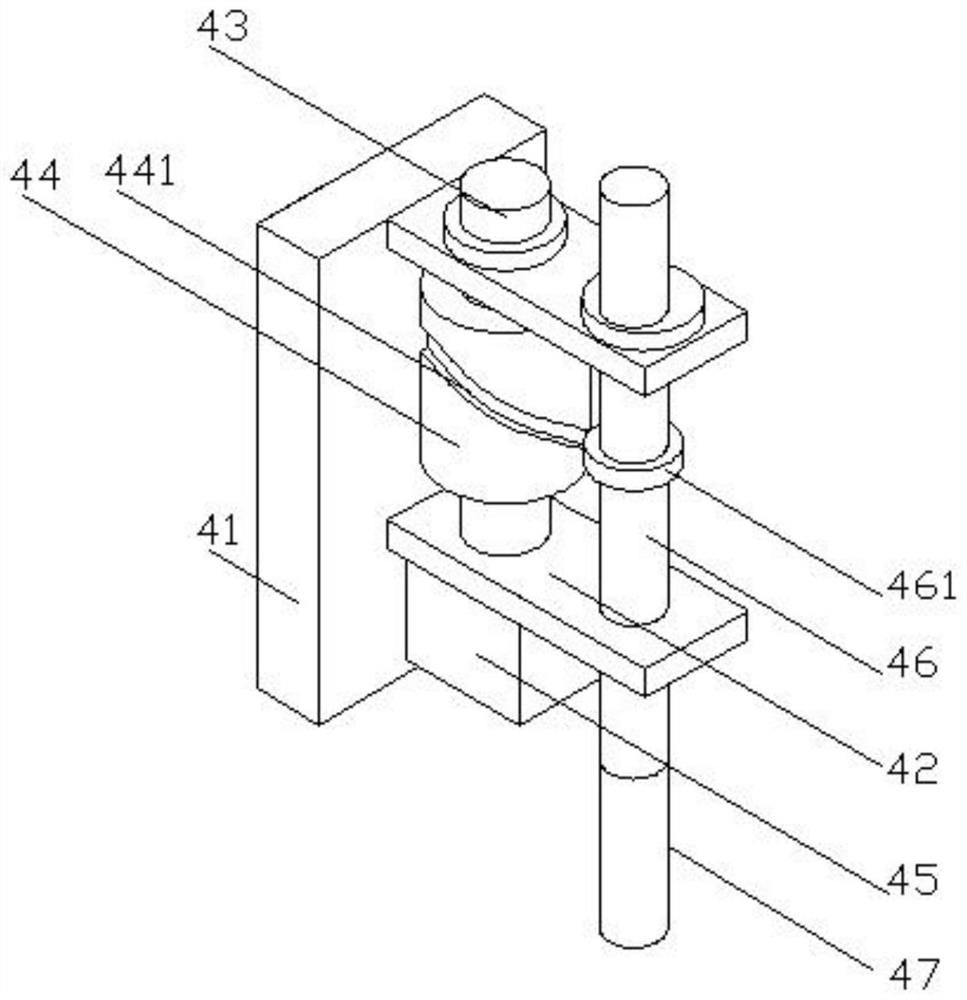

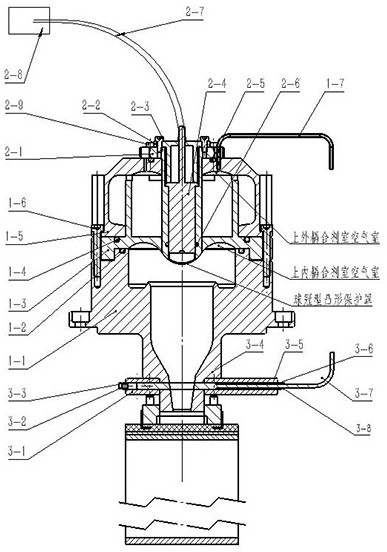

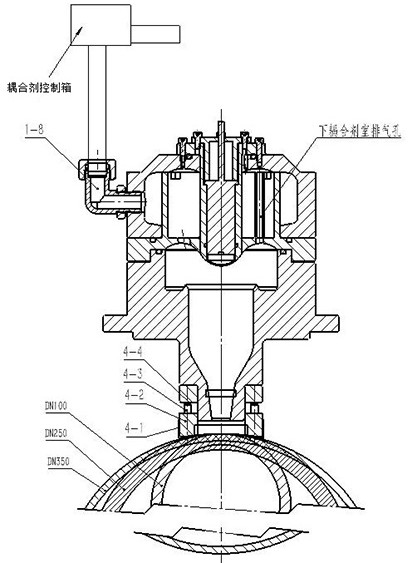

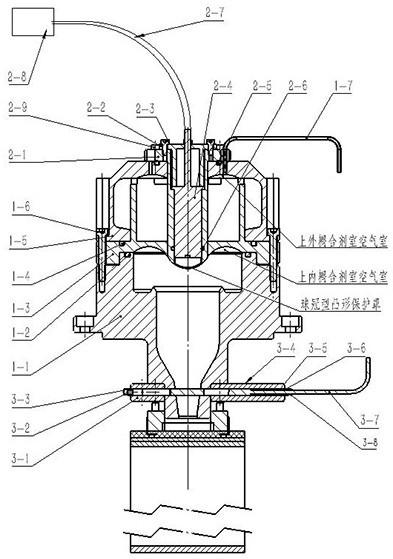

The invention discloses an ultrasonic thickness gauge for a ductile iron pipe, and relates to the technical field of pipeline detection. The ultrasonic thickness gauge comprises a coupling agent chamber, an ultrasonic probe mechanism, a coupling agent opening and closing mechanism, a self-adaptive attaching mechanism and a coupling agent control box, the coupling agent opening and closing mechanism is installed on the lower side of the coupling agent chamber through a screw, and the self-adaptive attaching mechanism is installed on the coupling agent opening and closing mechanism through a guide bolt. The ultrasonic probe mechanism is arranged on the coupling agent chamber, and the coupling agent control box is connected with the coupling agent chamber through a coupling agent pipeline. The ultrasonic thickness gauge for the spheroidal graphite cast pipe can change the ultrasonic probe according to different pipeline materials, realizes the measurement of the wall thickness of pipelines made of different materials, and has the characteristics of compact structure, rapidness and convenience in detection, easiness in maintenance and low use cost.

Owner:NANJING INST OF TECH

Ultrasonic thickness gauge and management communication system

PendingCN114509031AEfficient dischargeAvoid stickingHybrid switching systemsData switching by path configurationCommunications systemUltrasonic pachymeter

The invention discloses an ultrasonic thickness gauge and a management communication system, and belongs to the technical field of ultrasonic thickness gauges.The ultrasonic thickness gauge comprises a display body and a handle, the display body is fixedly installed at the top of the handle, a built-in motor is transversely and fixedly installed in the display body, and a driving bevel gear is fixedly installed at one end of an output shaft of the built-in motor; a reciprocating lead screw is longitudinally and rotationally installed in the display body, a driven bevel gear is fixedly installed at one end of the outer portion of the reciprocating lead screw, and the driving bevel gear and the driven bevel gear are connected in a meshed mode; compared with a fixed heat dissipation structure, the heat dissipation device has the advantages that the movable heat dissipation assembly is arranged in the heat dissipation device, the heat dissipation effect is more excellent, outer meshing gears of side mounting rods can be meshed with inner racks while heat dissipation is conducted, side cleaning discs can synchronously move and rotate, a heat dissipation net on the side face can be completely cleaned, and the heat dissipation effect is better. Dust raised in the heat dissipation process can be effectively prevented from being attached to the heat dissipation net, and the heat dissipation effect of equipment is continuously guaranteed.

Owner:河南迅捷检测中心技术服务有限公司

An Ultrasonic Thickness Measuring Equipment with High Measuring Accuracy

ActiveCN108592833BHigh measurement accuracyImprove operational efficiencyGrinding drivesUsing subsonic/sonic/ultrasonic vibration meansUltrasonic thickness measurementUltrasonic pachymeter

Owner:东营市乾润石油工程技术服务有限责任公司

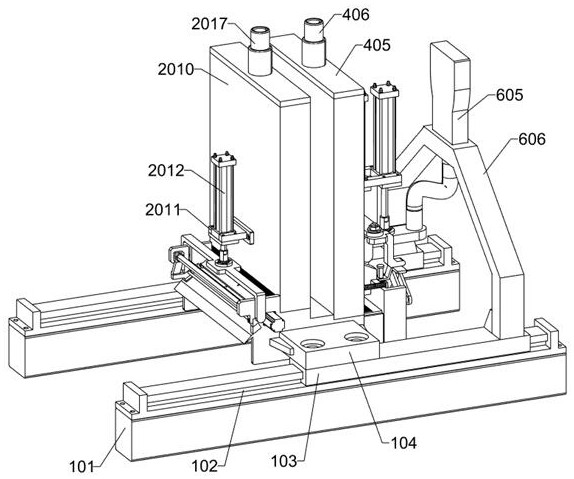

Multifunctional integrated ultrasonic detection equipment

InactiveCN113686276AQuick sandingRapid positioningUsing subsonic/sonic/ultrasonic vibration meansUltrasonic thickness measurementUltrasonic pachymeter

The invention discloses multifunctional integrated ultrasonic detection equipment, which comprises an ultrasonic thickness gauge host, an ultrasonic probe device and a pneumatic polishing device, wherein a bracket is arranged at the top part of the ultrasonic thickness gauge host, the ultrasonic probe device is arranged at one end of the bracket, and couplant spraying and ultrasonic thickness measurement can be carried out at the same time by means of the ultrasonic probe device; and the pneumatic grinding device is arranged at the other end of the bracket, and grinding and dust collection can be conducted at the same time through using the pneumatic grinding device. The multifunctional integrated ultrasonic detection equipment has the beneficial effects that the ultrasonic thickness gauge product integrating a grinding machine, a coupling agent tank and a thickness gauge can realize rapid positioning, grinding, coupling agent spraying and continuous measurement, and is convenient to operate; and the equipment is miniaturized, integrated and convenient to carry.

Owner:ZHEJIANG UNIV OF TECH

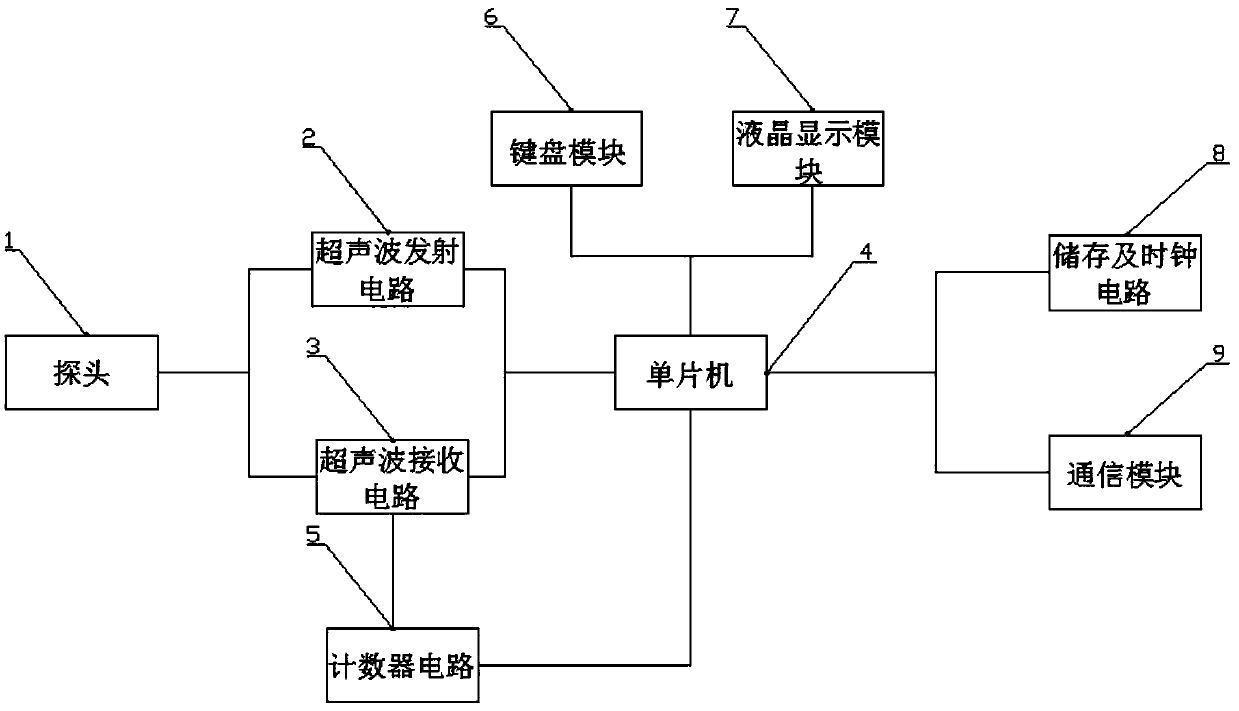

Portable ultrasonic thickness meter

InactiveCN110715625AReduce volumeEasy to operateUsing subsonic/sonic/ultrasonic vibration meansLiquid-crystal displayUltrasonic pachymeter

The invention provides a portable ultrasonic thickness meter, and belongs to the technical field of sensor detection. The portable ultrasonic thickness meter mainly comprises a probe, an ultrasonic transmitting circuit, an ultrasonic receiving circuit, a single-chip microcomputer, a counter circuit, a keyboard module, a liquid crystal display module, a storage and clock circuit, and a communication module and is characterized in that the probe is connected to the ultrasonic transmitting circuit, the ultrasonic receiving circuit is connected to the probe, the ultrasonic transmitting circuit andthe ultrasonic receiving circuit are both connected to the single-chip microcomputer, the single-chip microcomputer is connected to the counter circuit, and the counter circuit is connected to the ultrasonic receiving circuit. The portable ultrasonic thickness meter has the advantages of small size, convenient operation and the like, can realize the accurate measurement, also has a programmable function, can store a great deal of information, and can meet the requirements of routing inspection in factories.

