Portable ultrasonic thickness meter

An ultrasonic and thickness gauge technology, applied in the field of sensor detection, can solve the problem that large-scale equipment or online systems are difficult to meet the requirements, and achieve the effects of small size, accurate measurement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

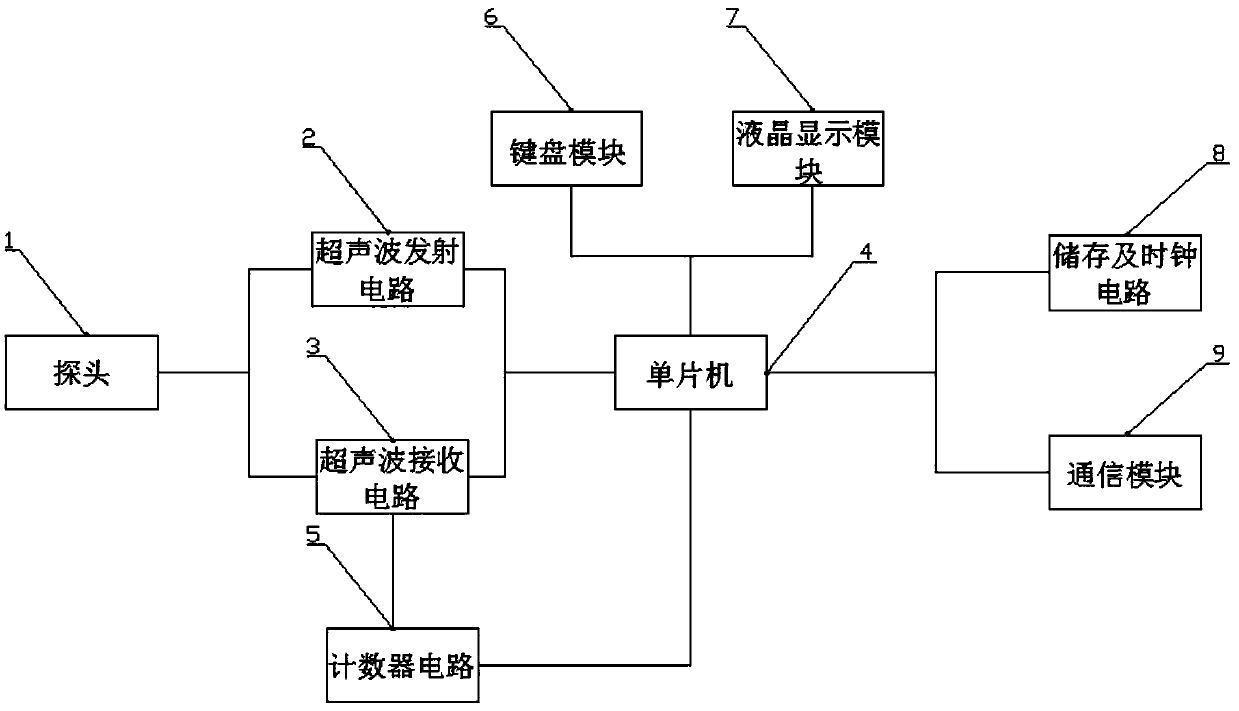

[0010] A portable ultrasonic thickness gauge is mainly composed of a probe 1, an ultrasonic transmitting circuit 2, an ultrasonic receiving circuit 3, a single chip microcomputer 4, a counter circuit 5, a keyboard module 6, a liquid crystal display module 7, a storage and clock circuit 8 and a communication module 9 It is characterized in that: the probe 1 is connected to the ultrasonic transmitting circuit 2, the ultrasonic receiving circuit 3 is connected to the probe 1, the ultrasonic transmitting circuit 2 and the ultrasonic receiving circuit 3 are connected to the single-chip microcomputer 4, the single-chip microcomputer 4 and the counter circuit 5 Connected, the counter circuit 5 is connected with the ultrasonic receiving circuit 3, the keyboard module 6 and the liquid crystal display module 7 are connected with the single-chip microcomputer 4, and the storage and clock circuit 8 and the communication module 9 are all connected with the single-chip microcomputer 4.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com