Method for detecting wall thickness of turbojet engine high-pressure turbine blade through ultrasonic waves

A technology of turbojet engine and high pressure turbine, which is applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of inaccurate thickness measurement, stuck and blocked steel balls, excess material in the inner cavity of blades, etc. Real and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0023] A method for ultrasonically detecting the wall thickness of a high-pressure turbine blade of a turbojet engine, comprising the following steps:

[0024] S1. Equipment selection: choose an ultrasonic thickness gauge with waveform display, and the model of the ultrasonic thickness gauge is 25DLPLU;

[0025] S2, making the leaf back template and the leaf basin surface template, specifically includes the following steps:

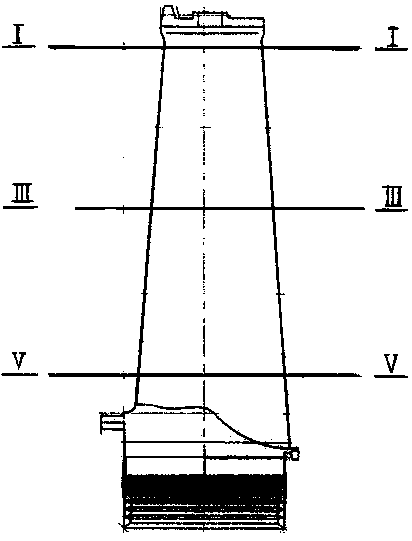

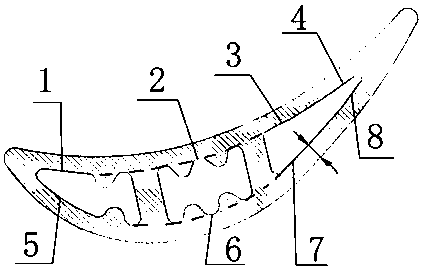

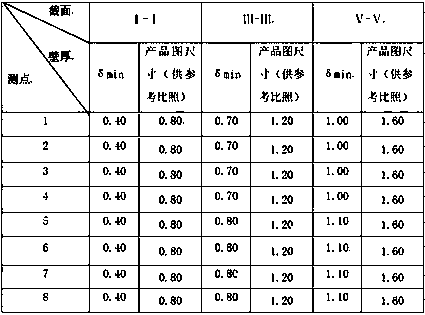

[0026] S21, according to the design drawing and the actual measurement size of the high-pressure turbine blade of the turbojet engine under test, compare and make the template on the back side of the blade and the template on the surface of the basin surface, so as to ensure that the template on the back side of the blade matches the back side of the blade of the high-pressure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com