Owner:NORTHWEST A & F UNIV

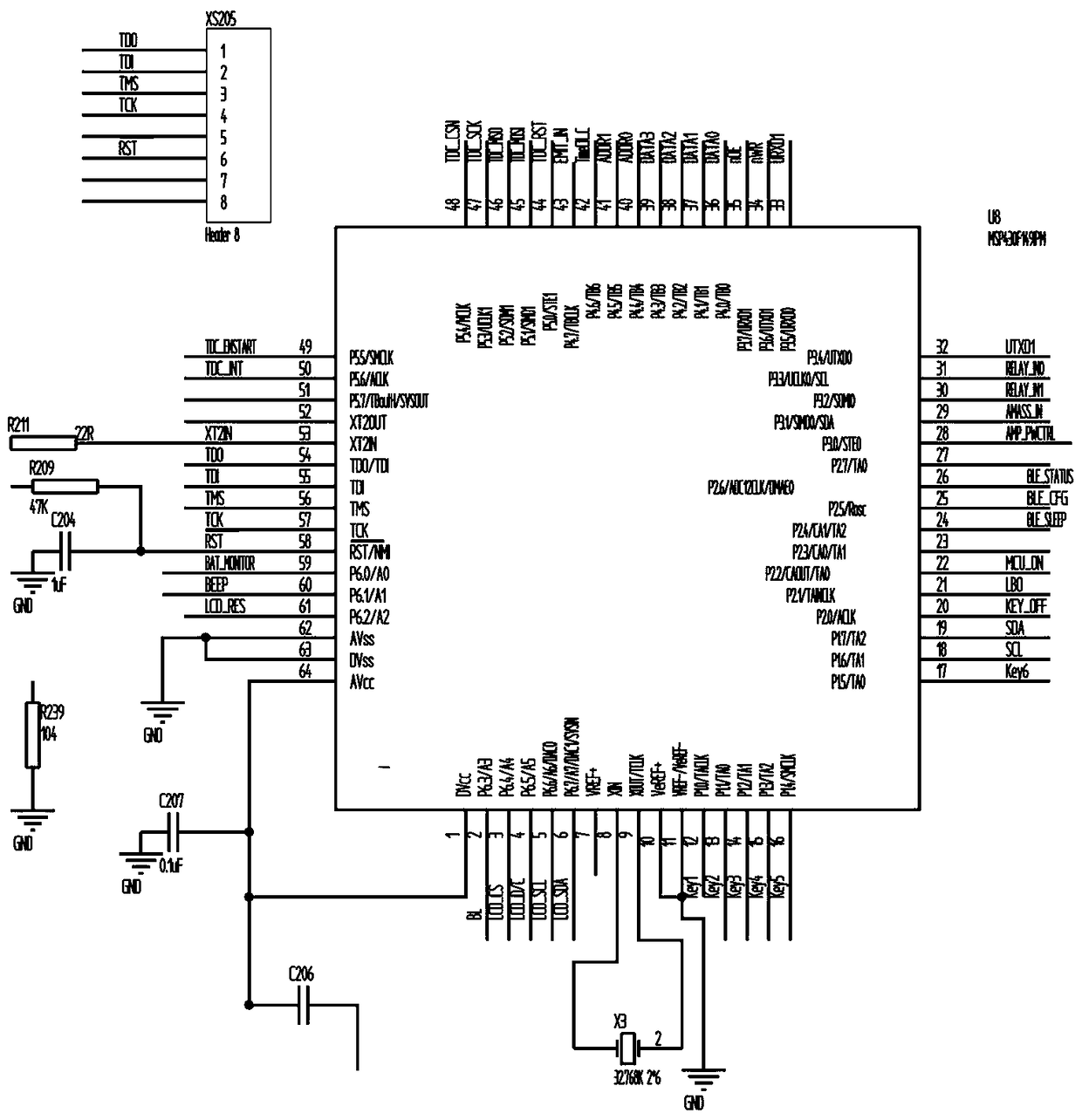

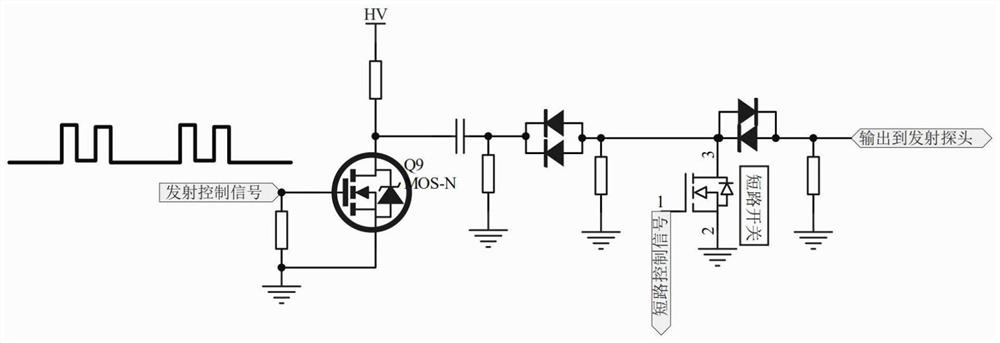

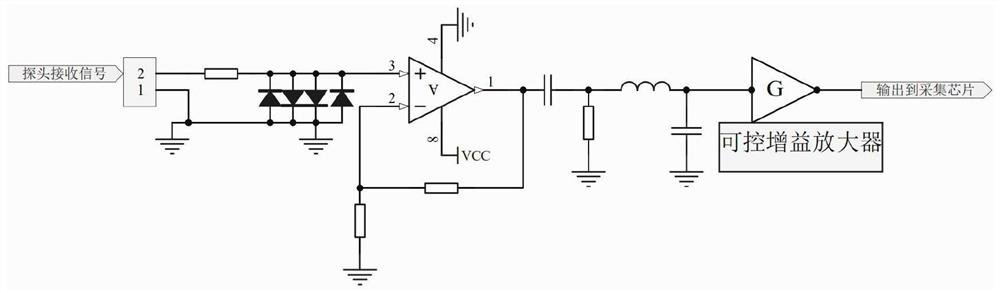

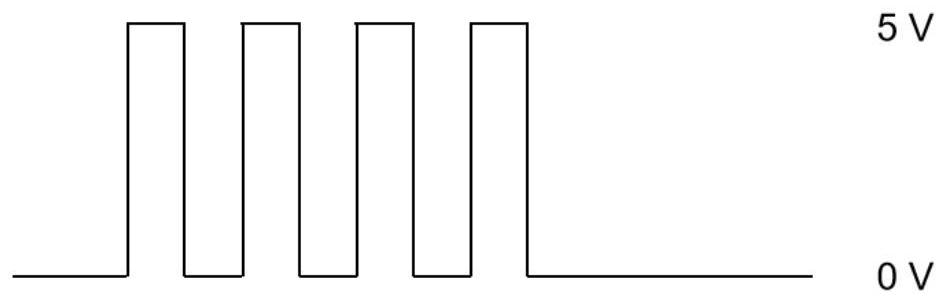

High-precision ultrasonic thickness gauge based on multi-echo principle

InactiveCN108759735ASolve the disadvantages that thickness measurement cannot measure thin partsLow measurement limitUsing subsonic/sonic/ultrasonic vibration meansMicrocontrollerProgrammable logic device

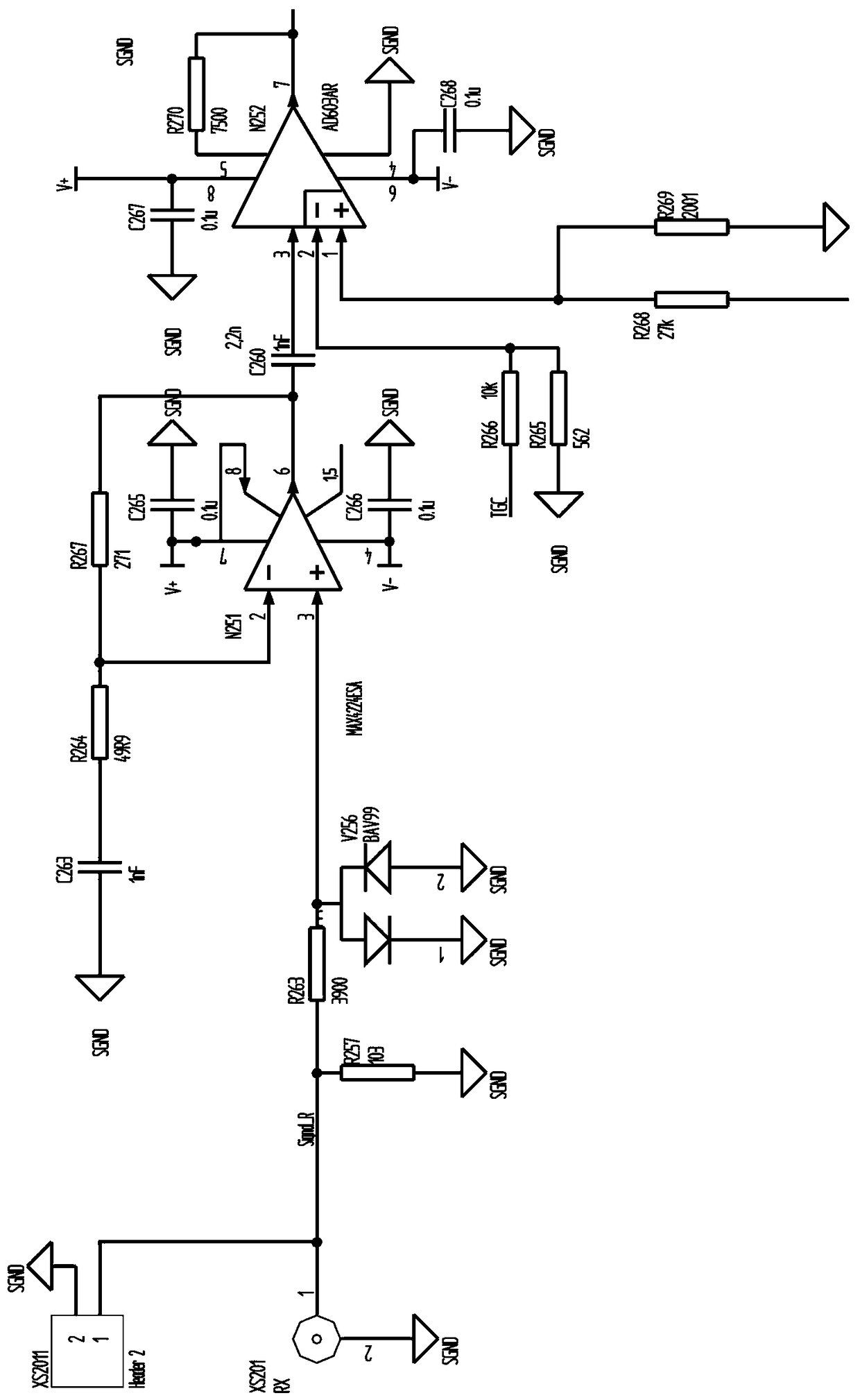

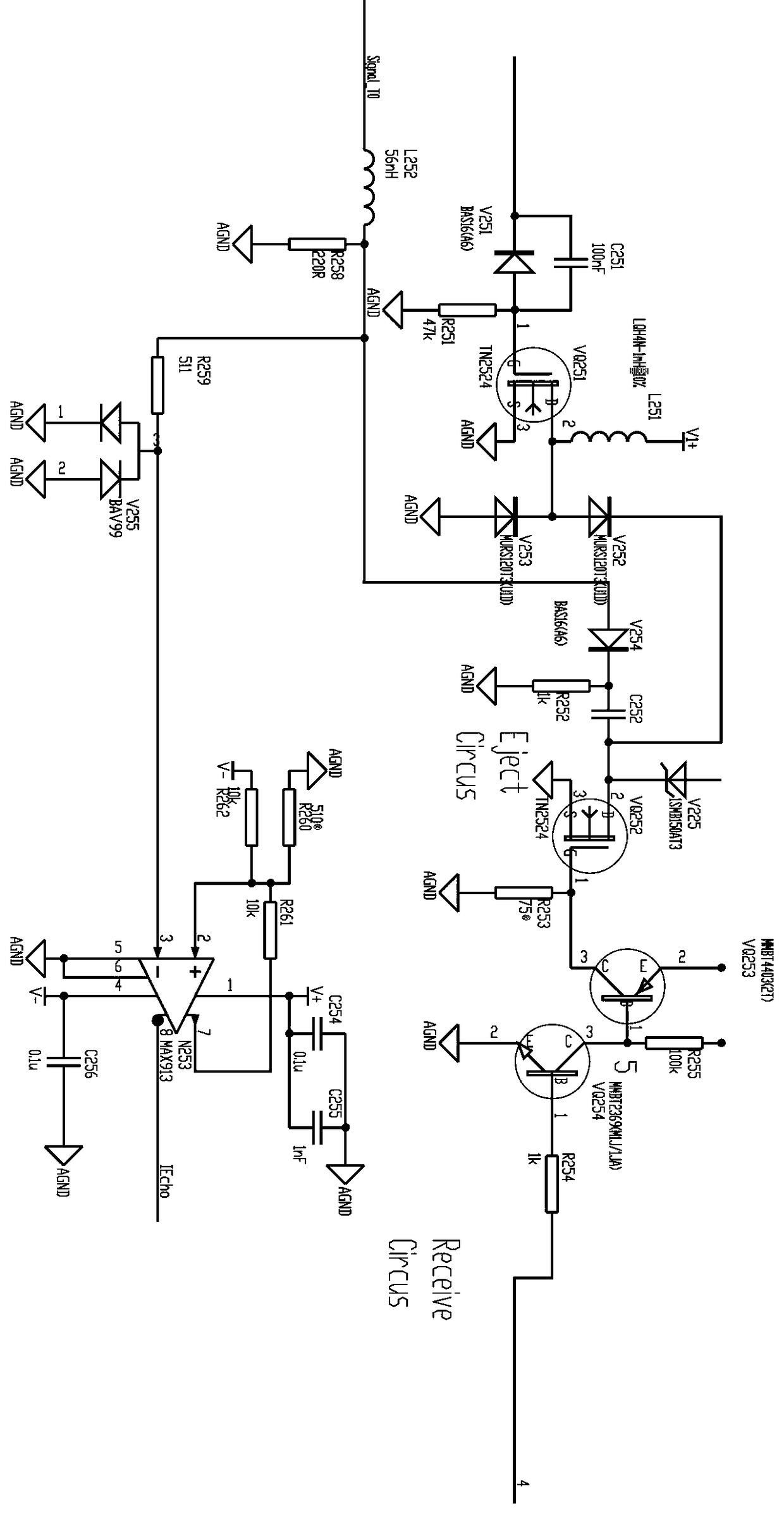

The invention discloses a high-precision ultrasonic thickness gauge based on a multi-echo principle, which comprises a main control module, an ultrasonic voltage receiving and amplifying module, a high-voltage pulse transmitting module and a programmable logic module, wherein the main control module comprises a single chip microcomputer U8; the ultrasonic voltage receiving and amplifying module comprises a variable gain amplifier N252; the high-voltage pulse transmitting module comprises an operational amplifier N253; and the programmable logic module comprises a programmable logic device. Thehigh-precision ultrasonic thickness gauge based on the multi-echo principle has the following advantages that a thin part can be measured; the lower limit range of a measurement range can be expandedto 0.15mm; coating removal measurement can be realized, and influences of rust, electroplating and other treatments on thickness measurement can be avoided.

