Non-intrusive corrosion on-line detection equipment for fluorine chemical device

A detection equipment, non-invasive technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problem of poor continuous temperature resistance of thickness measuring probes Good reflection of corrosion trends, troublesome disassembly and installation of probes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

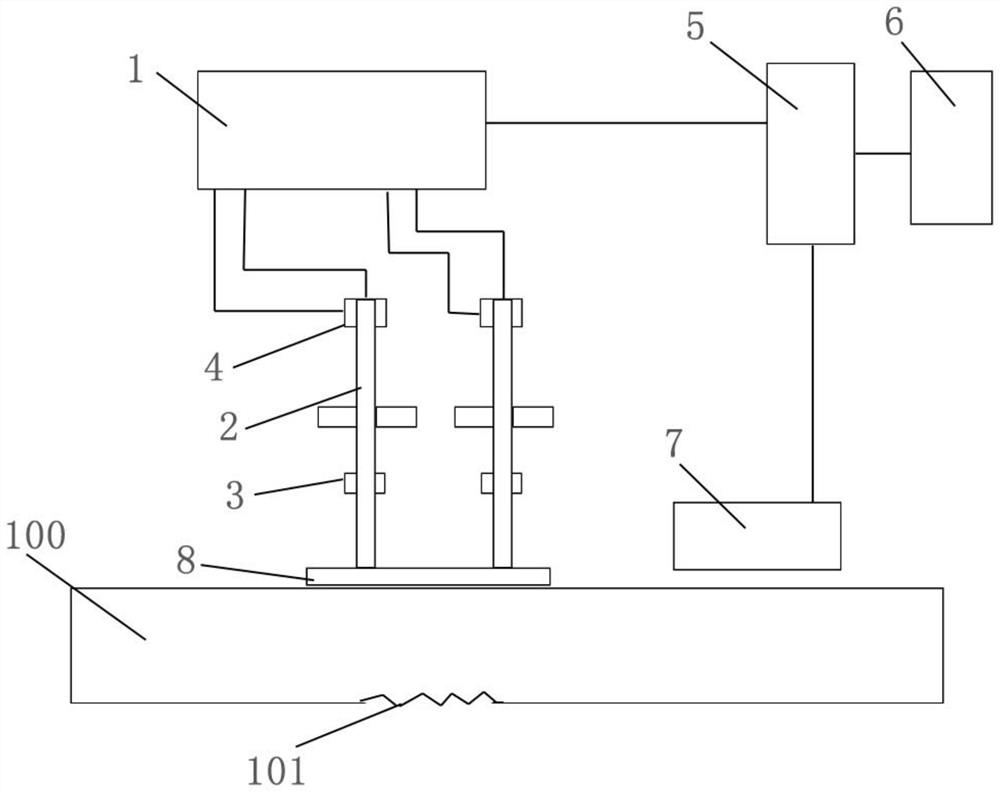

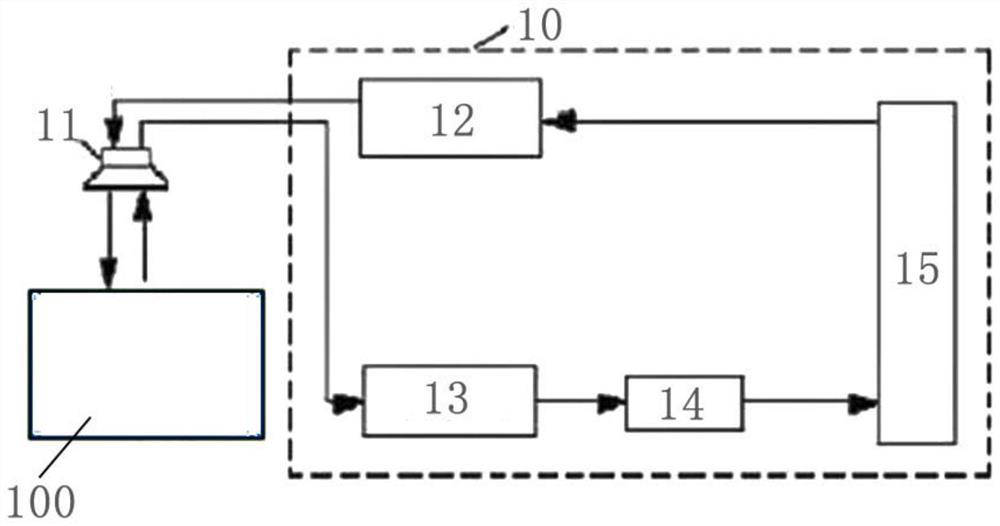

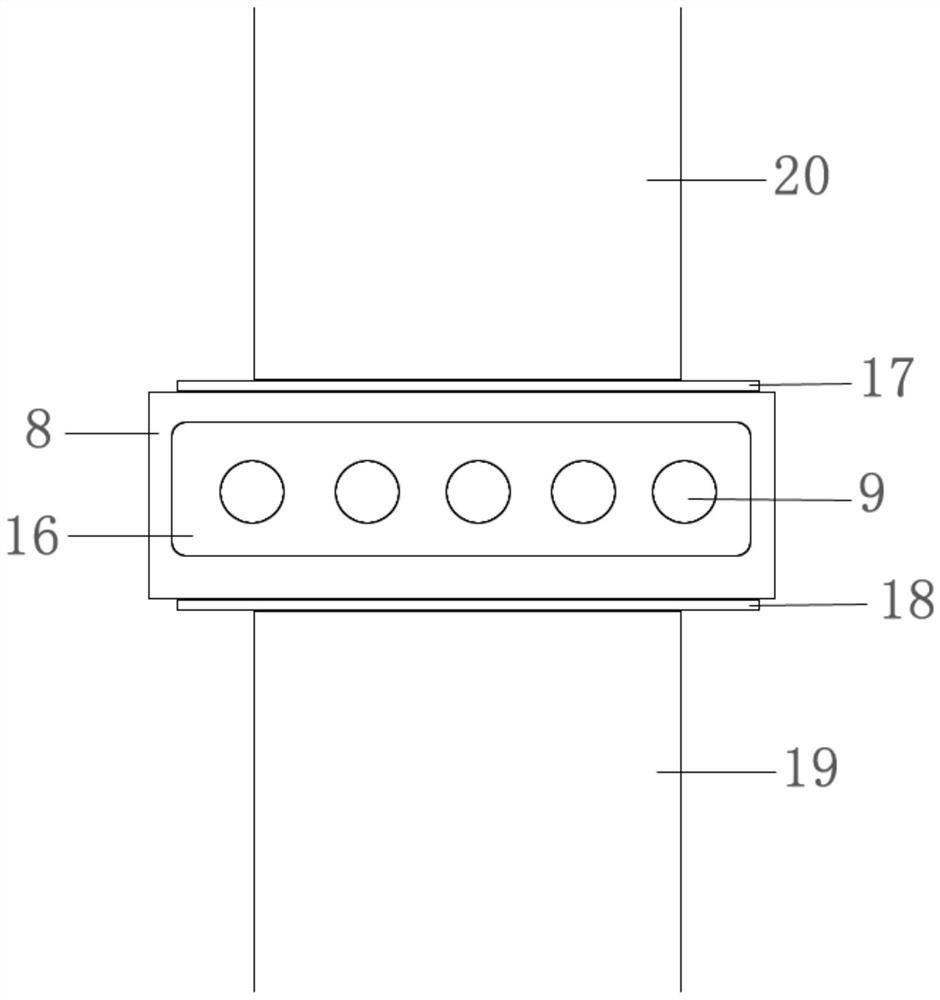

[0020] Such as figure 1 As shown, the non-invasive on-line corrosion detection equipment for fluorine chemical plant includes an ultrasonic detection module, a temperature compensation module, an ultrasonic data analysis module 1 , an ultrasonic thickness gauge 7 , a detection equipment host 5 and a display 6 . The detection equipment host 5 is connected to the ultrasonic thickness gauge 7 and the ultrasonic data analysis module 1 respectively, stores the received data, and displays it on the display 6 . The detection device host 5 can be a computer host.

[0021] The ultrasonic data analysis module 1 is connected with the ultrasonic detection module and the temperature compensation module, the ultrasonic detection module includes an ultrasonic transmitter, an ultrasonic receiver and a waveguide rod, and the ultrasonic transmitter contacts the pipeline through the first waveguide rod, The ultrasonic receiver is in contact with the pipeline through the second waveguide rod. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com