Quick positioned detecting method for thickness size of variable thickness part and auxiliary detecting device

A technology of positioning detection and auxiliary detection, which is applied to measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve the problems that the inner shape surface cannot be converted, and the accuracy of the thickness of the variable thickness cannot be explained, so as to achieve detection Simple and convenient, saving detection cost and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

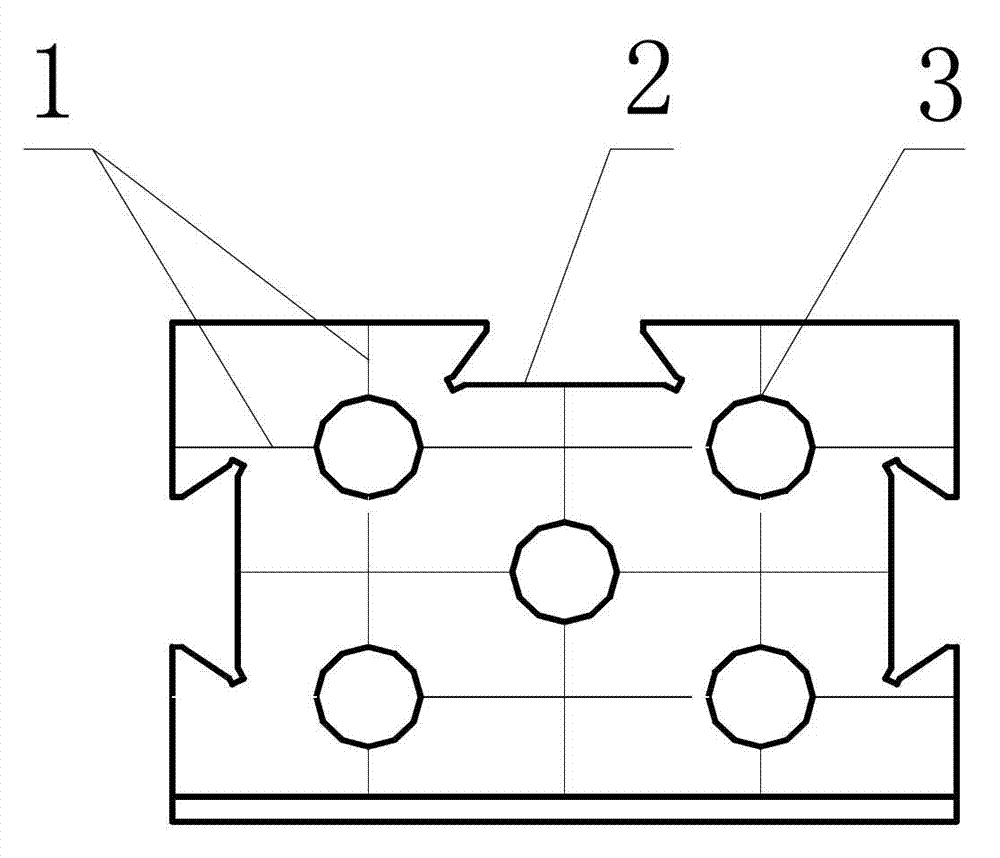

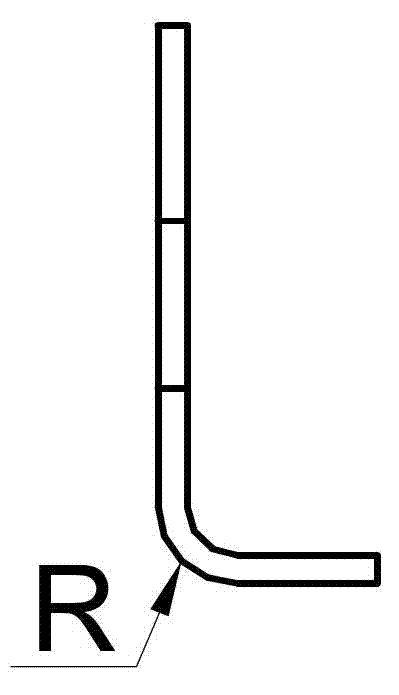

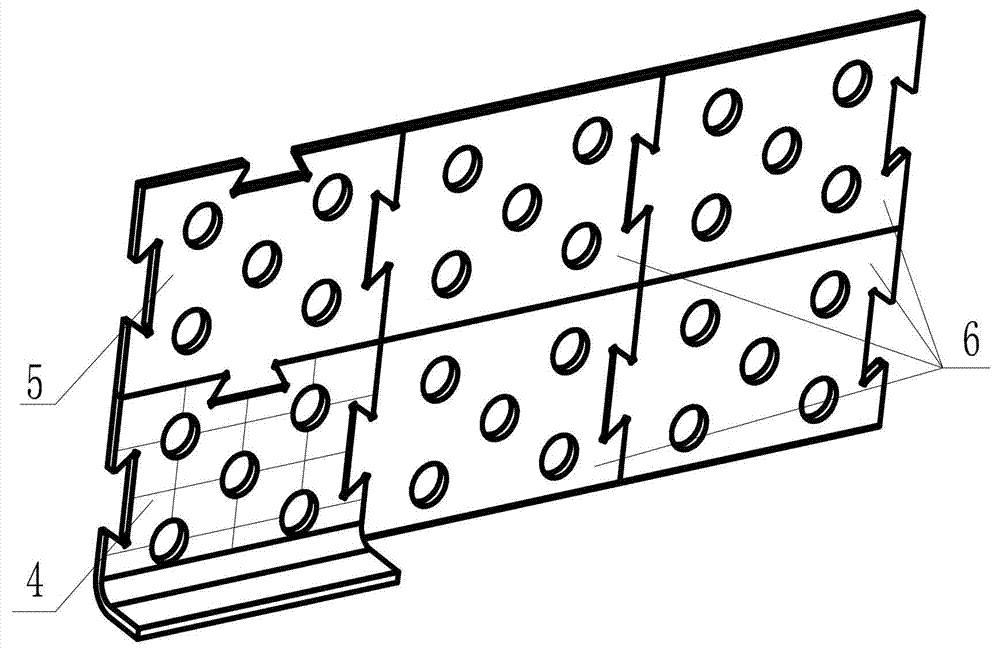

[0016] According to the present invention, first, according to the size of the variable thickness dimension surface of the part to be inspected, a plate-shaped hole system auxiliary detection device 10 with a right-angle bend is made, and the auxiliary detection device 10 has a plurality of different detection points on the plate surface. Regularly arranged array detection holes, before detection, determine a positioning reference hole 9 in the end hole of the above-mentioned hole system, and draw the central Y-direction dimension score line 7 of the reference hole 9 on the detection plane of the part 13 to be measured X-direction dimension line 8. During the detection process, align the latitude and longitude reticles of the holes in the auxiliary detection device 10 with the Y-direction dimension reticles 7 and X-direction dimension reticles 8 on the part 13 to be tested, and each hole on the board of the auxiliary detection device 10 Corresponding to different positions of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com