Owner:山东中科普锐检测技术有限公司

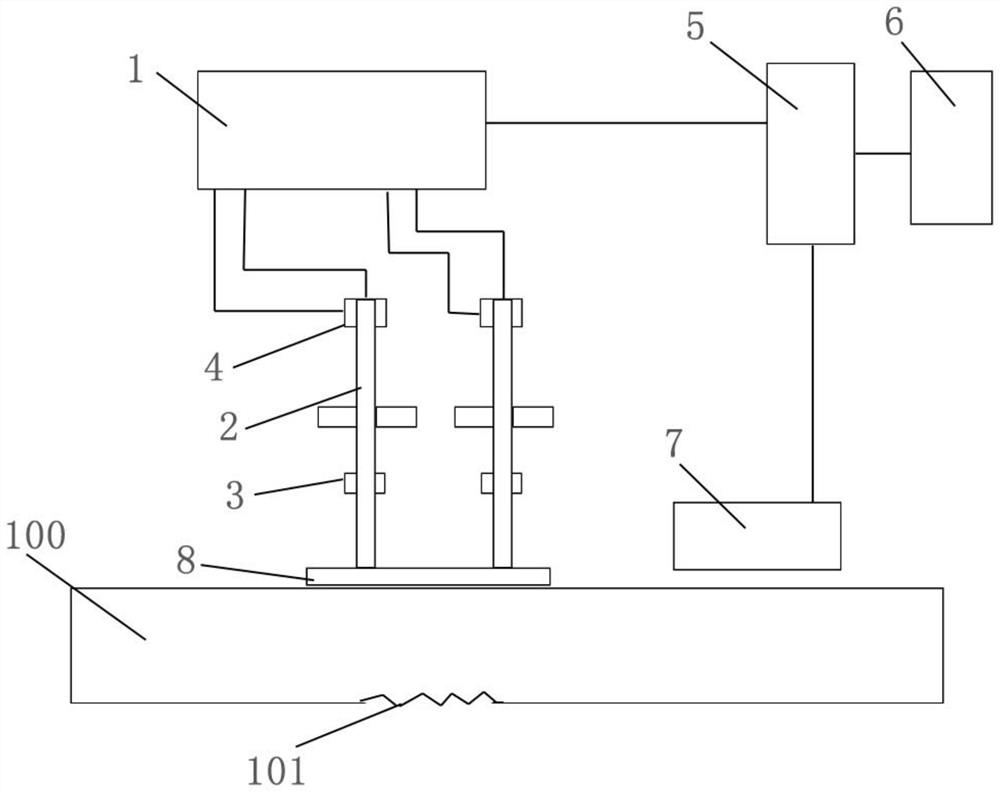

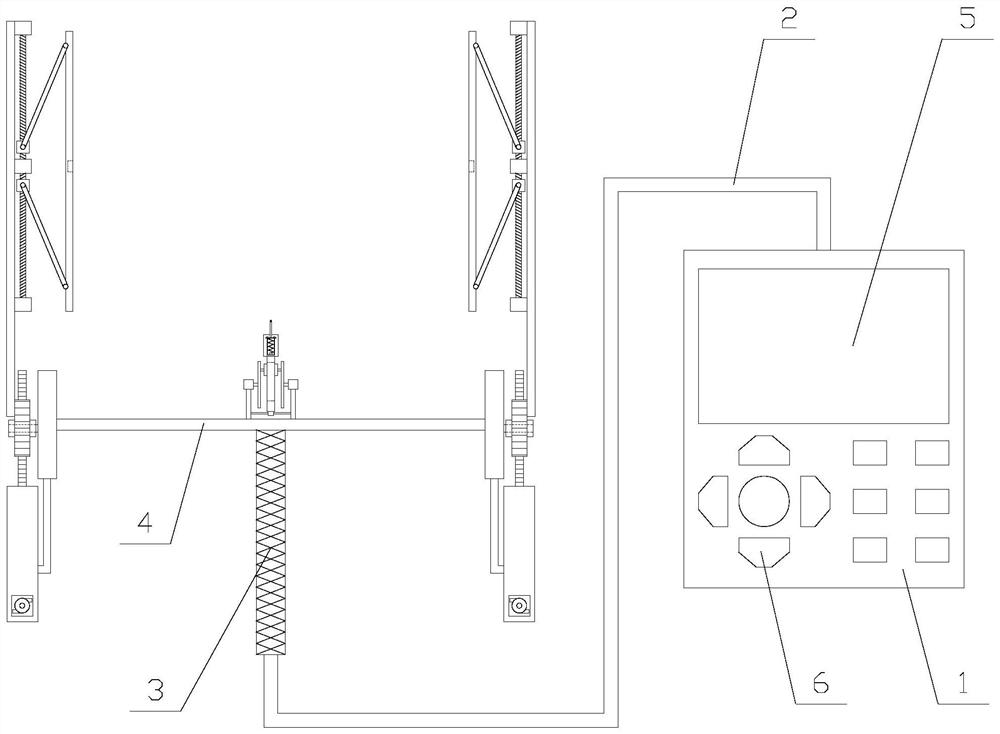

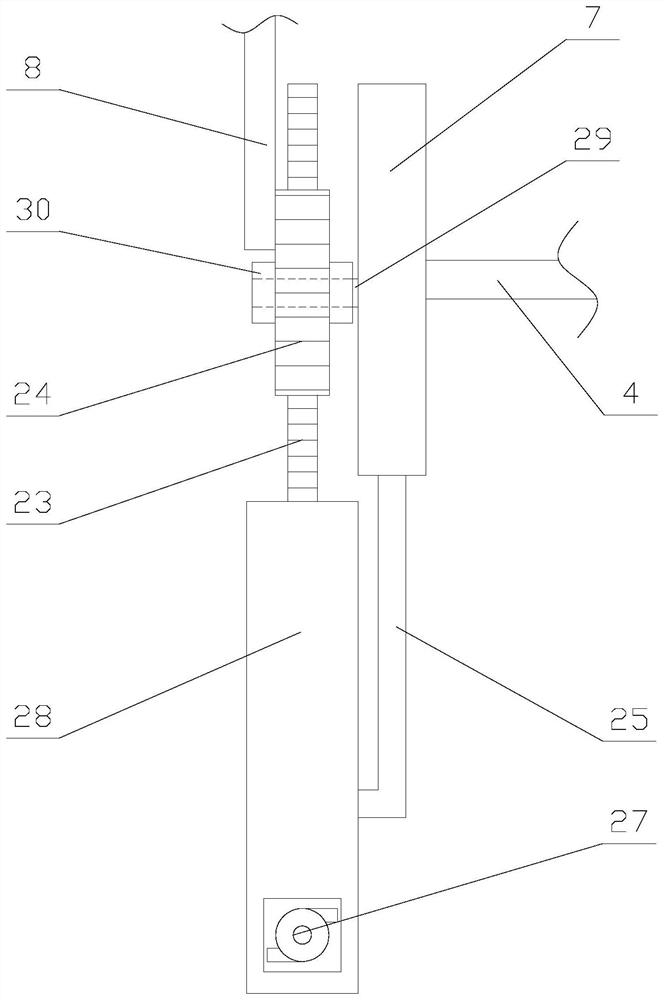

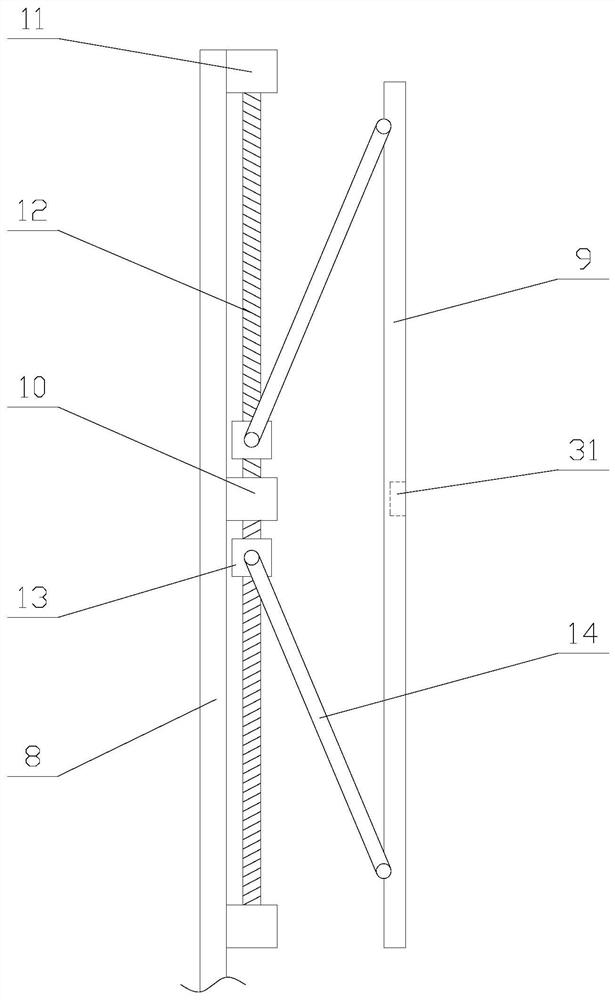

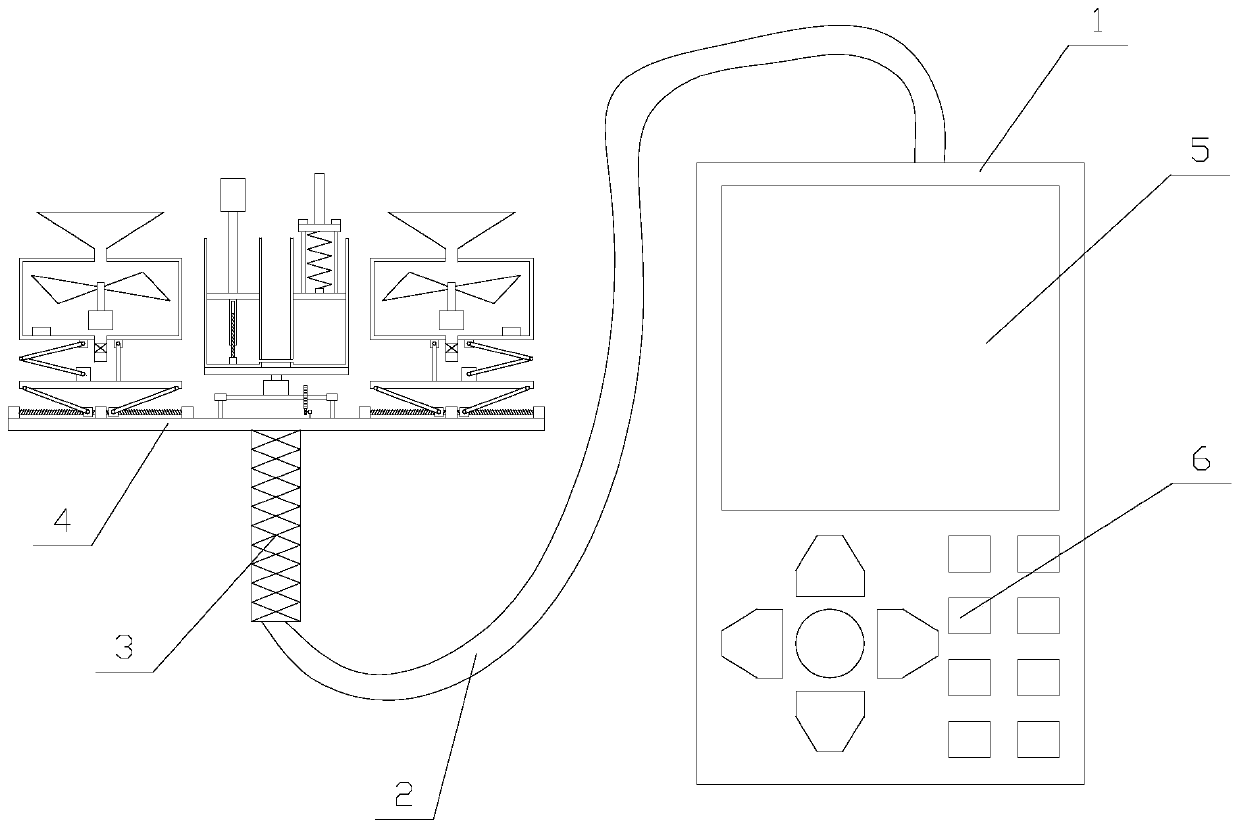

An Ultrasonic Thickness Gauge Easy to Fix and Adjust

ActiveCN108844504BFlexible structureAvoid jitterUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterMeasuring instrument

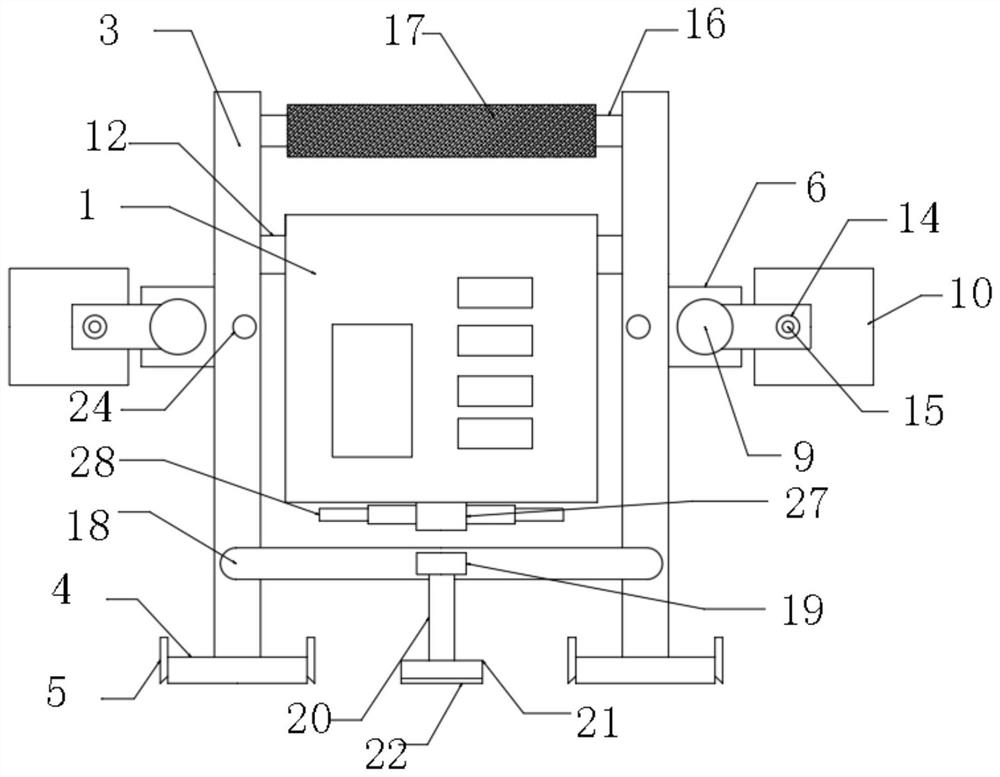

The invention relates to a convenient-fixing and adjustment ultrasonic thickness measuring instrument which comprises a host computer, a connecting line, a holding rod, a push plate, a detecting mechanism and two fixing mechanisms. The host computer is provided with a display screen and a plurality of buttons. The fixing mechanism comprises a connecting board, a receiving assembly, a side plate, afixing assembly and a movable plate. The fixing assembly comprises a first motor and two fixing units. The fixing unit comprises a bearing, a first driving shaft, a movable block and a supporting rod. The detecting mechanism comprises a driving rod, a swinging rod, a probe, a detecting assembly, a collar, a fixing rod and two driving assemblies. The driving assembly comprises a connecting rod, asecond motor and a turntable. According to the convenient fixing and adjustment ultrasonic thickness measuring instrument, a to-be-detected pipe is clamped by two movable boards through the fixing mechanism, thereby preventing probe shake in a detecting process. Furthermore, the probe angle is adjusted through the detecting mechanism so that the probe is aligned with the axis of the pipe for measurement, thereby improving detecting precision of the equipment.

