Multifunctional integrated ultrasonic detection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

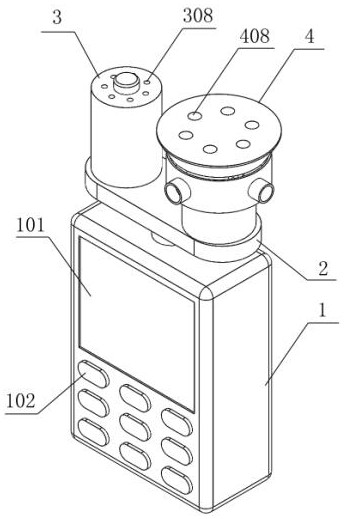

[0024] Multifunctional integrated ultrasonic testing equipment mainly includes ultrasonic thickness gauge host 1, bracket 2, ultrasonic probe device 3 and pneumatic grinding device 4.

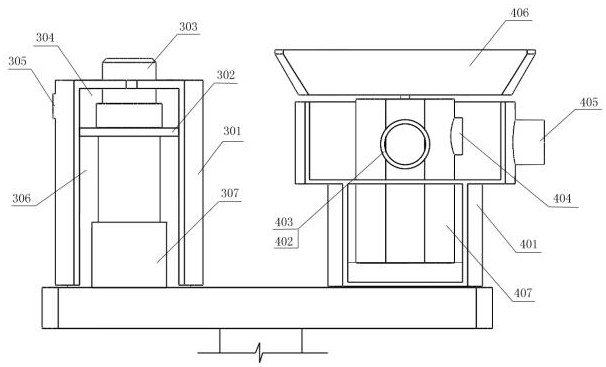

[0025] The bracket 2 adopts a T-shaped structure and is arranged on the top of the main unit 1 of the ultrasonic thickness gauge, and the ultrasonic probe device 3 is arranged at one end of the bracket 2, and the coupling agent spraying and ultrasonic thickness measurement can be performed simultaneously through the ultrasonic probe device 3; the ultrasonic probe device 3 includes Probe housing 301, the interior of probe housing 301 is provided with a partition 302, thereby dividing probe housing 301 into an upper chamber 304 and a lower chamber 306, the upper chamber 304 is used to store couplant, and the upper end of the side is provided with an inlet The feed port 305 is used for couplant filling, and a plug is set at the feed port 305 to close the feed port 305; the top surface of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com