A cart-type fire extinguisher cylinder pressure alternating and blasting test device

A blasting test and fire extinguisher technology, which is applied in fire rescue and other fields, can solve the problems of low test quality and efficiency, cumbersome operation by personnel, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments to help those skilled in the art to have a more complete, accurate and in-depth understanding of the inventive concept and technical solutions of the present invention. The protection scope of the present invention includes but is not limited to In the following examples, any modifications made to the details and forms of the technical solutions of the present invention without departing from the spirit and scope of the present application fall within the protection scope of the present invention.

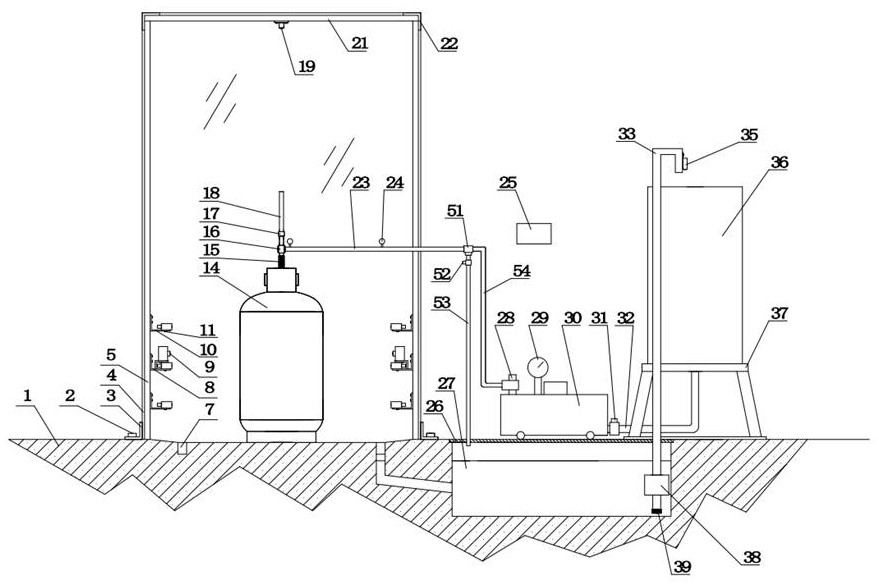

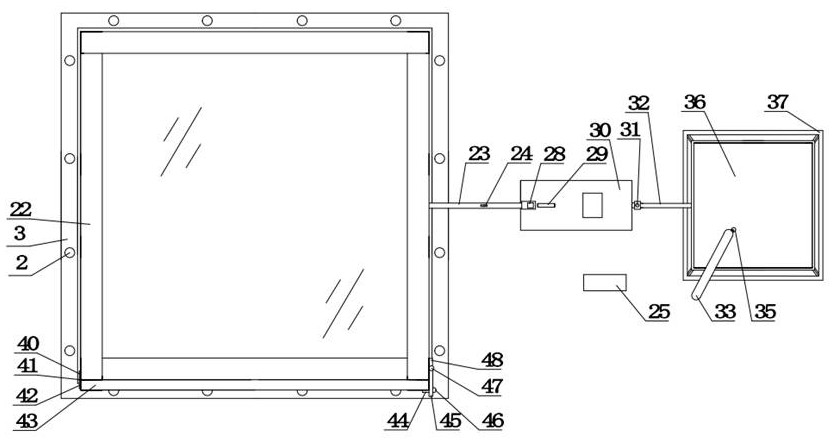

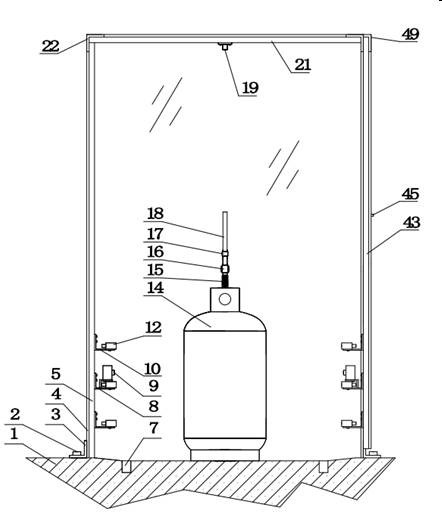

[0020] The accompanying drawing is an embodiment of the present invention. This embodiment includes a fire extinguisher cylinder sample 14 , an explosion-proof chamber 50 , a measuring device, a booster pipe 54 , and a pressure relief pipe 53 .

[0021] The explosion-proof chamber 50 is a rectangular parallelepiped, and is surrounded by four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com