Owner:东营钧辰石油设备有限责任公司

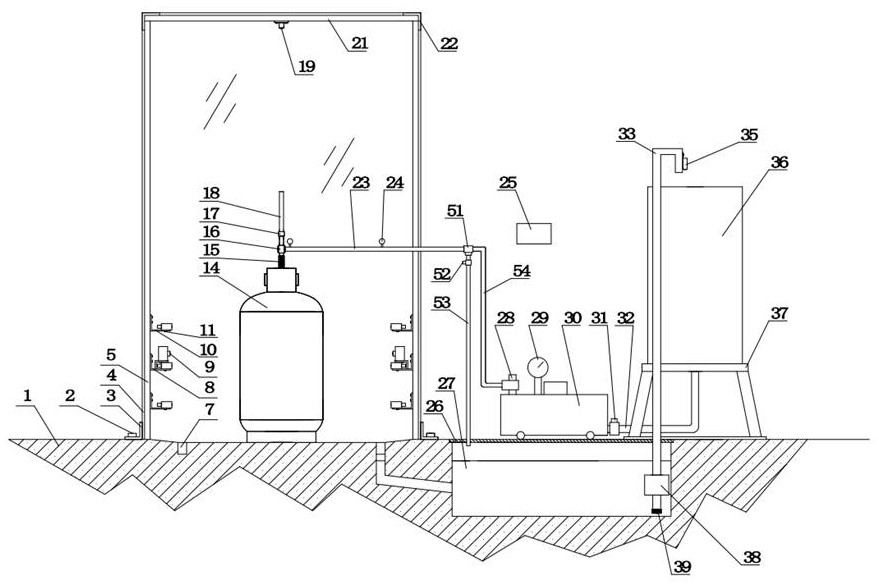

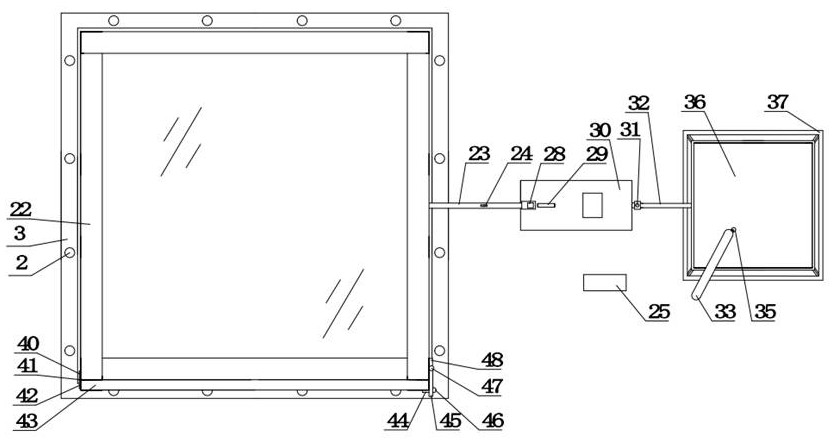

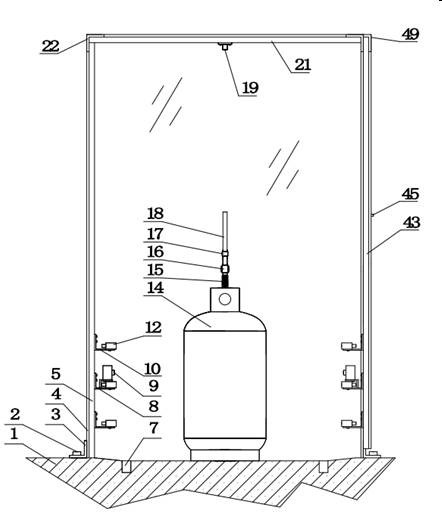

A cart-type fire extinguisher cylinder pressure alternating and blasting test device

ActiveCN107638650BReduce manual operationsHigh degree of automationFire rescueMeasurement deviceFire extinguisher

The invention discloses a trolley-type fire extinguisher cylinder pressure alternating and blasting test device, which includes a fire extinguisher cylinder sample, an explosion-proof chamber, a measuring device, a pressurizing pipe and a pressure relief pipe. The fire extinguisher cylinder sample is placed in a closed In the explosion-proof room, there are measuring devices around the inner wall of the explosion-proof room. The measuring devices include a non-contact ultrasonic thickness gauge and a total station. The top of the fire extinguisher cylinder sample is connected to one end of the water inlet pipe, and the other end of the water inlet pipe passes through the explosion-proof chamber and the booster pipe. Connection, the booster pipe is connected to the bottom of the capacity cylinder through the booster pump, the water inlet pipe is connected to the pressure relief pipe, the pressure relief pipe is connected to the storage tank, the storage tank circulates the water back to the volume cylinder through the upper water pipe, and the outlet end of the upper water pipe is installed with ultrasonic water depth temperature tester. The present invention reduces manual operation and improves automation degree and test accuracy.

Owner:山东海诺知识产权运营管理有限公司

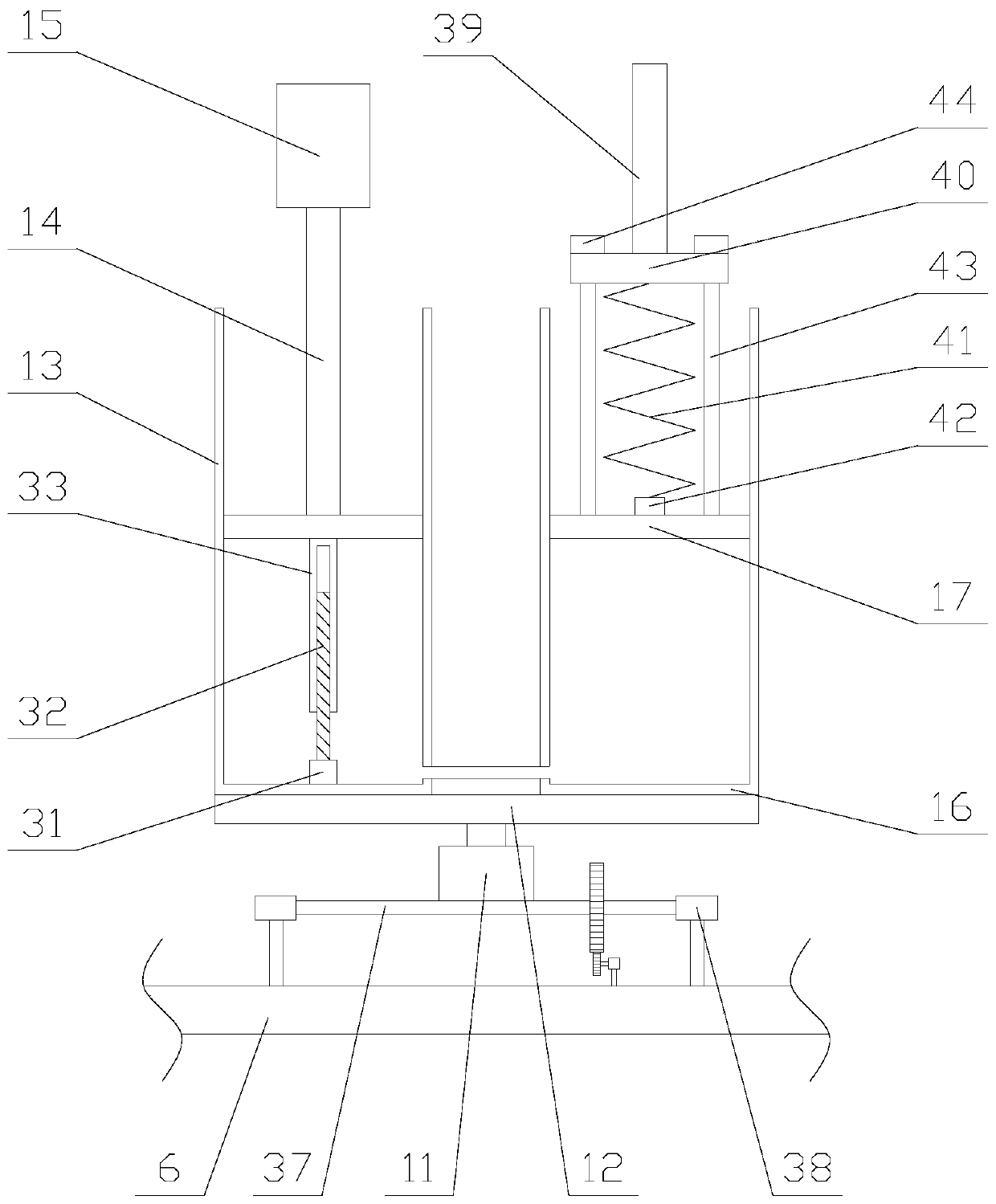

An ultrasonic thickness gauge with a stable contact between the probe and the workpiece

ActiveCN111307083BAchieve the effect of not needing to hold handsWide adaptationUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterEngineering

Owner:上海恩迪检测控制技术有限公司

An Ultrasonic Thickness Gauge That Can Avoid Dirt Impurities Affecting Measurement Accuracy

ActiveCN111397553BAffect measurement accuracyHigh measurement accuracyUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterEngineering

Owner:泰隆尔测控工程(武汉)有限公司

An ultrasonic thickness gauge with couplant recovery function

ActiveCN113776472BAvoid duplication of workImprove work efficiencyUsing subsonic/sonic/ultrasonic vibration meansConveyor partsThermodynamicsPachymeters

The invention relates to the technical field of testing instruments, in particular to an ultrasonic thickness gauge with a coupling agent recovery function. The problem to be solved is that the existing ultrasonic thickness gauge cannot recover all the couplants at one time, nor can it realize the classified recovery of couplants in different states, and the recovered couplants in different states are mixed with each other. Technical solution: An ultrasonic thickness gauge with a coupling agent recovery function, including a propulsion support system and a pollution layer recovery system, etc., and a pollution layer recovery system is installed on the propulsion support system. The present invention recovers all couplants at one time, avoids duplication of work, improves work efficiency, synchronizes and sorts recovery of couplants in different states, avoids mixing of couplants in different states, and improves recovery of couplants Quality, the effect of reducing the difficulty of processing work.

Owner:胜利油田东强机电设备制造有限公司

Ultrasonic Thickness Gauge for Metal Composite Materials

ActiveCN110006997BImprove noise reductionHigh sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansData processing systemUltrasonic pachymeter

The present invention aims at the problem that the thickness of a single layer of metal of a metal composite material cannot be measured and the overall thickness of the metal composite material cannot be measured in the prior art, and provides a metal composite material ultrasonic thickness measurement capable of measuring the thickness of each layer of the metal composite material Instrument, which includes a voltage adjustable power supply, an ultrasonic transmitting module, an ultrasonic receiving module, a data acquisition module, and a data processing system. The power supply provides power for the ultrasonic transmitting module, the ultrasonic receiving module, the data acquisition module, and the data processing system. A kind of ultrasonic thickness gauge for metal composite materials, the accuracy and reliability can be guaranteed, and the thickness can be accurately measured even in some cases of poor coupling.

Owner:葫芦岛探克科技有限公司

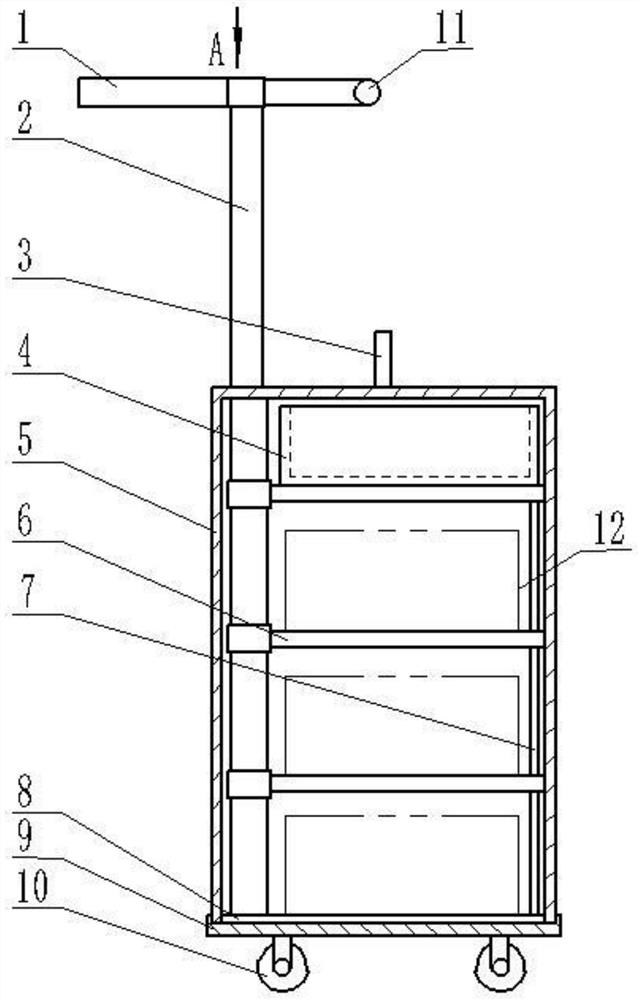

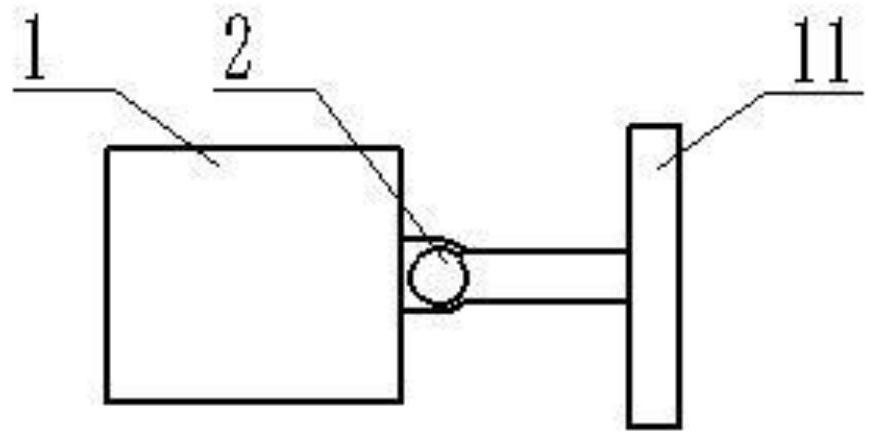

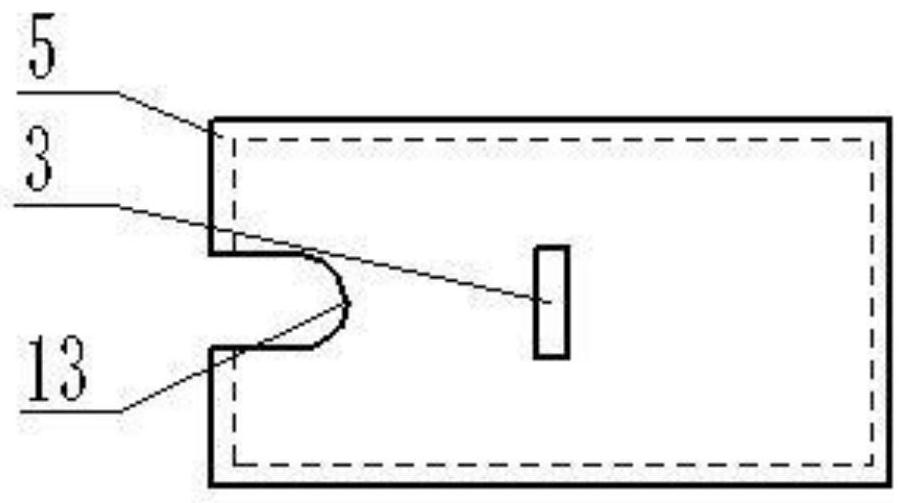

Special inspection device for boiler pressure vessel

PendingCN114719796ARealize leak checking and fillingEasily implement leak detection and fillingNuclear energy generationUsing subsonic/sonic/ultrasonic vibration meansSpectrum analyzerUltrasonic pachymeter

The invention discloses an inspection device special for a boiler pressure vessel, and mainly relates to the technical field of inspection devices, the inspection device comprises a plurality of inspection devices, the inspection devices comprise an ultrasonic thickness gauge, a hardness meter and a spectrum analyzer, the inspection device also comprises a moving assembly, and the plurality of inspection devices are all placed in the moving assembly in a removable manner. The moving assembly is of a multi-layer box body structure capable of being opened and closed and is used for gathering and storing various inspection devices and carrying the inspection devices to move and transition. The movable assembly is arranged, various inspection devices are integrated and stored into a whole, convenience is achieved, and before inspection or transition, leakage checking and vacancy filling of the inspection devices are easily achieved according to the placement positions of the multiple inspection devices; inspection equipment is placed on the partition plates, is rotationally pulled out during inspection and is pushed back to the partition plates when not in use, so that the inspection equipment is convenient to take, and is simple in overall structure, efficient and convenient.

Owner:杜焕香

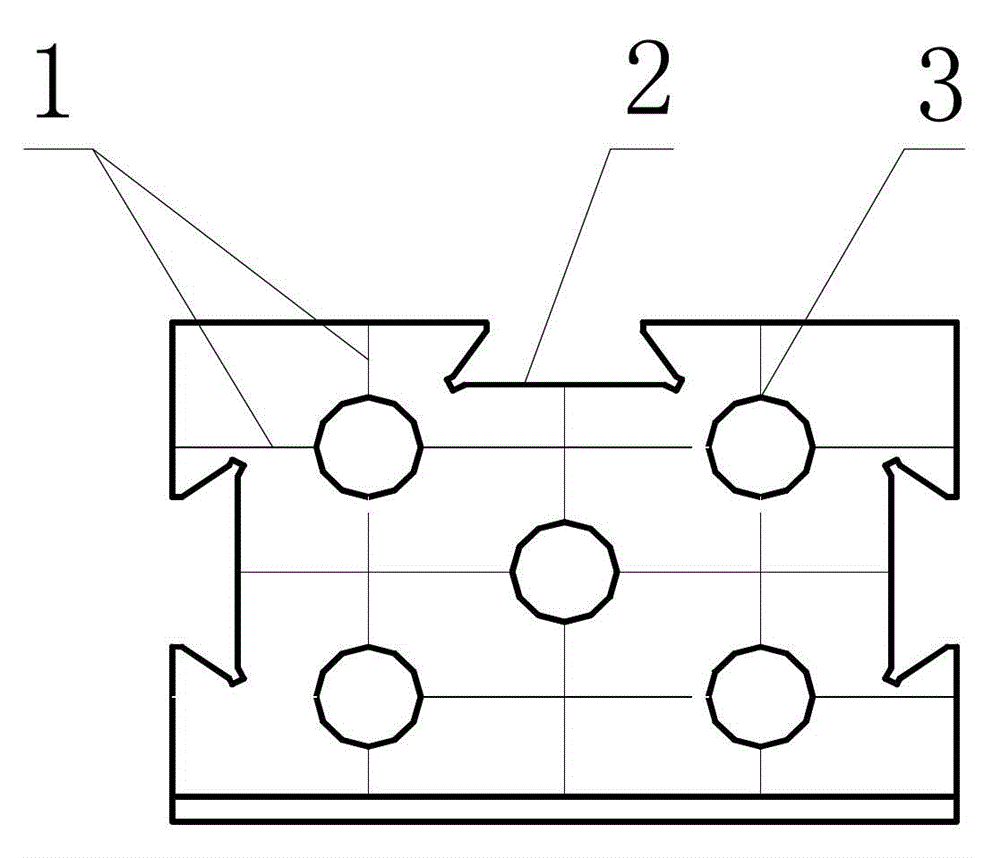

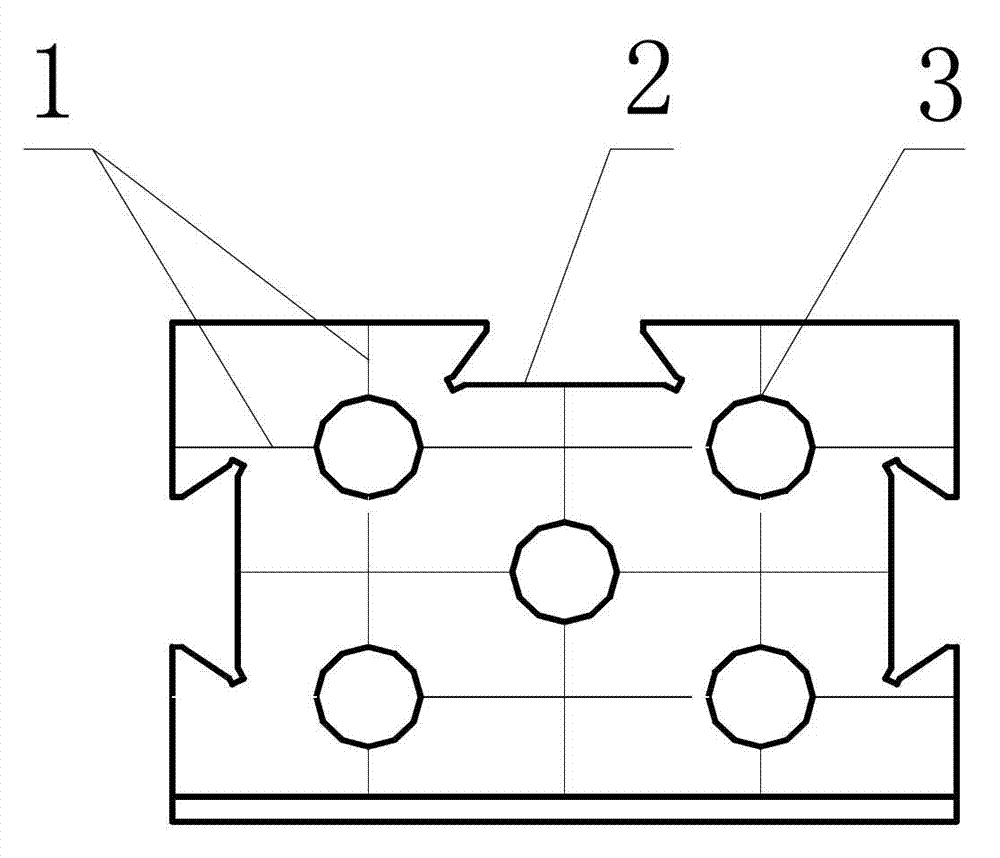

Quick positioned detecting method for thickness size of variable thickness part and auxiliary detecting device

ActiveCN102980540BImprove detection efficiencyReduce testing costsUsing subsonic/sonic/ultrasonic vibration meansVariable thicknessUltrasonic pachymeter

The invention provides a quick positioned detecting method for a thickness size of a variable thickness part and an auxiliary detecting device. Firstly, a plate-shaped auxiliary detecting device provided with a right-angle bending edge is produced, and array holes regularly arranged by a plurality of different detecting points and hole center longitude and latitude scribed lines are formed on the plate surface of the auxiliary detecting device; and then, the hole system positions on the plate surface of the auxiliary detecting device are leant against and bonded on a plane to be detected of the variable thickness part, a positioning reference hole (9) is determined in end holes of the hole system, and a Y-direction size scribed line (7) and an X-direction size scribed line (8) are scribed on the part to be detected respectively; the Y-direction size scribed line and the X-direction size scribed line are aligned to the hole center longitude and latitude scribed lines of the hole system when detecting; and finally, different positions of the hole system are touched by a probe of an ultrasonic thickness meter to obtain thickness values which are obtained by measuring. The auxiliary detecting device comprises an L-shaped mother board which is provided with a right-angle bending edge, and combination son boards extending to two sides; and the whole surface of the device is provided with a regular hole system, and dovetail grooves and dovetail bosses for positioning and connection.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

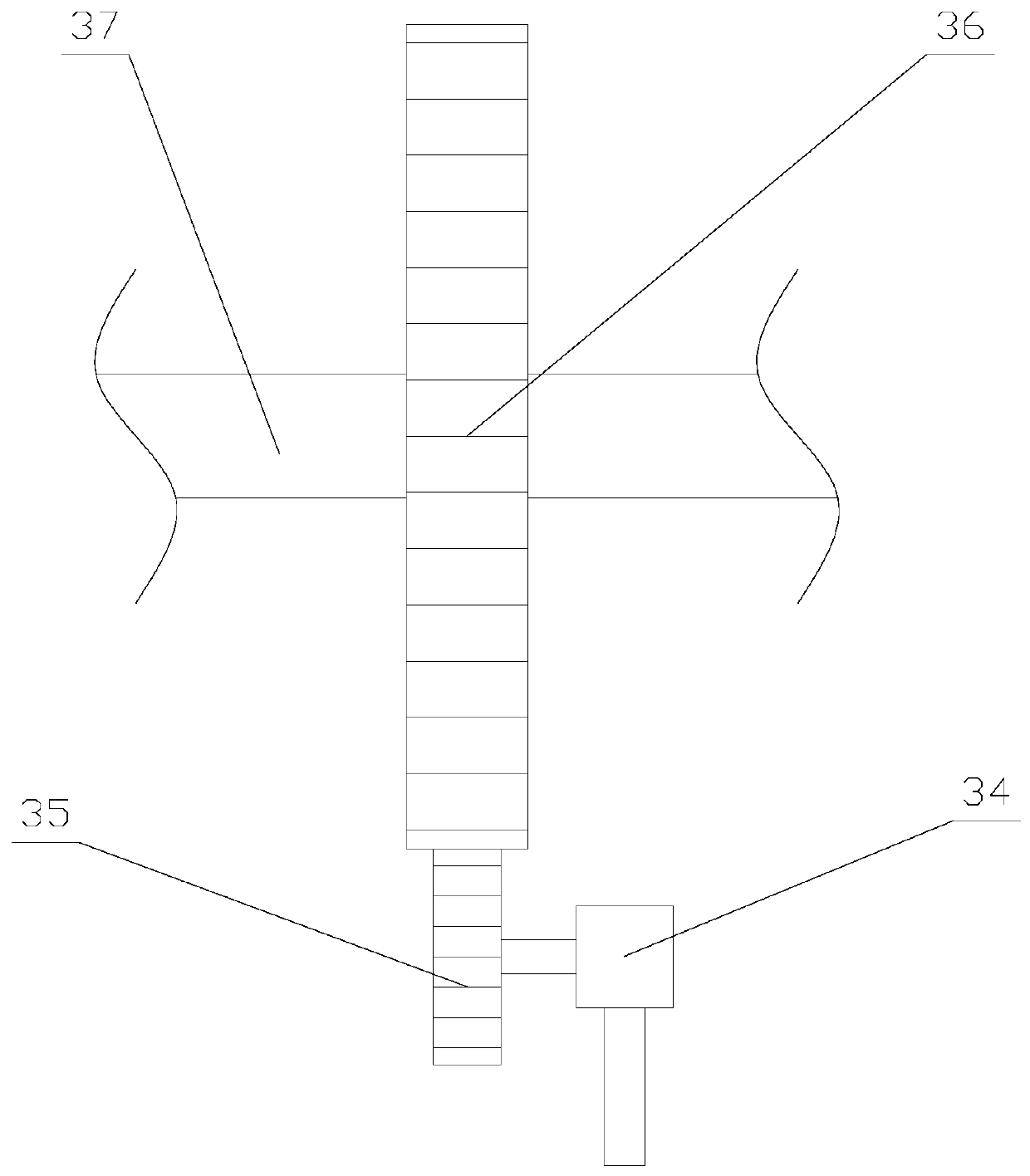

An Ultrasonic Thickness Gauge with Marking Function for Small Pipes

ActiveCN108458676BAchieve fixationLoading and unloadingUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterAir pump

The invention relates to an ultrasonic thickness gauge having the marking function and being suitable for small pipelines. The ultrasonic thickness gauge comprises a body, a telescoping mechanism, a sliding rod, a moving board and two detection mechanisms, wherein the detection mechanisms comprise struts, curved boards, rotating assemblies, rotating boards, support boards, probes, label assembliesand multiple fastening assemblies, the fastening assemblies comprise multiple fastening units, the fastening units comprise first motors, first driving shafts, sleeves and fastening blocks, and the label assemblies comprises first rings, second rings, air pumps, air bags, second motors, first connection rods, second connection rods and label pens. The ultrasonic thickness gauge is advantaged in that pipelines are fixed through fixing assemblies, the probes are made to measure in a vertical angle, measurement precision is improved, moreover, the label pens are made to move at the desired position through the label assemblies for labeling, a detector is convenient to master the pipeline situations, and device practicality is improved.

Owner:东营市鑫海石油装备有限公司

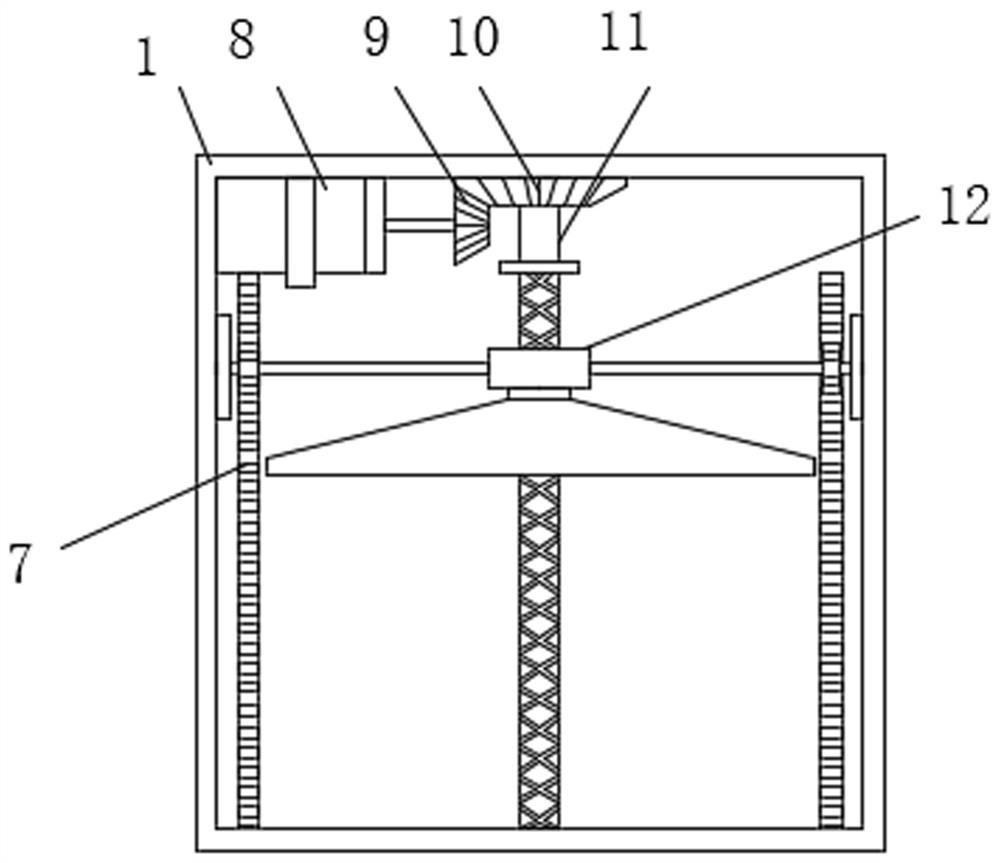

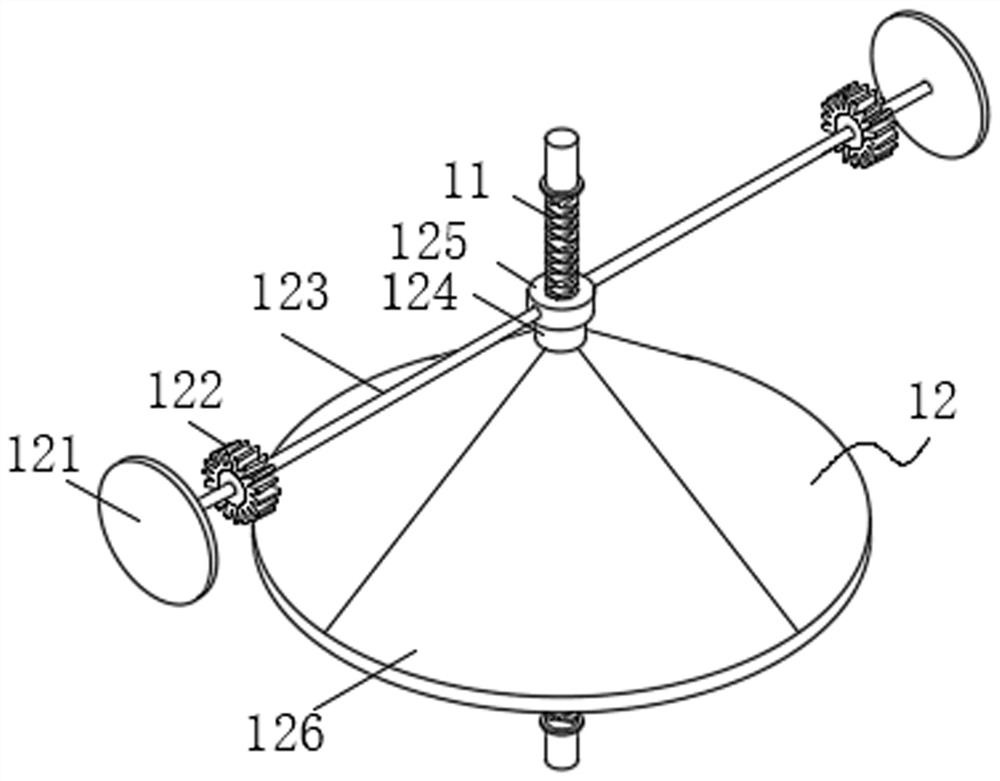

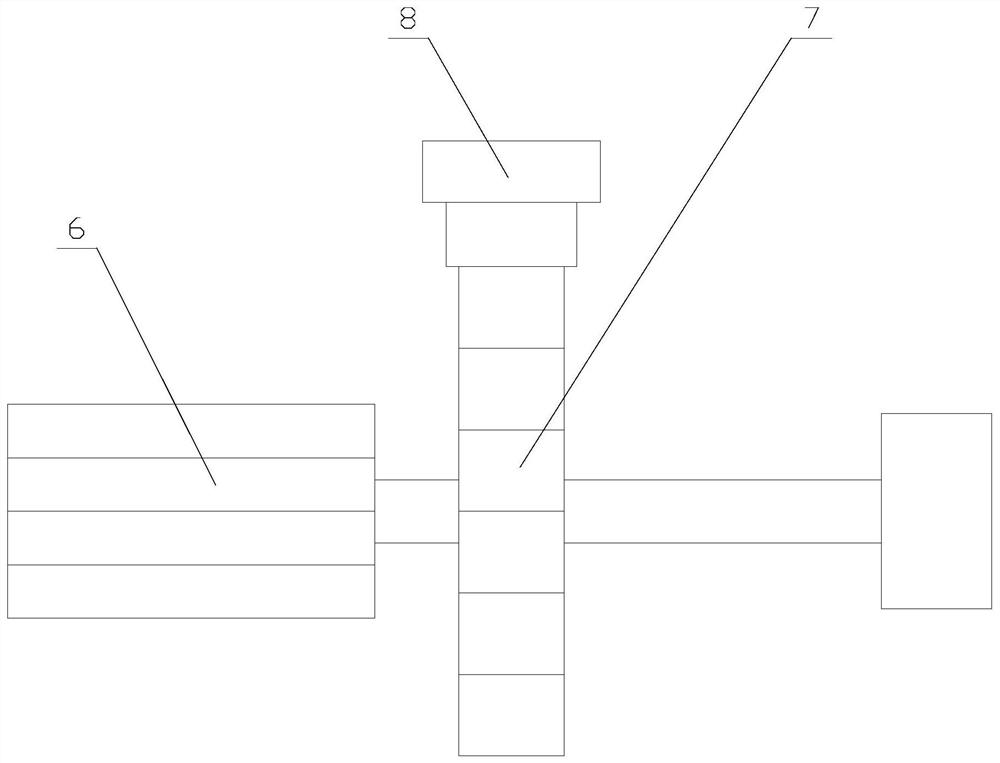

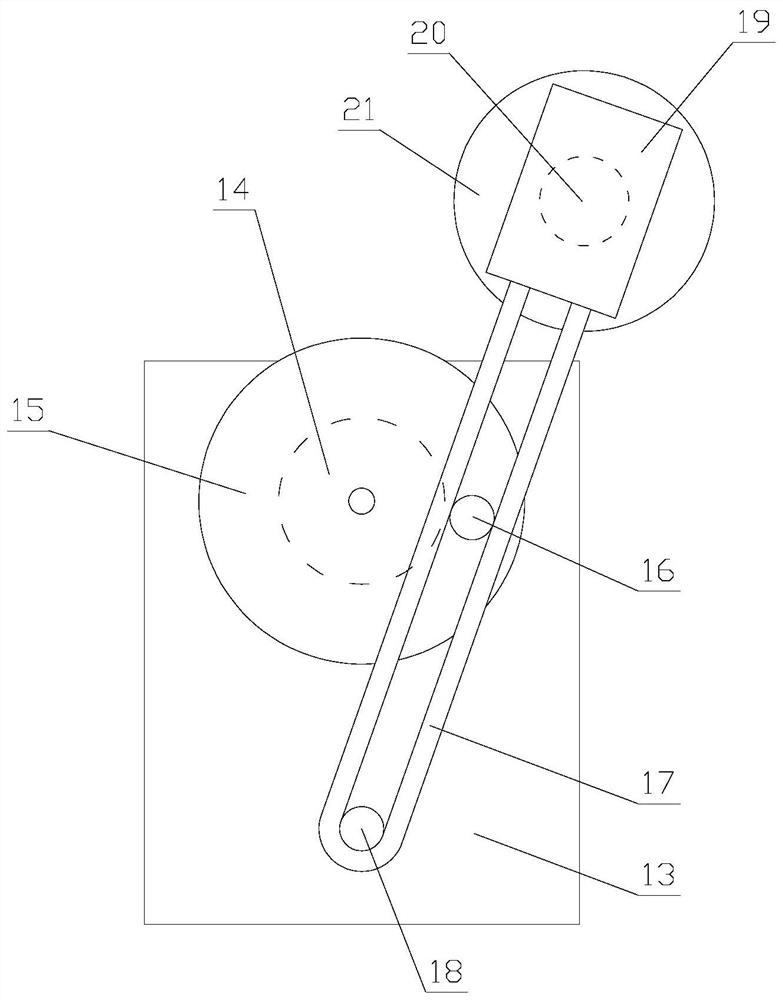

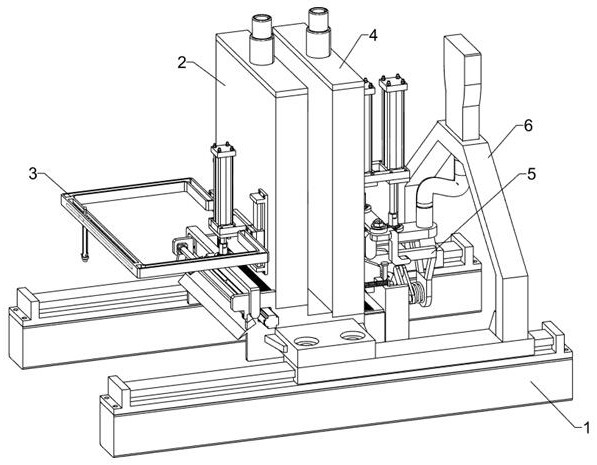

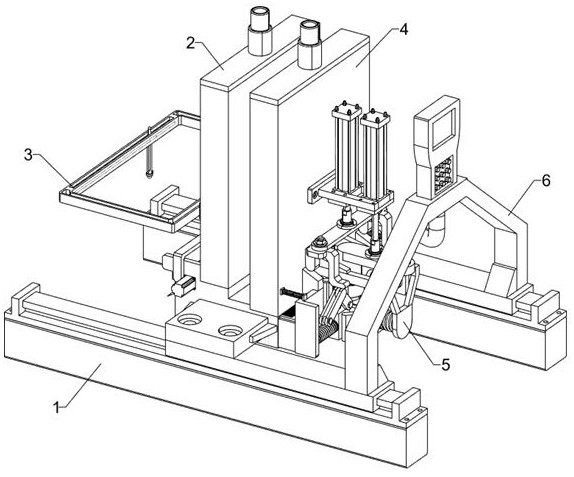

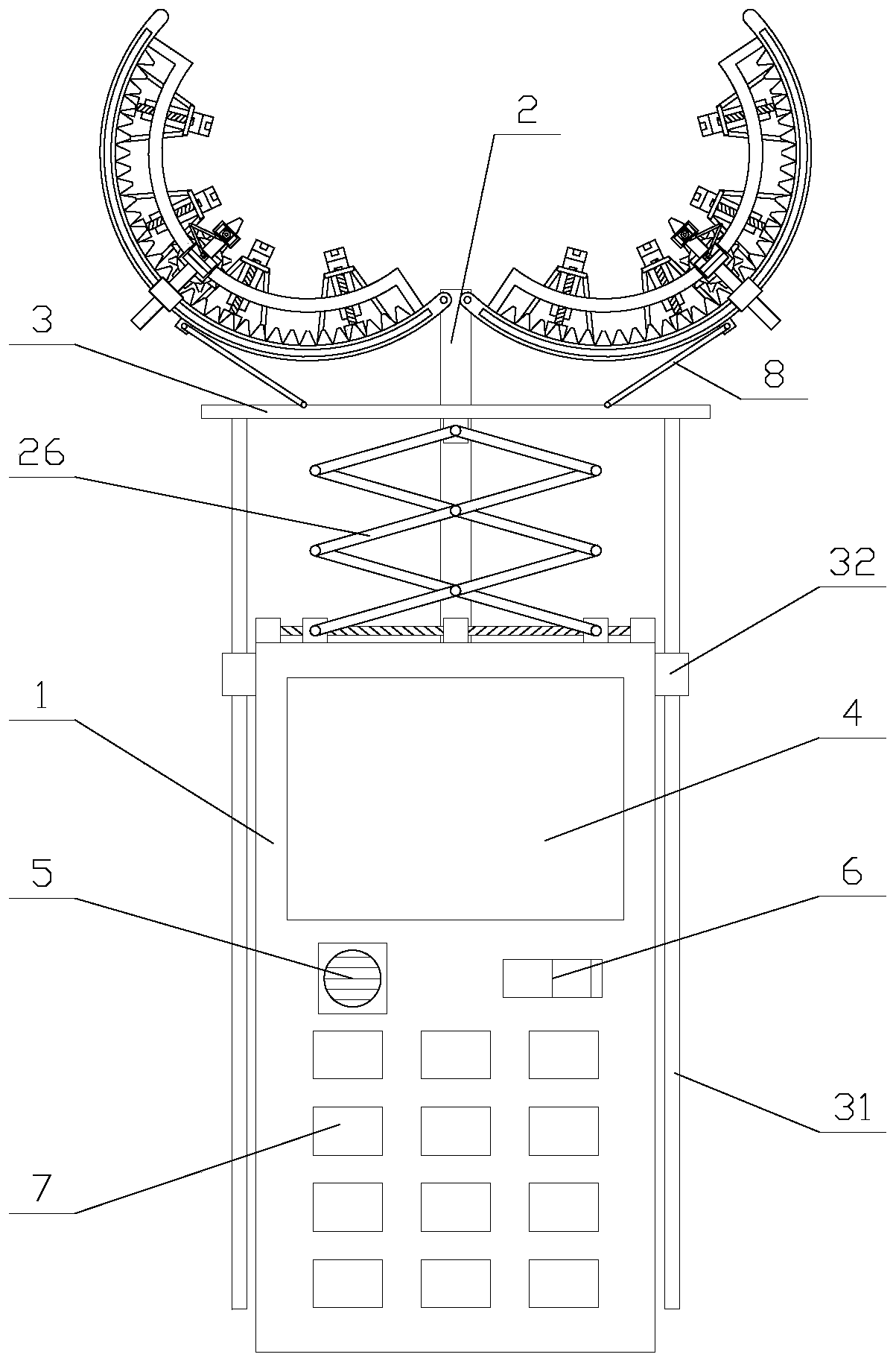

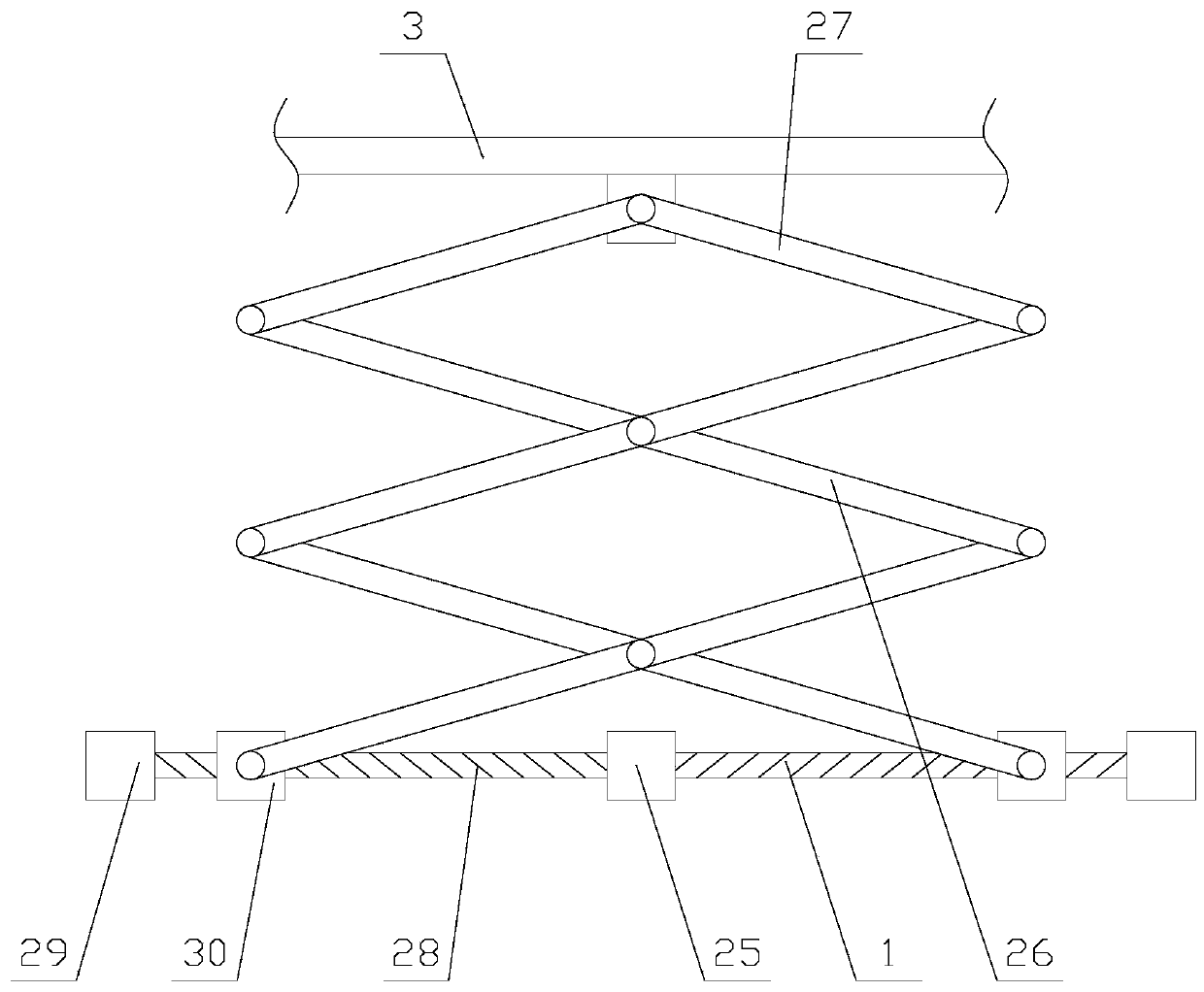

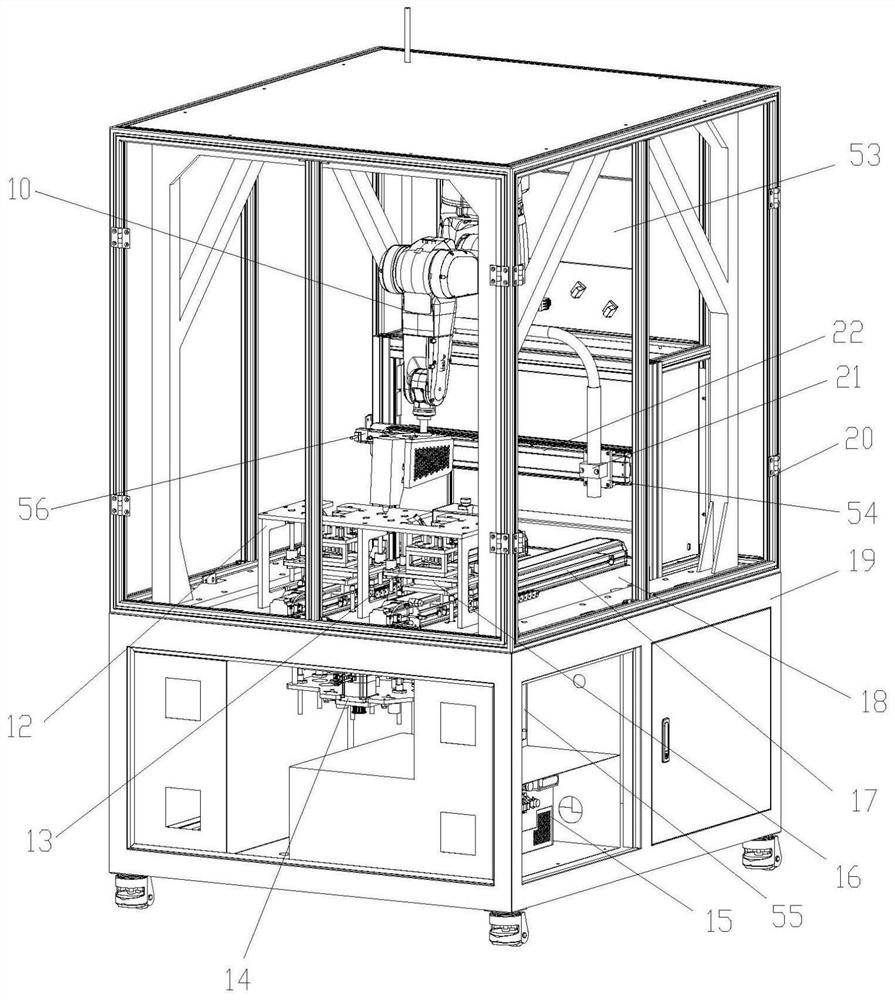

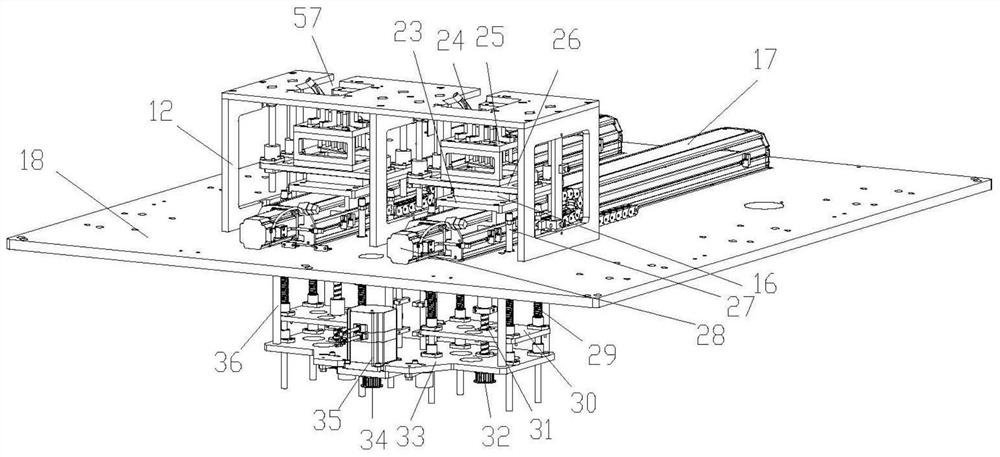

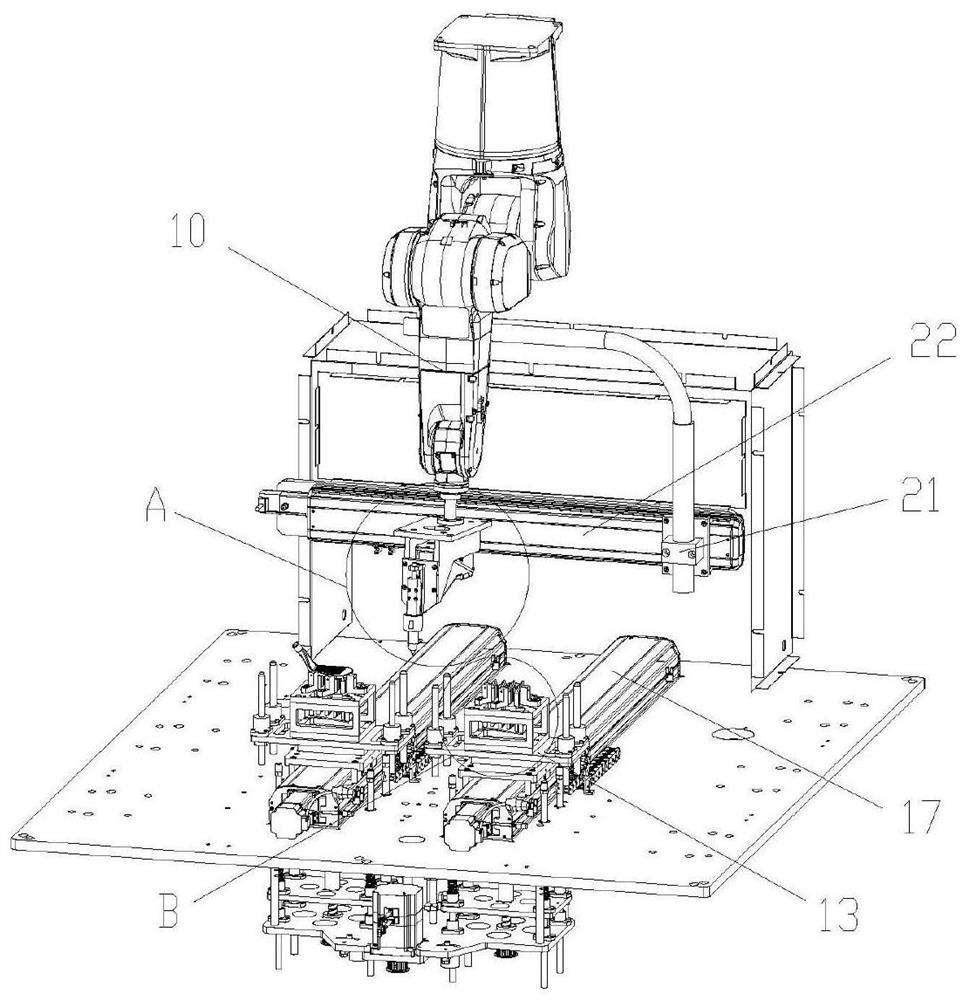

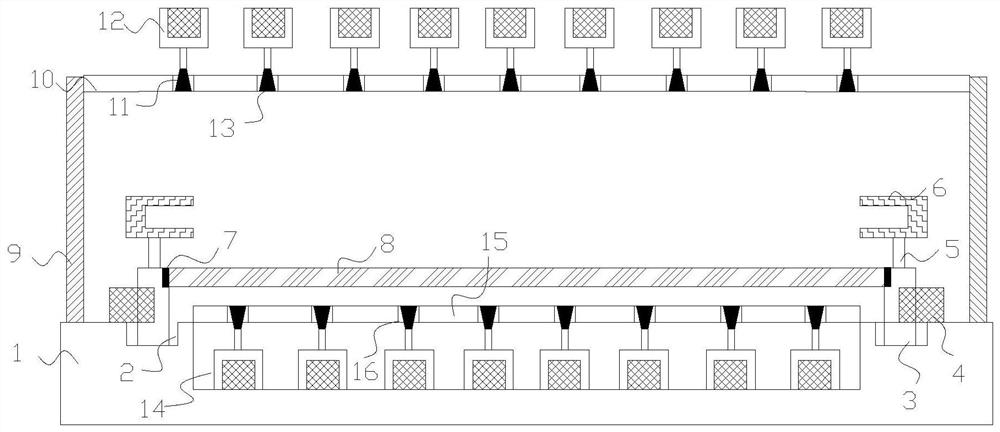

Golf club head hitting surface automatic detection equipment

PendingCN112539719AImprove accuracyImprove detection efficiencyUsing subsonic/sonic/ultrasonic vibration meansTypewriters3d sensorLine sensor

The invention provides golf club head hitting surface automatic detection equipment which comprises a case. A working platform is arranged in the case and a rack is arranged on the working platform. The equipment further comprises a detection structure, a six-axis manipulator, an ultrasonic probe, an ultrasonic thickness gauge, an infrared 3D sensor, an X-axis linear module, an ink-jet printer, aPLC program control system, an industrial personal computer master control system and a jig lifting structure. The detection structure, the six-axis manipulator, the ultrasonic probe, the ultrasonic thickness gauge, the X-axis linear module and the ink-jet printer are respectively connected with the industrial personal computer master control system and the PLC program control system; and the PLCprogram control system is arranged in the case and is positioned below the working platform. The beneficial effects of the equipment are that the equipment achieves the automatic detection of weight,thickness, flatness, abrasive belt marks, offset and edge collapse, is high in detection accuracy, and greatly improves the detection efficiency.

Owner:FENGTAI INTELLIGENT CONTROL SHENZHEN CO LTD

Ultrasonic thickness gauge capable of preventing dirt and impurities from influencing measurement accuracy

ActiveCN111397553AAffect measurement accuracyHigh measurement accuracyUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterEngineering

The invention relates to the technical field of thickness gauges, and discloses an ultrasonic thickness gauge capable of preventing dirt and impurities from influencing the measurement accuracy. The thickness gauge comprises a thickness gauge body, movable seats are fixedly mounted at the two sides of the top end of the thickness gauge body, a mounting plate is movably mounted at the other ends ofthe movable seats, a positioning plate is fixedly mounted at the bottom end of the mounting plate, and scraper blades are fixedly mounted at the two ends of the positioning plate. According to the ultrasonic thickness gauge capable of preventing dirt and impurities from influencing measurement accuracy, during use, the positioning plate is in contact positioning with a to-be-measured surface; then dirt and impurities on the surface are scraped off through a scraper blades; as the thickness gauge body is movably connected with the movable seats through movable columns, the thickness gauge bodyis rotated to the position right facing the measuring surface, and then a threaded column is rotated so that a limiting column of a mounting seat is rotated to the mounting seat to correspond to a limiting hole, the thickness gauge has the advantages of being high in measuring precision and the like, and the problem that errors are prone to occurring in the prior art is solved.

Owner:泰隆尔测控工程(武汉)有限公司

Thickness testing equipment for wooden door production

ActiveCN110672048BSimple structureSimple and fast operationUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterElectric machinery

Owner:衡东振好木制品有限公司

An Easy-to-operate Ultrasonic Thickness Gauge

ActiveCN108709517BFlexible structureAchieve fixationUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterElectric machinery

The invention relates to an ultrasonic thickness meter convenient to operate. The ultrasonic thickness meter comprises a main machine, a connecting line, a holding rod, a push plate and a thickness measuring device and is characterized in that the thickness measuring device comprises a thickness measuring mechanism and a plurality of fixing mechanisms, each fixing mechanism comprises a telescopingcomponent, a moving plate, a direction adjusting component, an air suction chamber, an air suction pipe and a sucker, the thickness measuring mechanism comprises a rotating component, a first motor,a rotary disc, a thickness measuring component and a scanning component, the thickness measuring component comprises a first air cylinder, a first piston, a moving unit and a probe, and the scanning component comprises a second air cylinder, a second piston and a scanning unit. The ultrasonic thickness meter the suckers are allowed to attach to the surface of a to-be-measured object through the fixing mechanisms so as to fix the push plate, and the two hands of a measuring worker can be freed to do other work; in addition, the thickness measuring mechanism adjusts the angle of the probe afterthe surface shape of the to-be-measured object is determined to allow the probe to vertically aim at the to-be-measured object so as to increase the measuring precision of the ultrasonic thickness meter.

Owner:东营中达石油设备有限公司

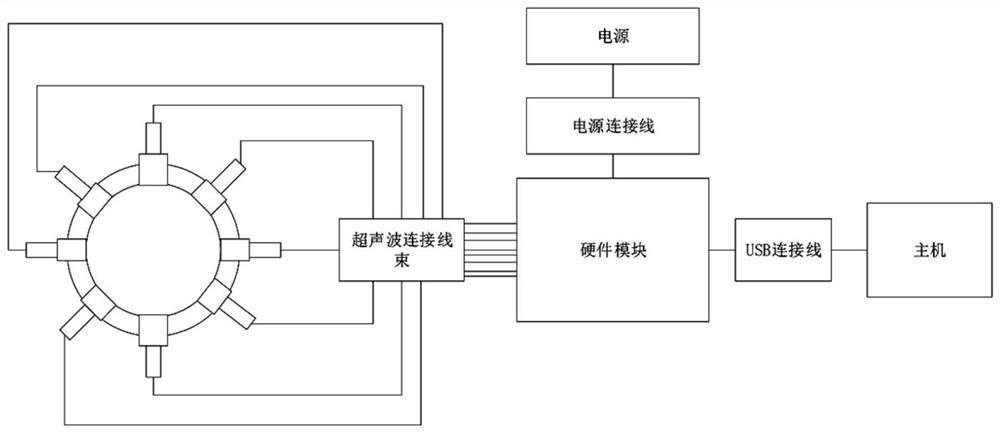

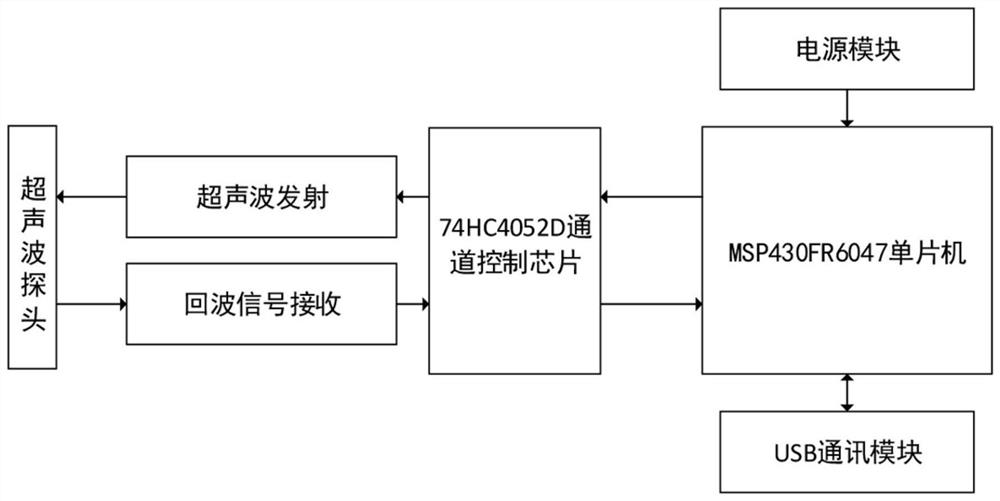

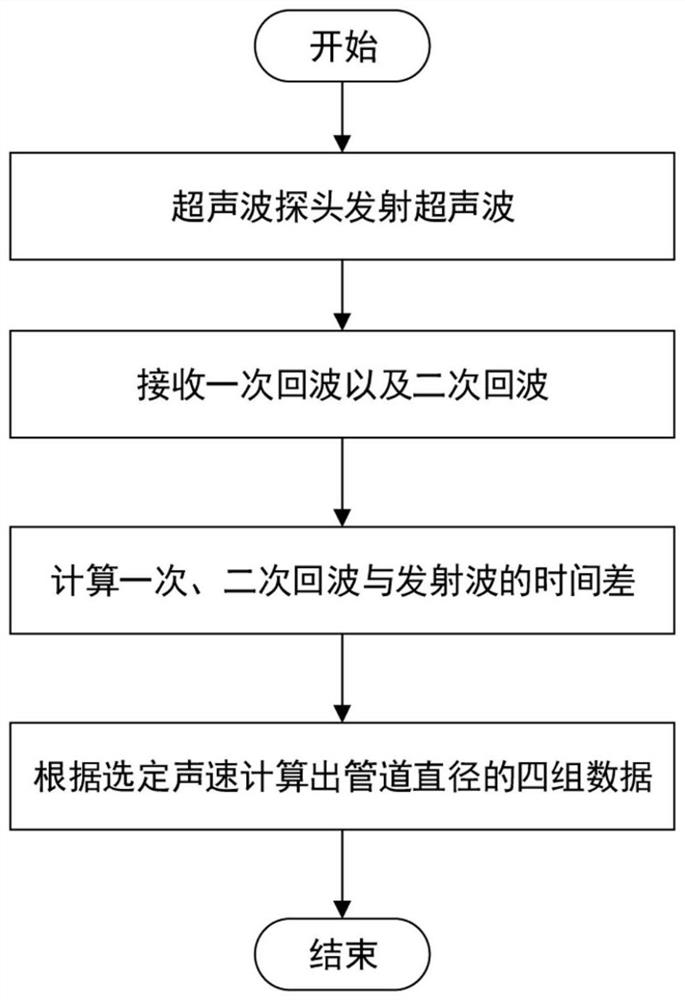

Multichannel flow cross section detection device and detection method

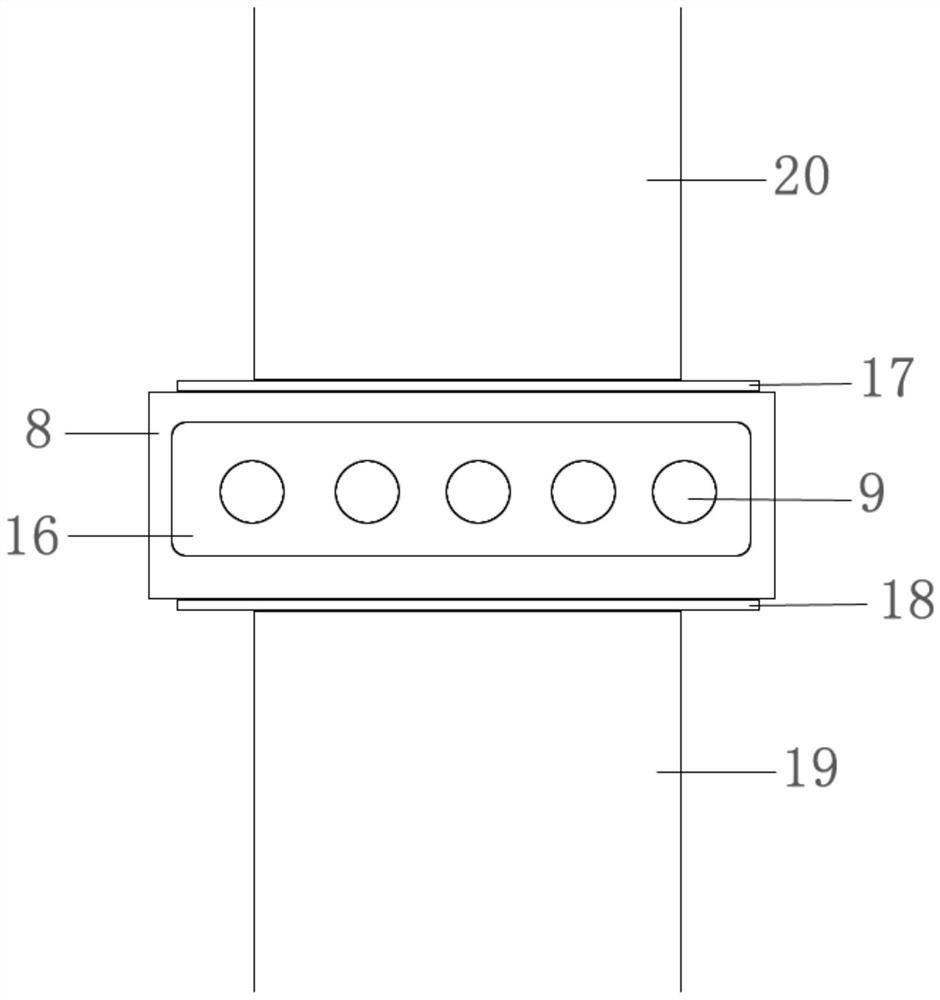

PendingCN114034267AReduce calculation errorsHigh measurement accuracyUsing subsonic/sonic/ultrasonic vibration meansUltrasonic pachymeterAcoustics

The invention provides a multichannel flow cross section detection device and a detection method. N ultrasonic probes are uniformly arranged on the same cross section of the side wall of a pipeline, the N ultrasonic probes are connected with a single chip microcomputer through a channel control module, and the channel control module is used for controlling the ultrasonic probes to work or not; the single chip microcomputer is connected with an upper computer through a USB communication module. Through the N ultrasonic probes, the inner diameter of the pipeline can be measured according to the principle of an ultrasonic thickness gauge and an ultrasonic tomography technology, and then the area of the cross section of the pipeline can be calculated. On the basis of the ultrasonic tomography principle, an ultrasonic array is used for tomography. According to the method, the obtained ultrasonic information amount is large, the calculation method is advanced, the calculation error of the flow cross section is reduced, the measurement precision of the flow cross section is effectively improved, and a more accurate basis is provided for flow measurement.

Owner:HEBEI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com